The manipulation and examination of irradiated and therefore radioactive objects, be they from nuclear power plants or research facilities, requires strict safety measures. Tests can only be conducted in so-called “hot cells”, where the radioactivity is hermetically enclosed and shielded behind concrete and lead walls up to 1 metre thick to protect the employees and prevent the environment from becoming contaminated.

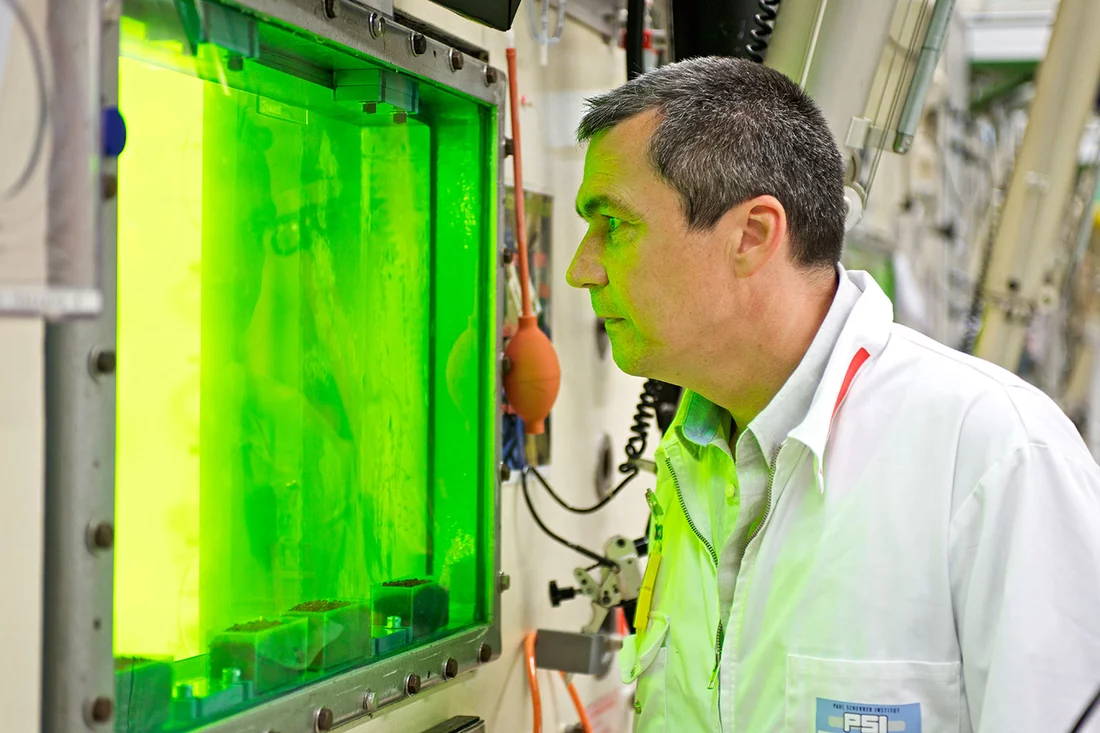

In the hot cells of the Paul Scherre Institute PSI hot lab, burnt fuel rods from Swiss nuclear power plants are studied from a material science perspective. Effects such as the potential embrittlement and oxidation of the fuel rod cladding, visible and geometrical alterations of the fuel rods as well as changes in the properties of the fuel itself, are intensively studied. The insights gained, help nuclear power plant operators to optimise the efficiency and safety of their plants. Besides this service, the hot lab is involved in several international research projects.

Neutron source of the future

A prime example of such an international study is the MEGAPIE project (Megawatt Pilot Experiment), which is jointly conducted by scientists from prestigious research laboratories from the EU, USA, Japan and Switzerland. PSI significantly contributes with several of its research units(*) to the success of the project. The main goals of MEGAPIE are the design, fabrication, licensing and safe operation of a high power liquid lead-bismuth target, as well as its subsequent examination and disposal. The target is designed to produce a high intensity neutron beam through the so-called spallation process. In this process, protons fired onto a target made of heavy metal smash the nuclei into pieces and knock neutrons out of these nuclei. The advantage of a liquid lead-bismuth target resides in the high neutron flux it can deliver. According to theoretical predictions, the neutron flux with such a target surpasses that of conventional water cooled solid targets, normally used at PSI, by roughly 80 percent. The higher neutron flux allows for a reduction of measurement times for a series of experiments, thus enabling scientists from many disciplines to obtain increased access to these highly demanded neutron sources.

For four months (August to December 2006), the liquid lead-bismuth target was bombarded by the world’s strongest proton beam from the high intensity proton accelerator ,HIPA, at PSI. The neutron yield obtained confirmed the theoretical predictions; this confirms the considerable progress that has been made with respect to the continuous operation of such a liquid metal target. For comparison, the average operation time of a standard solid spallation target at SINQ is two years.

Materials science investigations as the final stage of MEGAPIE

After the success of the four-month test operation of the liquid lead-bismuth target, it is now the materials scientists’ turn. They want to investigate the effects of material property changes due to the enormous radiation exposure. Until now, the initial studies have focused on the most strongly affected component: the steel window through which the proton beam entered the target. Two key findings were obtained through non-destructive testing: first, no cracks or even crack initiations were discovered in the steel; second, the thickness of the steel of the beam window remained practically unchanged at 2 millimetres– all this despite the intense proton irradiation to which the target was exposed.

Target dismantling and sample preparation in the hot lab

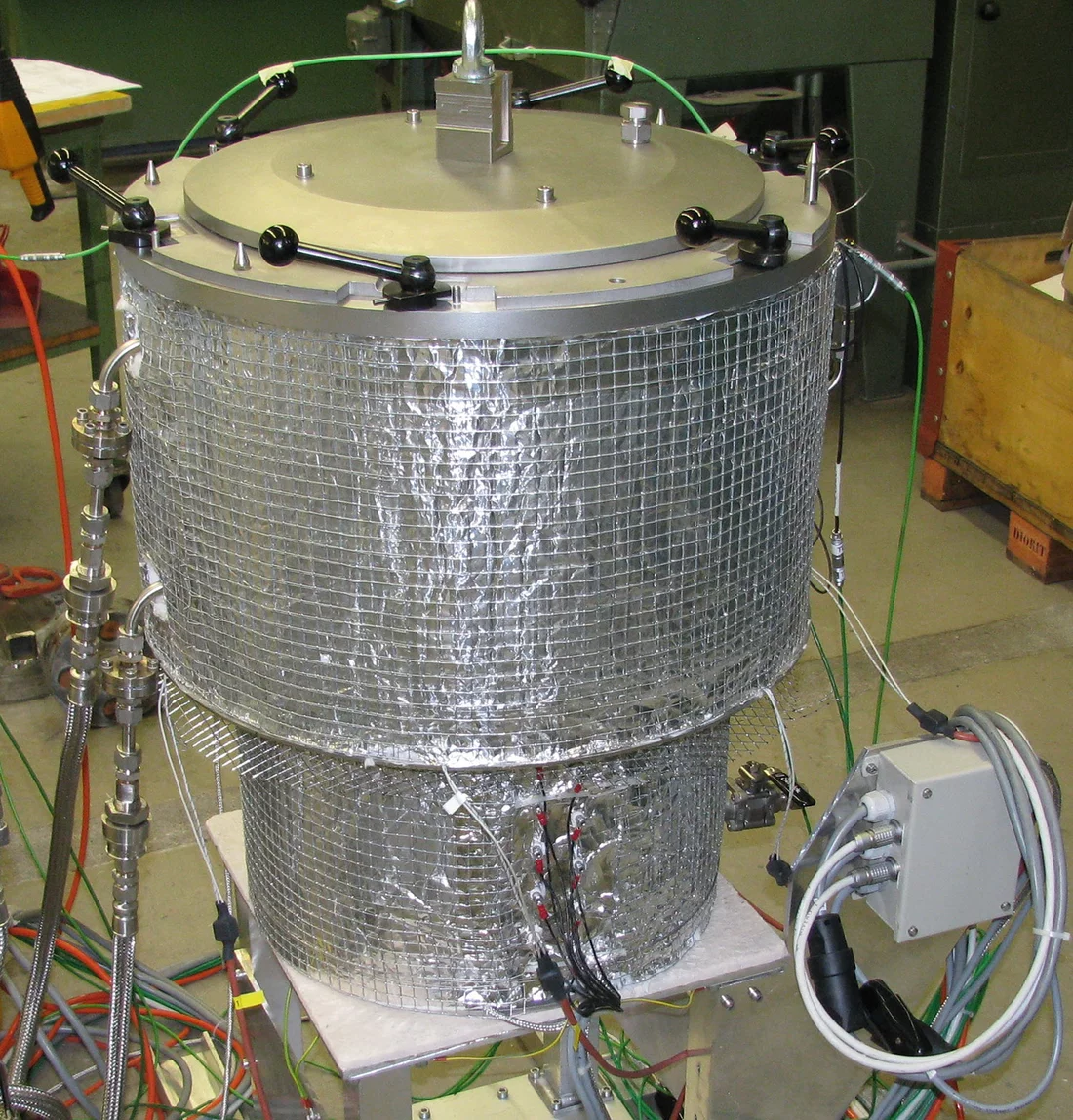

These first results have encouraged the scientists’ hopes for the robustness of the MEGAPIE target. However, for final and reliable results, further destructive tests on the target material have to be performed. In a first step, the target was cut into 21 pieces at ZWILAG, the interim storage facility for radioactive waste from the Swiss nuclear power plants. Then scientists, engineers and technicians from the PSI hot labhave prepared material samples for the destructive tests. The safe and precise manipulation of such a highly radioactive material is a task that, in Switzerland, can only be performed successfully at the PSI. First, the lead-bismuth mixture had to be melted, because the heavy metal mixture solidifies to below its melting point after operation. However, the lead-bismuth had to be carefully heated just above its melting point, as the scientists didn’t want to alter the status of the steel cladding by overheating it. Consequently, under the supervision of the MEGAPIE project leader Michael Wohlmuther, researchers from the target development group, the Engineering department and the Hotlab built a special furnace for this task.

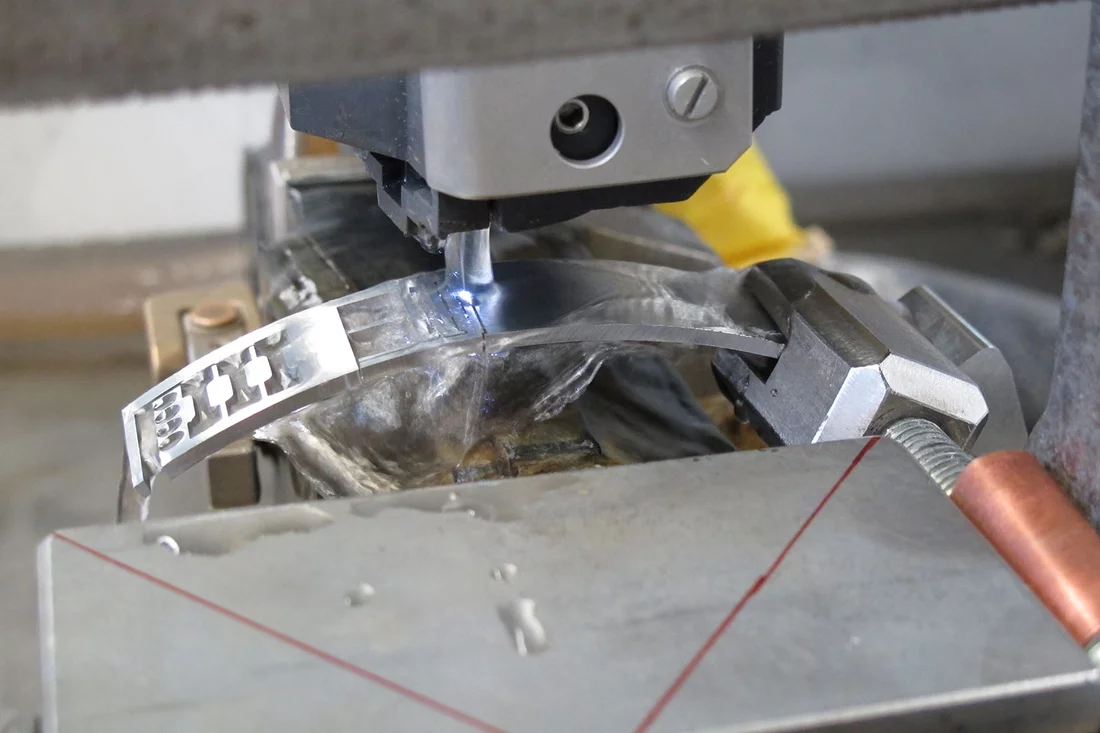

Once the liquid lead-bismuth had been removed, the target cladding had to be cut up with utmost care and attention. The saw blade of the milling machine made its way through the steel with a speed of only a few millimetres per minute. “ During cutting, the temperature of the target cladding needed to be kept below 200 degrees Celsius to maintain its integrity for the next round of tests,” explains Daniel Kuster, the group leader for hot cell experiments who coodinated the sample preparation and dismantling of the target at PSI’s Hotlab. Now that roughly 800 samples have been fabricated, the MEGAPIE target faces the final litmus test: in the coming months, its integrity after the fierce irradiation campaign is to be studied by bending and tensile tests of the samples by the partners involved in the project. Approximately 400 samples will remain at PSI, where they will be investigated by a team under the supervision of Yong Dai, a material scientist in the group. The remaining samples will be subjected to investigations by the international project partners from the EU, the USA and Japan. Final results are expected by the end of 2014.

Text: Leonid Leiva

(*)In addition to the Hotlab of the department of nuclear energy and safety, the following PSI units contribute to MEGAPIE: the Department Research with neutrons and muons, the Department Large research facilities and the Group Radwaste analytics (Department Biology and Chemistry).

High energy neutrons like those produced from the MEGAPIE target, are well suited for converting long-lived, highly radioactive substances produced as nuclear waste by nuclear power plants into shorter-lived or even stable elements (isotopes). Such a conversion (called transmutation) is for instance possible in so-called accelerator-driven systems (ADS). In ADS, the fission reactions are not self-sustaining like in ordinary nuclear power plants. Instead, the chain reaction is controlled by spallation neutrons produced in a liquid metal target, such as MEGAPIE, using an integrated proton accelerator. The synchronisation of the sub-critical reactor and the proton accelerator increases the complexity of the system compared to conventional nuclear reactors. Furthermore, a sufficiently strong neutron beam is required to transmute large quantities of used nuclear fuel. MEGAPIE should yield valuable data and experiences in this respect, even if, according to the experts, we are still far from realizing a usable and affordable transmutation technology.

Additional information

Webpages of the MEGAPIE projectWebpages of the PSI Hotlab

Contact

Dr. Michael Wohlmuther, MEGAPIE Project leader for PSI, Paul Scherrer Institute,Telefon: +41 56 310 30 52, E-Mail: michael.wohlmuther@psi.ch

Daniel Kuster, Head of the group Hot cell experiments, Paul Scherrer Institute,

Telephone: +41 56 310 27 58, E-mail: daniel.kuster@psi.ch