With its globally unique research infrastructure, PSI offers unrivalled opportunities for cutting-edge national and international research.

The main areas of research at PSI

Recent highlights from our research

Pollutants often originate in the air

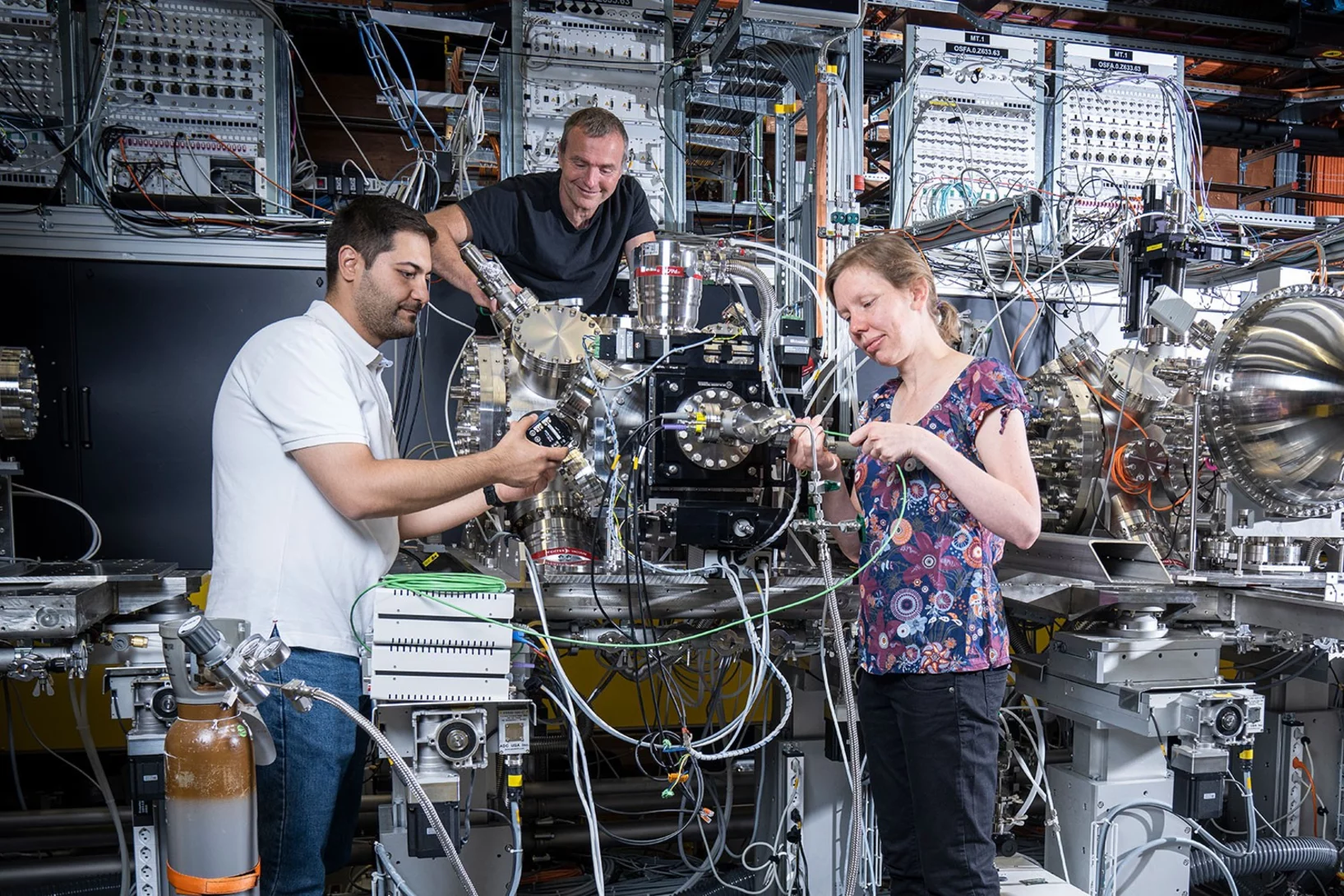

In the CLOUD experiment at CERN, PSI researchers have measured with unprecedented precision how harmful organic air pollutants are formed and dispersed.

A superlative milestone

PSI spin-off Araris Biotech AG achieves valuation at unicorn-level!

How botox enters our cells

Researchers at PSI have identified structural changes of the bacterial neurotoxin botox that are important for its uptake into nerve cells. This finding could allow a more targeted use of botox in medicine.

Interested in doing research at PSI? Do you want to use our infrastructure for cutting-edge research?

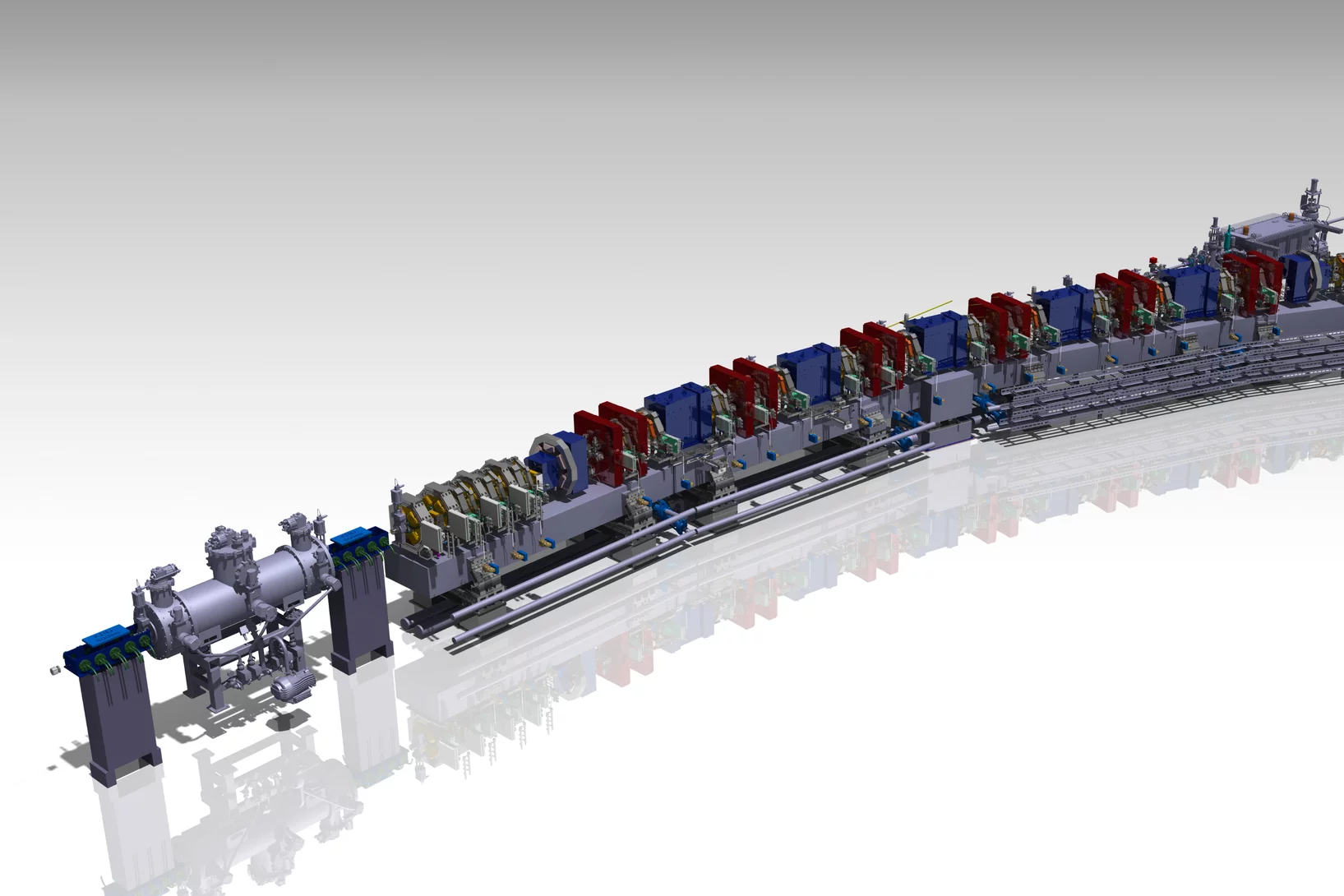

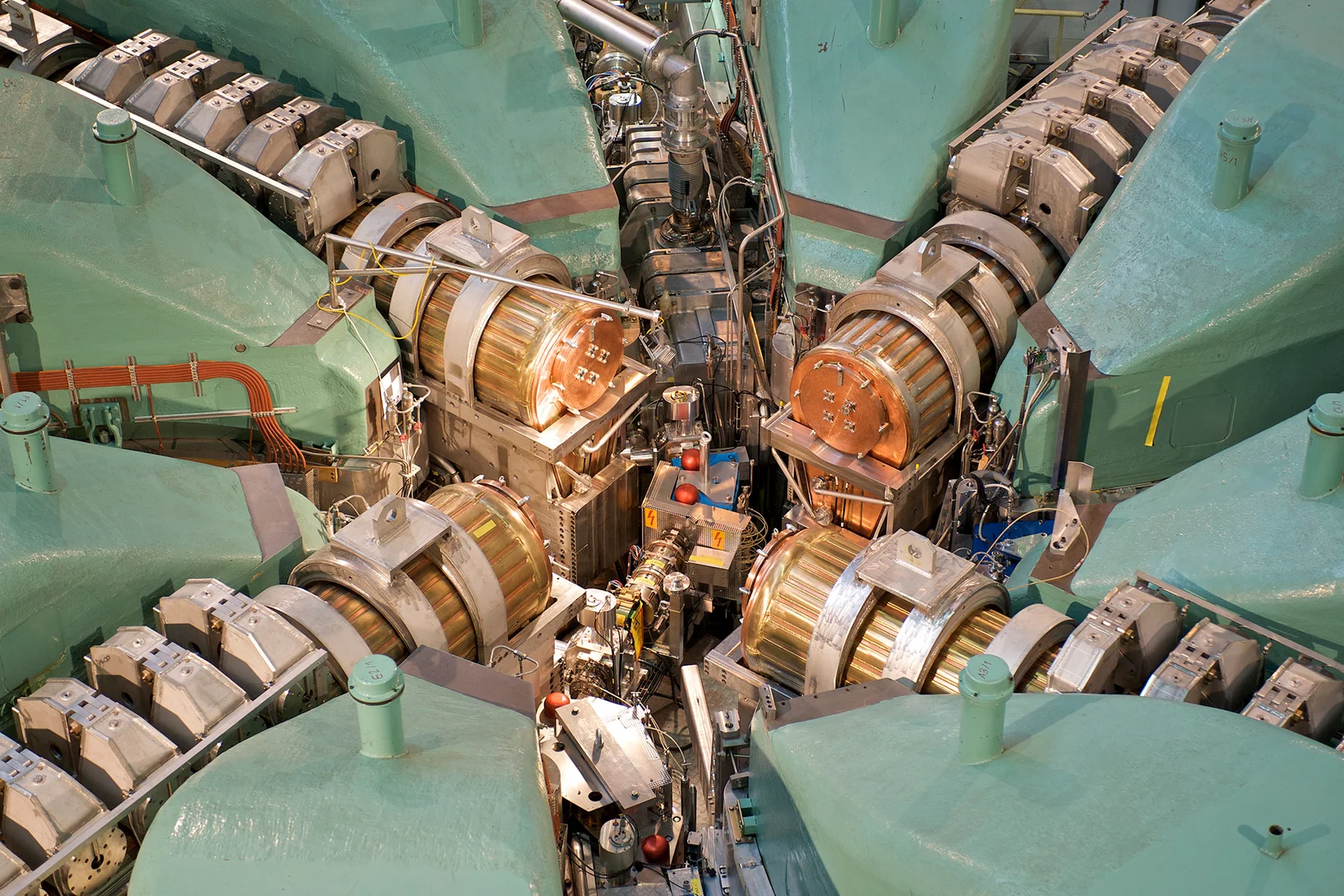

Find out more about our large-scale research facilities and other research centres.

Research Centers & Labs

Our research and service centres conduct internationally recognised cutting-edge research in the natural and engineering sciences and make highly complex large research facilities available to science and industry for their own research projects.

Scientific Highlights from our Centers

Anomalous Hall Effect due to Magnetic Fluctuations in a Ferromagnetic Weyl Semimetal

The anomalous Hall effect (AHE) has emerged as a key indicator of time-reversal symmetry breaking (TRSB) and topological features in electronic band structures. Absent of a magnetic field, the AHE requires spontaneous TRSB but has proven hard to probe due to averaging over domains. The anomalous component of the Hall effect is thus frequently derived from extrapolating the magnetic field dependence of the Hall response. We show ....

Rhodium recovery from acidic wastewater using radiografted chelating adsorbents

Platinum group metals (PGMs), particularly rhodium (Rh), are rare and vital for industrial applications, with Rh being scarcer (≈ 20 t/y) than platinum (Pt) and palladium (Pd). Its high cost and limited supply emphasize the need for efficient recovery from industrial waste. New radiografted chelating adsorbents, created through irradiation, offer a sustainable, cost-effective alternative to existing extraction methods. They exhibit high efficiency, selectivity, and reusability, making them ideal for recovering and recycling Rh from industrial wastewater.

Two Characteristic Contributions to the Superconducting State of 2H-NbSe2

Multiband superconductivity arises when multiple electronic bands contribute to the formation of the superconducting state, allowing distinct pairing interactions and gap structures. Here, we present field- and temperature-dependent data ...