One important question regarding the planned transition to supplying energy without greenhouse gas emissions is: How can we store energy for times when wind turbines and photovoltaic systems are not supplying electricity? Researchers at the Paul Scherrer Institute and the start-up AlphaSYNT offer one possible answer. With a new approach to “power-to-methane” conversion, they are promoting a technology for storing energy in the form of methane gas that is ready for industrial use.

Let’s take the following imaginary scenario: It’s the year 2050. As part of a charity event, and at the urging of his fans around the world, Roger Federer, now 69 years old, ventures onto the court again to compete in a “friendly game” against his long-time rival Rafael Nadal. A global event that will be broadcast live from the St. Jakobshalle arena in Basel to domestic and international screens, as well as countless public venues throughout Switzerland. It’s a muggy Saturday afternoon in July, loads of drinks are being chilled, and air conditioners are running full blast. The sky is overcast, and there’s no wind.

The weather conditions are probably not ideal for Roger Federer, who is no longer quite so young, to engage in high-performance sport. The oppressive atmosphere could also cause problems for the viewers. In 2050 there will no longer be any nuclear power plants connected to the grid in Switzerland, and renewable energy sources such as wind and solar power will make a vital contribution to our electricity supply. But when the sun doesn’t shine and the wind doesn’t blow, the screens could go black and the biggest TV event of the year could be cancelled.

Granted, this scenario seems a bit contrived, but the underlying problem is red hot. Storing energy from renewable sources in a sensible way, so that it can be fed into the grid outside of peak production times, is a challenge that is being intensively investigated – including at PSI.

Use the existing infrastructure

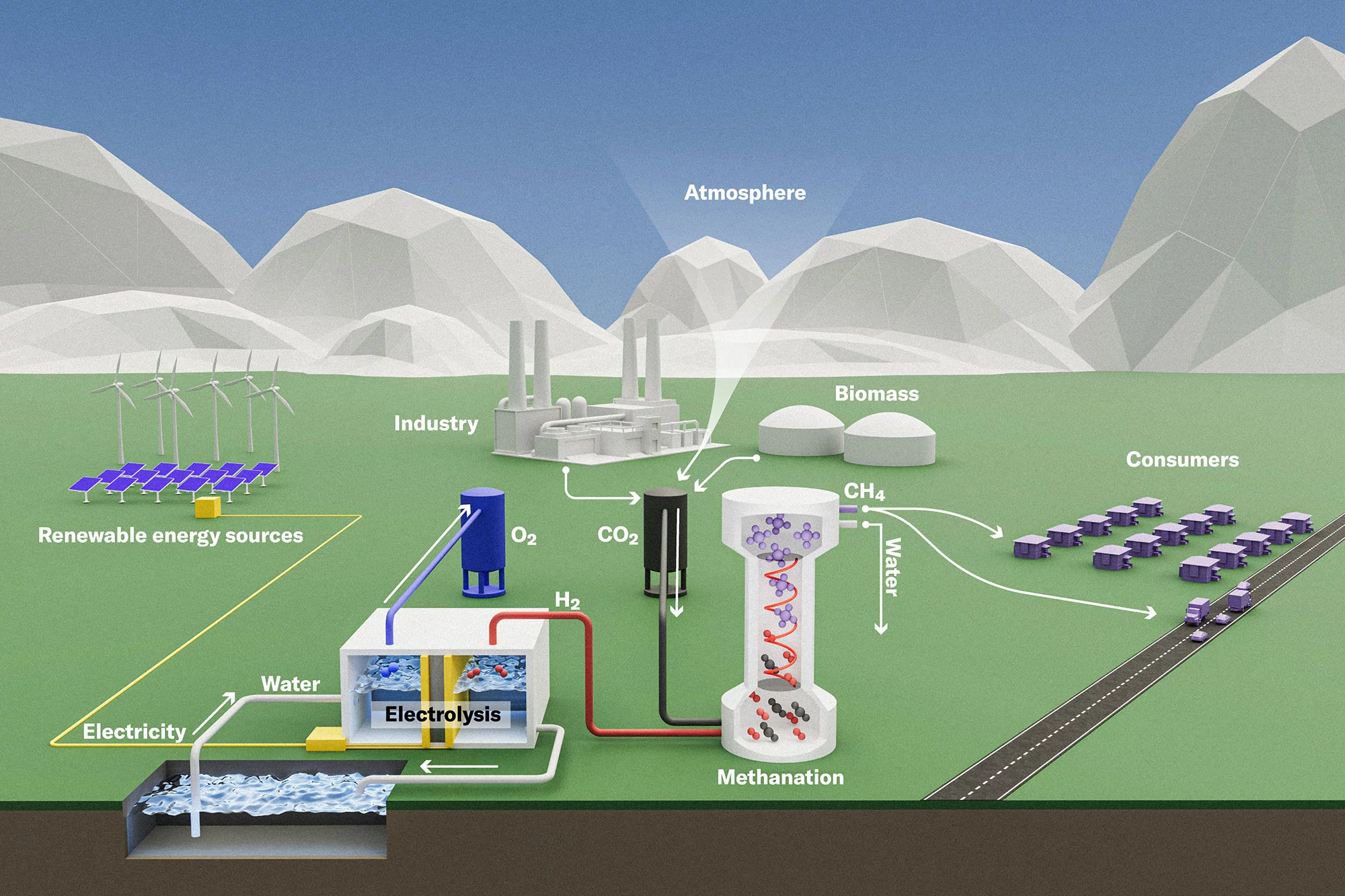

For almost ten years, the Laboratory for Bioenergy and Catalysis at PSI has been developing processes to cleanly and efficiently convert biomass from agricultural and forestry waste into gaseous or liquid combustibles or fuels. This concept, called powerto- gas, envisages using excess renewable electricity to produce hydrogen and, in a second step, converting it into synthetic natural gas.

The first step occurs through a process called water electrolysis, where water is split into hydrogen and oxygen. This converts the electrical energy into a chemical energy carrier, hydrogen.

“With the help of fuel cells, hydrogen can be converted back into electricity,” explains Tilman Schildhauer, scientific lead on methanation and industrial power-to-X at PSI. These cells are very powerful and clean. Because they do not require combustion, the only by-products are heat and water. “However, the production costs are very high. In addition, hydrogen is a light gas that requires an enormous storage volume. Switzerland still lacks the necessary infrastructure to use hydrogen sensibly.”

Methane is a different story. This colourless and odourless gas takes up only a third of the volume of hydrogen with the same energy content, and it can already be stored and distributed using the same infrastructure as natural gas. That’s why Tilman Schildhauer and his team are focusing on using the hydrogen obtained through electrolysis to synthesise methane in a second step.

From hydrogen and carbon to methane

Back in 1902, the French chemists Paul Sabatier and Jean-Baptiste Senderens discovered the reaction of carbon dioxide and hydrogen to form methane and water. Since this discovery, many different processes have been developed to make this reaction as efficient as possible. For their methanation process, researchers at PSI have developed a fluidised bed reactor, which contains fine nickel particles as a catalyst. When the carbon dioxide and hydrogen are fed in, the particles are swirled around and converted into a fluidised state by the upward flow – so the reaction is continuous.

Besides methane and water, this reaction also produces high temperatures. To maintain the process and achieve a high throughput, the mixture must be cooled down to the optimal reaction temperature. Tilman Schildhauer and his team have devised a special trick to resolve this: “We use a pipe system that allows oil to flow through our reactor. The oil absorbs the heat inside the reactor and releases it outside – just like a refrigerator,” Tilman Schildhauer explains. This construction, combined with the fluidisation of the particles, allows especially efficient cooling, resulting in an isothermal, compact and low-cost reactor.

This reactor can now be used, for example, in biogas plants. Biogas is produced by fermenting biomass such as liquid manure, plants, or sewage sludge, and consists of about two-thirds methane and one-third carbon dioxide. For this gas mixture to be used effectively in the gas network, it must have a certain level of purity – at least 96 percent methane content. “The gas mixture is fed into our fluidised bed reactor together with the hydrogen obtained, and the carbon dioxide reacts to form additional methane,” says Tilman Schildhauer.

The step from laboratory to industry

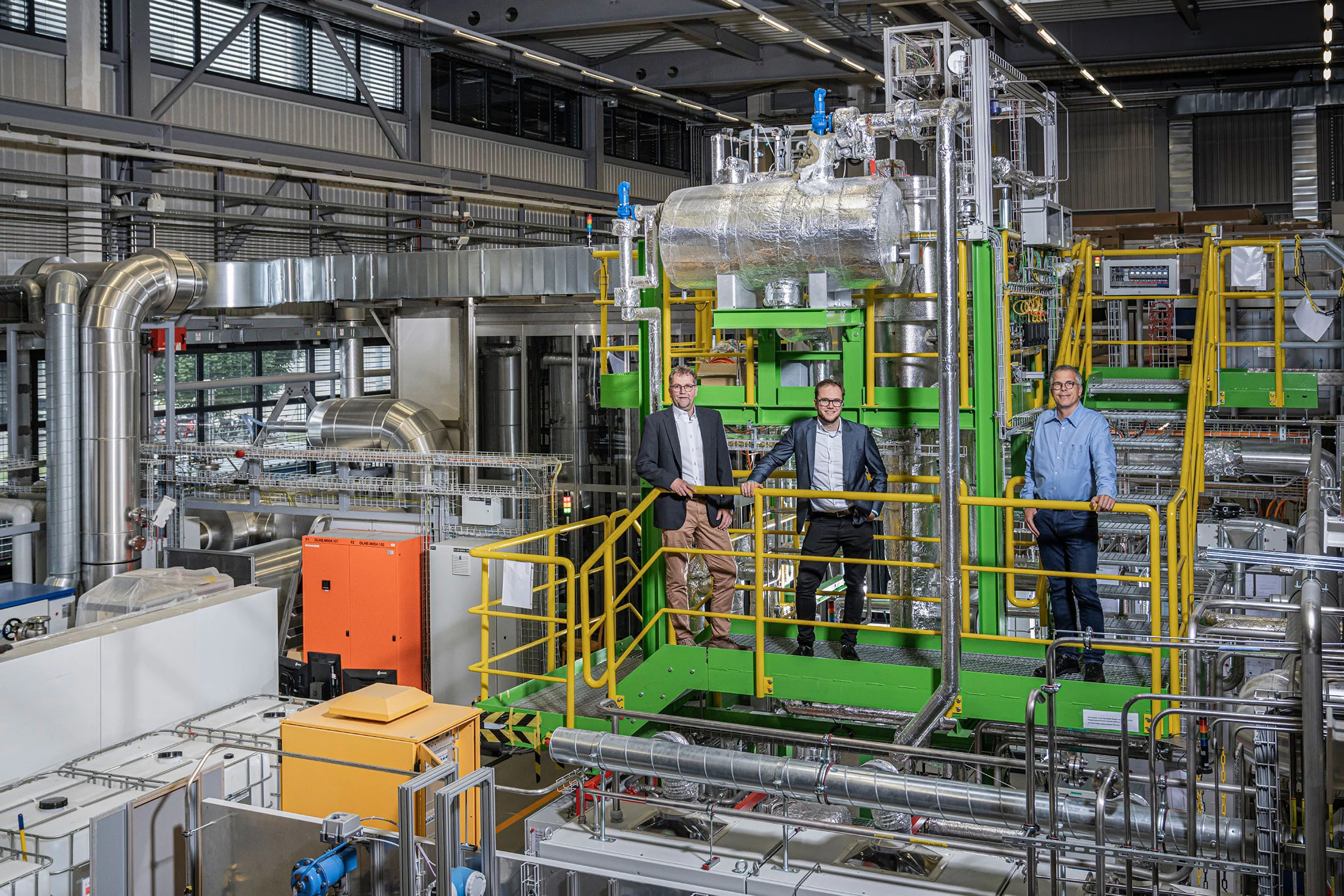

The technology works, and with GanyMeth a first pilot reactor was built and tested at PSI. The task now is to implement the methanation process in industry. To this end, PSI has joined forces with the start-up AlphaSYNT. Together they want to take the new approach to market, though not for private households – the technology is too complex for that. The main target market is larger energy suppliers that own biogas plants, which could profit from this technology.

AlphaSYNT was founded as a start-up in 2020 by Andreas Aeschimann (CEO) and Luca Schmidlin (CTO). A chance conversation during a coffee break at a measurement technology seminar grew into a strong partnership with a common goal. “Alpha stands for the beginning. We both wanted to be at the forefront, taking a chance and investing to help shape and advance the transformation of the energy system. Luca and I hit it off right away,” Andreas Aeschimann recalls. “The technology from PSI is ready to use. Thanks to our business and technical know-how, we can now achieve this goal.”

With the commercialisation of the methanation process developed at PSI, fossil gases should be successively replaced by renewable methane gas. “The flexible storage of surplus electricity from renewable sources in the summer will also help to stabilise the power grid,” explains Andreas Aeschimann.

Looking towards the future

It’s not only biogas plants that can benefit from partnership with AlphaSYNT and PSI. The technology works with carbon dioxide from any source. It could be captured directly from ambient air, for example, or could come from wastewater treatment plants, waste incineration plants, cement works, or plants with wood gasification. For the latter, AlphaSYNT and PSI were awarded a contract to construct a methanation plant in Portugal in May 2022.

The pilot reactor is part of PSI’s Energy System Integration Platform, ESI for short. Here PSI, in close collaboration with AlphaSYNT and other partners from research and industry, is looking into the technical and economic feasibility of different variants of power-to-gas technology.

So nothing should stand in the way of our fictitious future tennis match – it would all come down to the motivation of Roger Federer and his possible opponent, Rafael Nadal.

Text: Benjamin A. Senn

Copyright

PSI provides image and/or video material free of charge for media coverage of the content of the above text. Use of this material for other purposes is not permitted. This also includes the transfer of the image and video material into databases as well as sale by third parties.