In nuclear reactors, water is dissociated at the surface of the hot fuel elements, thereby producing hydrogen. This hydrogen can penetrate the fuel cladding surrounding the actual fuel and weaken it mechanically. Researchers from the Paul Scherrer Institute (PSI) have been using neutrons and synchrotron radiation to study how the hydrogen gets into the cladding tube and what impact it can have once inside.

The fuel rods in a nuclear reactor have a cladding tube that surrounds the nuclear fuel, thus forming an initial barrier to prevent radioactivity from escaping. The cladding tube consists of a zirconium alloy, a mechanically durable, corrosion-resistant material that only melts at very high temperatures. During operation, however, the cladding tube can weaken mechanically through the absorption of hydrogen, which compromises its protective function. Researchers from the Paul Scherrer Institute (PSI) have thus been investigating the hydrogen absorption mechanism and its impact on the cladding tube.

Zirconium alloys have already been used as a cladding tube material to protect the fuel in nuclear reactor fuel rods for decades. And the hydrogen problem was recognised from the outset. Consequently, there were already considerations early on as to how a possible weakening of the cladding tube through the absorption of hydrogen could be tackled. These included manufacturing methods designed to influence the spread and orientation of the hydrogen and its chemical compounds through the specific production of fine structures (texture) in the cladding tube. After all, it is advantageous if the fragile hydrogen compounds are distributed along the extent of the cladding tube instead of in a radial direction as this renders a malfunction under pressure less likely.

How hydrogen enters the cladding tube

The fuel rods in a reactor are bundled in fuel elements which are packed in water, which has several functions: the water serves as a moderator to slow down the neutrons to the speed necessary for nuclear fission, a carrier medium for the energy released during fission, which is ultimately converted into electricity, and a cooling agent for the fuel elements. At the high temperatures and pressure that prevail in the reactor, the water is broken down into hydrogen and oxygen on the exterior of the fuel rods. The oxygen oxidises the exterior wall while the hydrogen is partly able to move through this thin oxide coating and into the cladding tube. Not all zirconium alloys absorb the same amount of hydrogen. The Zircaloy-2 alloy used in boiling water reactors (e.g. Nuclear Power Plants Leibstadt and Mühleberg) is more sensitive than the usual Zircaloy-4 alloy for pressurised water reactors (e.g. Nuclear Power Plants Beznau and Gösgen). It would appear that nickel precipitations present in Zircaloy-2 but not Zircaloy-4 facilitate hydrogen absorption. PSI researchers are currently testing this hypothesis with the aid of synchrotron radiation from the Swiss Light Source (SLS), using x-ray techniques on irradiated cladding tubes for the first time to clarify the crystal structure and chemical environment of the nickel precipitations at the interface between the metal and oxide layer.

What is the effect of hydrogen in the cladding tube

The proportion of hydrogen in the cladding tube’s overall mass is low: only around a few hundred millionths (a typical value is around 100 mg of hydrogen per kilogram of alloy). However, this hydrogen can seriously diminish the mechanical stability of the cladding tube. The dissolved hydrogen (i.e. not chemically bound to the alloy) makes the cladding tube material more susceptible to plastic deformation at high temperatures. If the hydrogen concentration in the cladding tube becomes too high, it is no longer able to remain in dissolved form and precipitates as hydrides – hydrogen compounds with the alloying elements. At 300 degrees Celsius, a typical operating temperature in nuclear reactors, the hydrogen precipitates from a concentration of around 120 millionths. At room temperature, however, the entire hydrogen content is present in the form of hydrides.

Hydrides render the cladding tube more fragile. Moreover, an existing crack can propagate when brittle hydrides in front of it fail. These processes not only take place while the reactor is in operation, but also after the used fuel elements have been discharged, namely in the temporary storage phase to their transportation into a deep repository. The hydrogen problem is so important for nuclear safety that the American supervisory body is already considering making the hydrogen content one of the main criteria in the definition of the permissible service life of fuel elements.

Displaying hydrogen distribution with neutrons

Researchers therefore want to understand how the hydrogen spreads in the cladding tube once inside, which is important as the distribution and orientation of dissolved hydrogen and hydrides co-determine the extent of the potential mechanical damage. So far, tests have revealed that the hydrogen is inclined to diffuse towards the tip of existing cracks, where it usually forms hydrides quickly. However, there is no logical explanation for this. Some scientists presume that the diffusion follows a gradient of the local hydrogen concentration which is a consequence of its precipitation (according to this theory, the hydrogen moves from areas with a high concentration to those with a low concentration). Others believe that the driving force behind the diffusion is differences in stress. Accordingly, the hydrogen diffuses from places with low local stress to those with high stress.

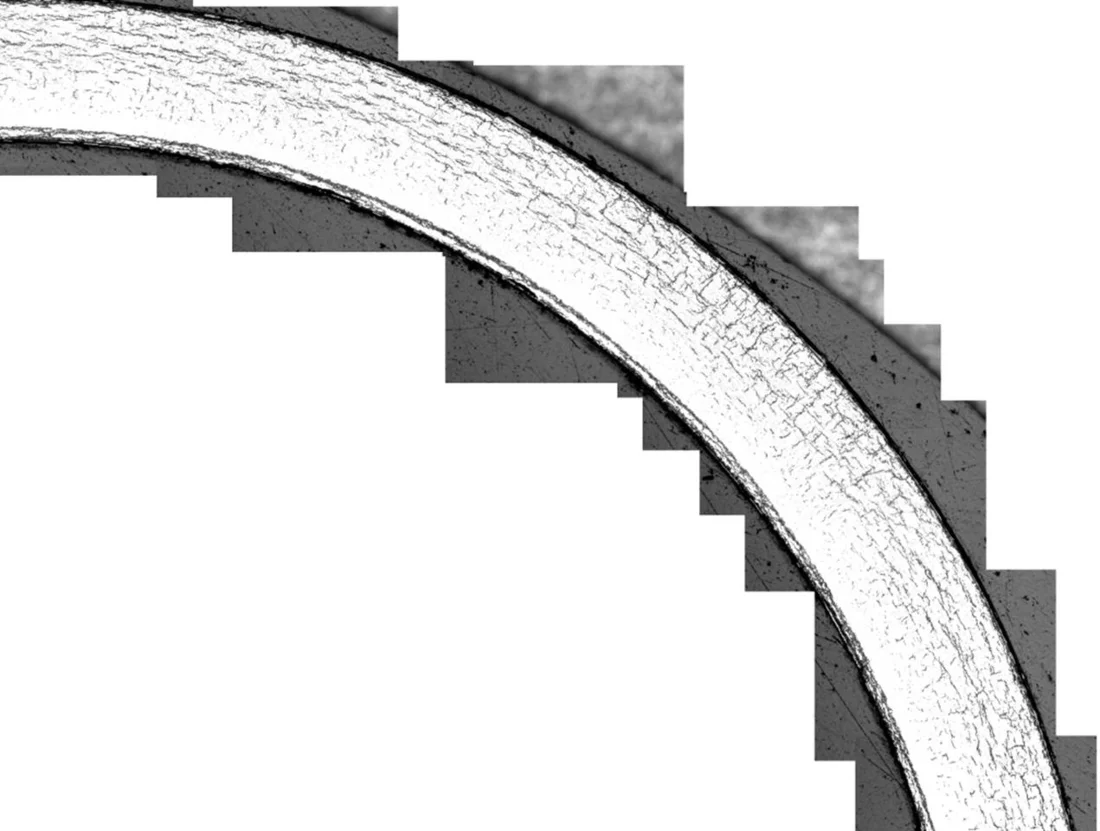

Based on measurements on the PSI’s neutron source SINQ, researchers from Johannes Bertsch’s team at the Laboratory for Nuclear Materials have now found evidence that it is in fact differences in stress that control the diffusion of hydrogen. The researchers took advantage of the fact that, unlike zirconium, hydrogen scatters neutrons extremely heavily. By shining neutrons onto cladding-tube material, the hydrogen diffusion could thus be displayed in situ. “It’s the first time that someone has used neutron radiography in a cladding tube under mechanical stress,” explains Bertsch. “This was the only way we could display the link between stress gradients and hydrogen diffusion. The next step will be to quantify this connection, i.e. find out how exactly the diffusion speed depends on the scale of the stress gradients.”

Text: Paul Scherrer Institute/Leonid Leiva

Additional information

Laboratory of nuclear materialsContact

Dr. Johannes Bertsch, Laboratory of nuclear materials, Paul Scherrer Institute,Telephone: +41 56 310 41 73, E-Mail: johannes.bertsch@psi.ch