3D topographies are highly attractive for various applications in optics, fluidics, or biosciences, where a complex surface profile adds an improved functionality to elements or devices. However, current lithographies are often limited in pattern variety. Therefore structures are often fabricated using the combinations of different processes in a sequential way. Using grayscale lithography and selective thermal reflow, we are now able to fabricate patterns at the micro- and nanometer scale with different sizes, shapes, depths, and lateral extension on the same substrate as needed for various applications.

Grayscale lithography

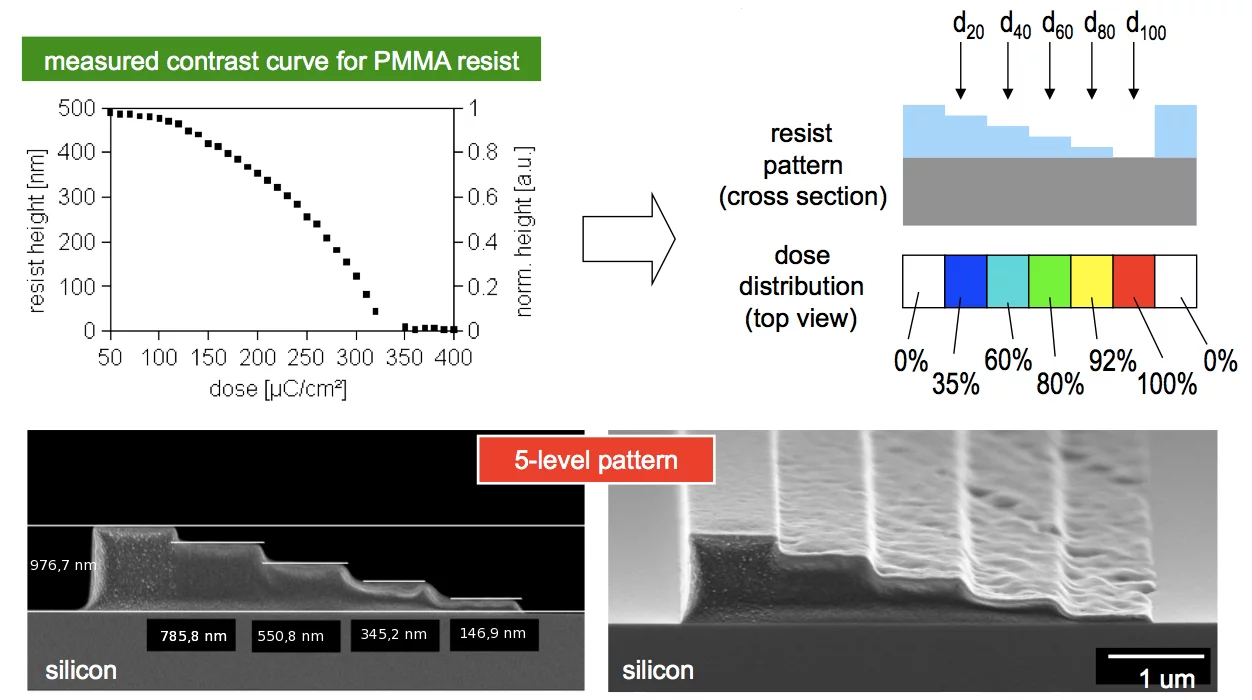

Exposure with electrons modifies the molecular weight of the resist and thus its etching characteristics in a solvent. A 3D profile with different height levels can be generated by local dose-modulation. For this, a CAD design with different layers is generated, each respresenting a different resist level. To each layer a dose is assigned according to a constrast curve calibrated for a specific resist, developer and time. The final dose assignment is done with specialized programs using proximity correction.

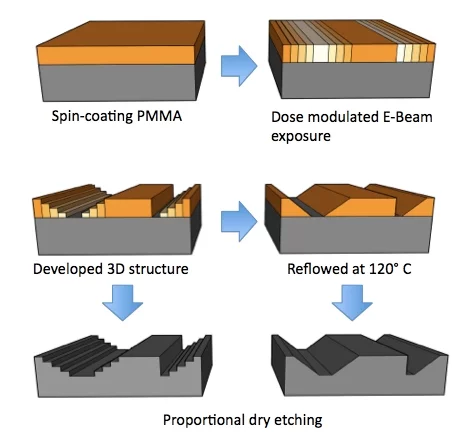

Selective thermal reflow During exposure, both the etch rate and the ability of the polymer to flow at a specific temperature are modified, enabling to etch different depths and to reflow these areas while those unexposed preserve their original shape. Therefore structures with both vertical and sloped sidewalls can be fabricated in the same resist. Further developments enable the fabrication of hybrid structures (surface nanostructures added before reflow) and combinations of processes (nanoimprint, exposure and reflow). This process is called TASTE (Thermally Assisted Selective Topography Equilibration). After pattern transfer these structures can be used as stamp for nanoimprint lithography and other replication techniques.

Microsteps fabricated by dose dependent electron beam exposure (grayscale lithography) reflowed on a hotplate at 120° C over two hours.

Combining nanoimprint lithography and a molecular weight selective thermal reflow for the generation of mixed 3D structures

J. Vac. Sci. Technol. B 29 06FC01 (2011)

A. Schleunitz, C.Spreu, M. Vogler, H. Atasoy, H.Schift

Selective profile transformation of electron-beam exposed multilevel resist structures based on a molecular weight dependent thermal reflow

A. Schleunitz, V. Guzenko, A. Schander, M. Vogler, H. Schift

J. Vac. Sci. Technol. B 29, 06F302 (2011)

Fabrication of 3D nanoimprint stamps with continuous reliefs using dose-modulated electron beam lithography and thermal reflow

A. Schleunitz and H. Schift

J. Micromech. Microeng. 20 095002 (2010)

J. Vac. Sci. Technol. B 29 06FC01 (2011)

A. Schleunitz, C.Spreu, M. Vogler, H. Atasoy, H.Schift

Selective profile transformation of electron-beam exposed multilevel resist structures based on a molecular weight dependent thermal reflow

A. Schleunitz, V. Guzenko, A. Schander, M. Vogler, H. Schift

J. Vac. Sci. Technol. B 29, 06F302 (2011)

Fabrication of 3D nanoimprint stamps with continuous reliefs using dose-modulated electron beam lithography and thermal reflow

A. Schleunitz and H. Schift

J. Micromech. Microeng. 20 095002 (2010)