A new material for energy-efficient data storage reaches computer operating temperature

Multiferroics are considered miraculous materials for future data storage – as long as their special properties can be preserved at computer operating temperatures. This task has now been accomplished by researchers at the Paul Scherrer Institute PSI, with colleagues from Institut Laue-Langevin ILL in Grenoble. With this, they have taken these materials one step closer to practical applications. The use of multiferroics holds promise for more energy-efficient computers because an electric field would suffice for magnetic data storage. To produce this, much less power and cooling are required than with conventional magnetic storage. Multiferroics combine magnetic and electrical properties to form a material that is extremely rare. Most such materials only exhibit these two properties at temperatures well below the freezing point. In order to keep the magnetic properties stable even at one hundred degrees, the researchers have employed a trick. They used atoms smaller than those employed in previous investigations, making the material more compact. This was enough to make its structure resistant to heat and preserve its crucial magnetic properties. The researchers published their results today in the journal Science Advances.

Computers often run continuously, consuming many kilowatts hour of electricity per year. Most of them are used for data storage. The data are written onto hard disks as magnetic bits in a 0 or 1 state, a process which requires a continuous reversal of polarity from plus to minus and vice versa. This magnetic pole reversal consumes a lot of energy, and leads to severe heat release. That is why computers have to be cooled intensively while they are operating. This requires a lot of electricity, high costs and is not environmentally friendly. Scientists have for a long time been searching for a material which eliminates this disadvantage of conventional magnetic data storage.

For some years, the so-called magneto-electric multiferroics have attracted the interest of researchers as a possible alternative. With these materials, the necessary magnetic functionality is achievable by applying an electrical instead of a magnetic field, because these two physical properties are coupled together in the material. This state usually occurs at very low temperatures, typically below minus 173 degrees Celsius, and is lost again at everyday temperatures.

Two years ago, a working group at PSI succeeded in shifting the temperature limit up to 37 degrees Celsius. This was a big step forward, but still was not enough to think about using it in laptops and other strongly heated data storage systems. Now, PSI researchers Marisa Medarde and Tian Shang have succeeded in stabilizing a magneto-electric, multiferroic material that retains the required magnetic properties even at 100 degrees Celsius. This temperature is more than 60 degrees Celsius higher than in the past,

Medarde says delightedly. Although a lot of further research is still needed, we are now a bit closer to a possible use of these materials in computers.

Two in one

The relatively new class of magneto-electric multiferroics includes various mixtures of chemical elements. These have one thing in common: they simultaneously contain small magnets and a combination of positive and negative electrical charges, the so-called electric dipoles. Electrical dipoles can usually be influenced by applying an electric field and small magnets by applying a magnetic field. For a multiferroic material, an electric field is sufficient for both. In practice, electric fields are much easier and cheaper to produce. They consume much less electricity. This is what makes magneto-electric multiferroics so interesting from an economic perspective. But how can one achieve the impossible?

In his laboratory at PSI, the physicist Shang shows different grey, white and yellow crystal powders, which he heats up in a laboratory oven to prepare the multiferroic materials for his experiments: Here, we use barium, copper, iron and rare earths, and we heat them up to over 1,100 degrees Celsius for two days. Then we slowly cool the powders down to room temperature, press them into pellets, and then heat them up again for 50 hours. They are then abruptly quenched in liquid nitrogen.

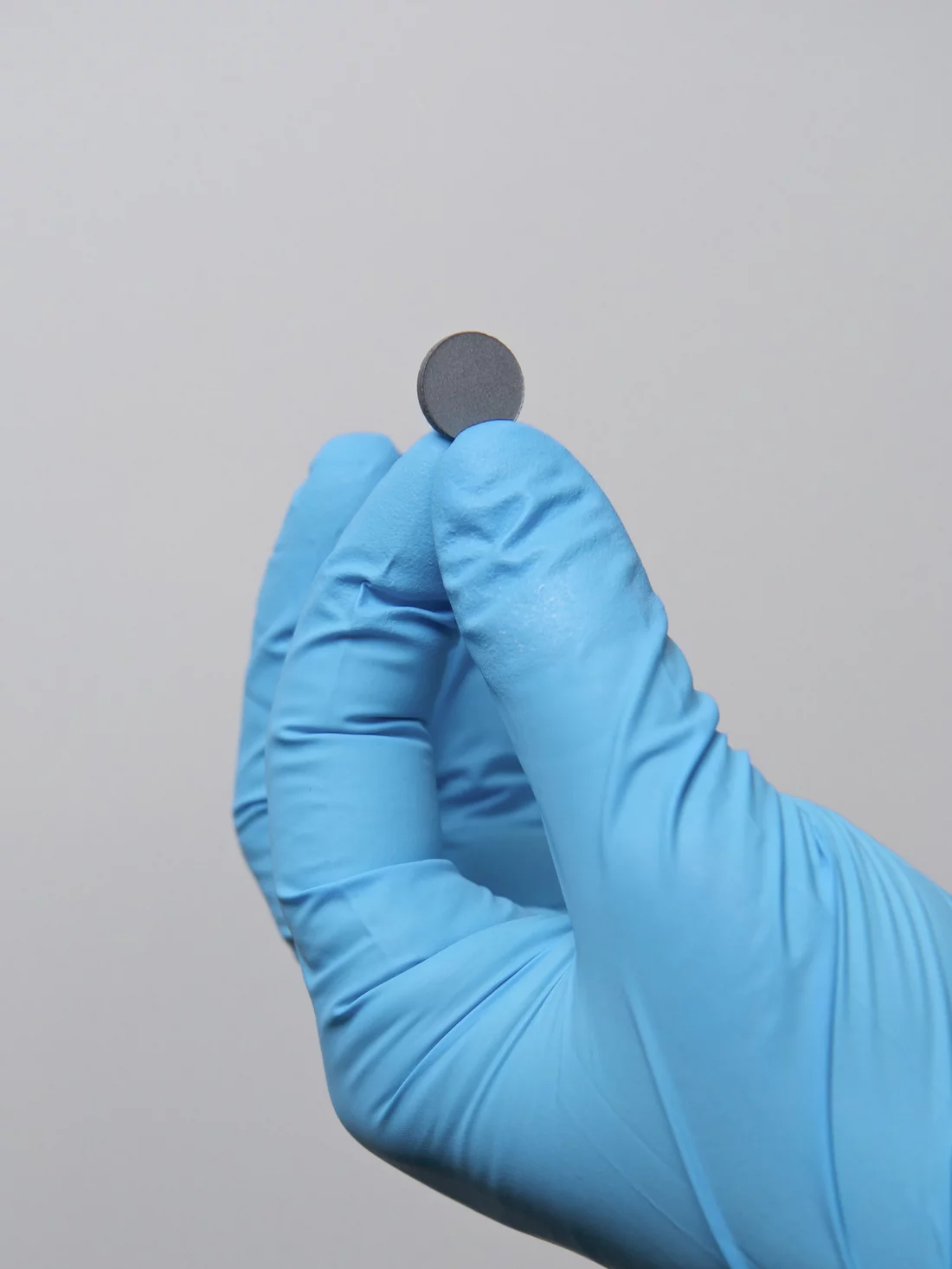

The dull grey material in the pellet that results from this procedure is a so-called layered copper-iron perovskite, a crystal. It is small enough to fit on a fingertip and at first sight does not seem very spectacular.

Frustrated magnets

The special features of the material are found on the non-visible level of the atoms, more precisely: in its crystal lattice structure. This can be pictured as consisting of several stacked lattice cages with barium and yttrium atoms at their corners. Inside the cages, small magnets made of copper and iron are located. Electromagnetic forces act between the individual magnets, determining their relative orientation. Normally, two magnets are aligned parallel or opposite to each other. But it can also happen that the magnetic forces act from very different directions. Then the magnets oscillate like little compass needles. The technical term for such a material is a frustrated magnet. In order to avoid this unstable state while preserving the magnetism, the copper-iron magnets arrange into a spiral. Enlarged, this looks like many superimposed compass needles, each subsequent one twisted by a small angle. This spiral arrangement can cause electrical polarisation and thus be responsible for the ferroelectric properties in the material,

explains Medarde.

Thus, when the magnets are spirally arranged, they induce electric dipoles in the lattice and the material gets both coupled properties – electrical and magnetic. At normal temperatures, the compass needles lose their helical arrangement, which also makes the coupled multiferroic properties disappear. The fact that the magnetic spirals in the material can be frozen

by very rapid cooling had already been shown Medarde and her group in an earlier work. In their latest investigation, Medarde and Shang have now fine-tuned the multiferroic crystal lattice. With microscopically small adjustments, they have succeeded in raising its temperature stability up to 100 degrees Celsius.

Proximity creates strength

Additionally to cooling the material extremely fast, Shang used a trick which chemists have known about for a long time: he simply reduced the distances between some atoms in the crystal lattice, bringing them closer to each other. As a result of the new, more compact design, the electromagnetic forces in the crystal changed in such a way that the spiral structure of the copper-iron magnets remained stable even at higher temperatures.

Shang achieved this by replacing some barium atoms in the crystal lattice with the smaller atoms of the element strontium. He added the strontium during the production of the material in the reaction furnace before finally cooling the material down again in the established way.

Next, the physicist wanted to know if the combination of the two methods had really had the desired effect. Shang studied the grey-black material using various measurement methods, including investigations at the Swiss Spallation Neutron Source SINQ, a large research facility at PSI. With the help of special instruments, he succeeded in identifying the fingerprint of the magnetic spirals. Of particular importance to the researcher was an instrument with the complicated name of a neutron diffractometer. With this device, which Shang used at both SINQ and the Institut Laue-Langevin ILL in Grenoble, he found out where the atoms are located in the crystal lattice and how far apart they are from each other.

The effect of rapid material cooling plus that of decreasing the distance between the atoms sum up together. The stability range of the magnetic spiral is now much higher than before,

said Shang. He has thus reached the temperature range needed for use in computers. However, according to the physicists, it will take a while for the material to actually be used for storing data in the future. For this, it will also have to perform in thin-film layers, where much less material is used. Medarde and Shang are already working on this. And they are attempting to squeeze the perovskite crystal even further by incorporating atoms that are even smaller than strontium. If both strategies are successful, there is good a chance that the multiferroic material will one day be the basis for revolutionising data storage technology.

Text: Sabine Goldhahn

About PSI

The Paul Scherrer Institute PSI develops, builds and operates large, complex research facilities and makes them available to the national and international research community. The institute's own key research priorities are in the fields of matter and materials, energy and environment and human health. PSI is committed to the training of future generations. Therefore about one quarter of our staff are post-docs, post-graduates or apprentices. Altogether PSI employs 2100 people, thus being the largest research institute in Switzerland. The annual budget amounts to approximately CHF 390 million. PSI is part of the ETH Domain, with the other members being the two Swiss Federal Institutes of Technology, ETH Zurich and EPFL Lausanne, as well as Eawag (Swiss Federal Institute of Aquatic Science and Technology), Empa (Swiss Federal Laboratories for Materials Science and Technology) and WSL (Swiss Federal Institute for Forest, Snow and Landscape Research).

(Last updated in May 2018)

Contact

Dr. Tian ShangLaboratory for Multiscale Materials Experiments and Swiss Light Source SLS

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 56 65

E-Mail: tian.shang@psi.ch

Dr. Marisa Medarde

Laboratory for Multiscale Materials Experiments

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 32 83

E-Mail: marisa.medarde@psi.ch

Original Publication

Design of magnetic spirals in layered perovskites: Extending the stability range far beyond room temperatureT. Shang, E. Canévet, M. Morin, D. Sheptyakov, M. T. Fernández-Díaz, E. Pomjakushina, and M. Medarde

Science Advances 4, eaau6386 (2018), 26 Oktober 2018 (online)

DOI: 10.1126/sciadv.aau6386