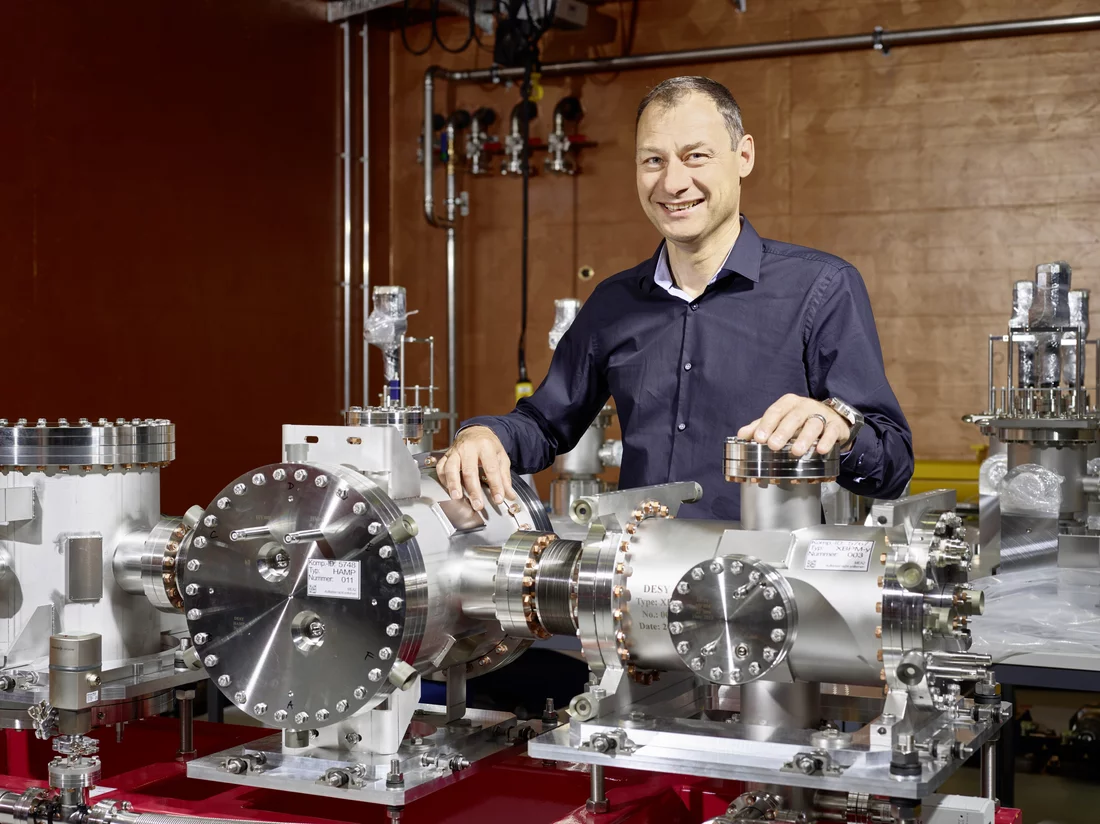

Interview with Luc Patthey

Luc Patthey is in charge of designing and implementing the beamlines for the X-ray free-electron laser SwissFEL. In this Interview, he explains the requirements the beamlines need to meet for the X-ray light pulses generated by SwissFEL to reach the experiments in an optimal form and what role collaborations play in the development of beamlines.

The X-ray free-electron laser SwissFEL is currently under construction. You're in charge of designing and implementing its beamlines. What is a beamline and what are they for?

SwissFEL will generate pulses of X-ray light that open up completely new research possibilities for us. These pulses are transported to the experiment via beamlines. In the process, they are deflected in the right direction by mirrors and moulded into the right form depending on the particular requirements of the experiment in question. For instance, you can focus them or vary their wavelengths within a pre-specified range. Every single one of the roughly 100 pulses of X-ray light produced by SwissFEL every second is different. Moreover, their properties are measured as accurately as possible for every single pulse to make sure they are just right for the experiments. And the time the X-ray light pulses arrive at the beamline is also recorded.

Why is it important to know when the X-ray light pulses reach the beamline?

You need this information for certain experiments, where a conventional laser activates the exact process that you want to study in a sample. A few femtoseconds later, an X-ray laser pulse X-rays it, which enables you to find out what has happened in the sample in the space of these femtoseconds. For instance, you can observe chemical reactions that were simply too rapid for previous study methods. Timing the two lasers with the necessary precision is an immense challenge. Just so you can imagine the temporal dimensions we're dealing with here: one femtosecond is the time the light takes to travel 0.0003 millimetres.

Do these high precision requirements only apply to the facility itself or the facility's building, too?

The building, too. Because of these timing demands, the temperature in the beam channel mustn't deviate from 24 degrees by more than 0.1 degrees. Even the slightest expansion or contraction in the material triggered by temperature fluctuations would throw off our "time management" and spoil our experiments.

If only the slightest material changes are a problem, doesn't this mean that the diagnostics or beam control with all their components also have a certain interference potential?

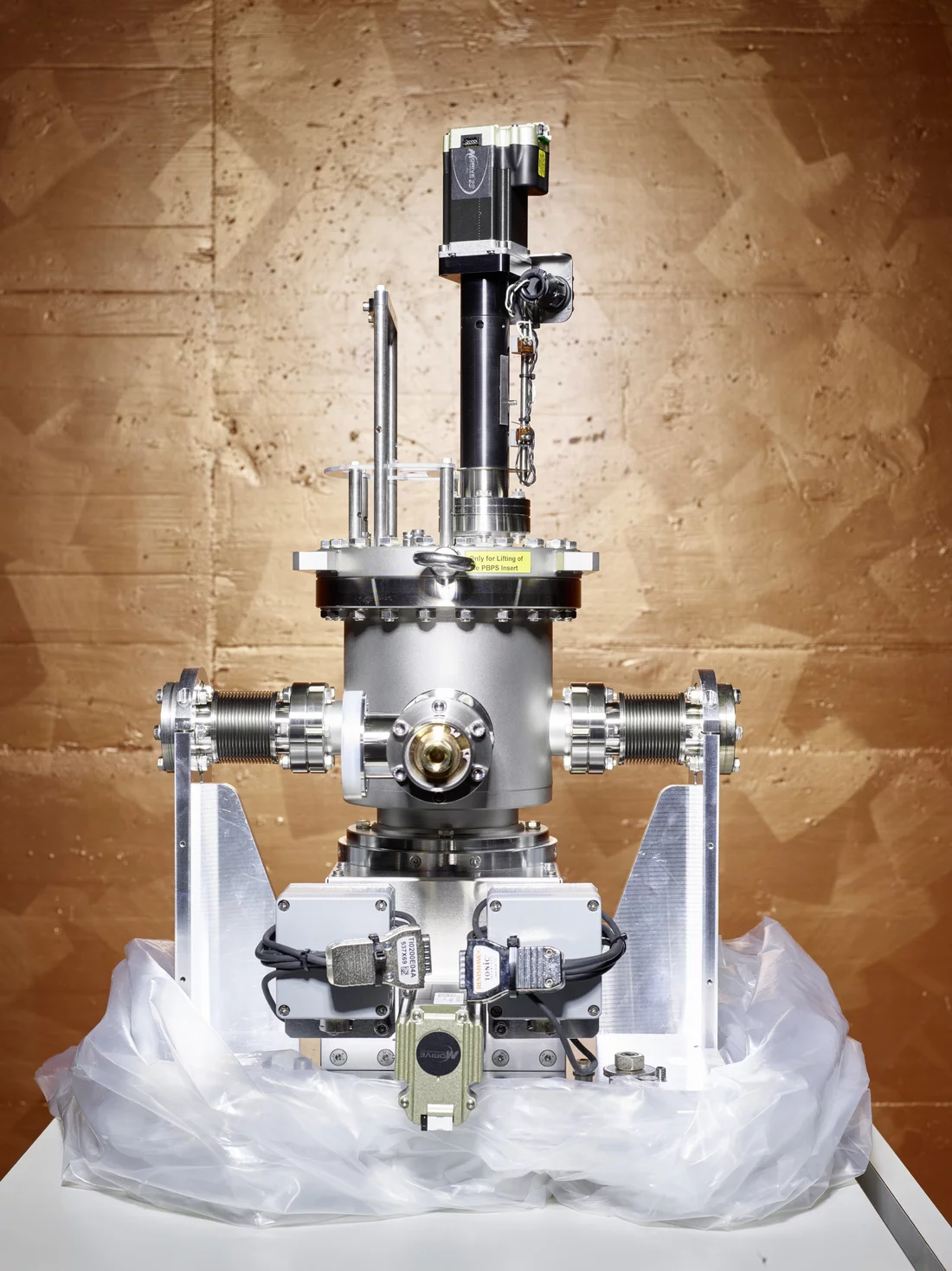

It's our job to make sure that nothing happens here. Under no circumstances must the quality and timing of the X-ray pulses be affected. You don’t notice the perfect beamline. You have to imagine it like a pair of spectacles: when you wear the right glasses, you don’t see the lenses. Naturally, that also means we have to build the components for the beamlines with extreme precision.

Just how precise do the components need to be?

Take the mirrors used to guide the X-ray pulses I mentioned earlier: they are around 80 centimetres long and throughout this length their surface is smooth to a precision of three nanometres. Just to illustrate what that means: imagine you were travelling from St. Gallen to Geneva and chose a route over the Matterhorn. If Switzerland were as flat as our mirror, you'd only have to scale a difference in altitude of three millimetres as opposed to the present 4,500 metres. You can imagine the demands that places on the production of the mirrors: they spend several months just being polished.

What with all these component requirements, how about their development: does PSI do it all itself here or are there collaborations?

Both. Of course, we boast an impressive amount of knowhow on site with our experts at PSI. But we also draw inspiration from other facilities to design the beamlines. The international exchange is lively and the mutual support vast: we cooperate with colleagues from the Deutsches Elektronen-Synchrotron (DESY), the X-ray laser European XFEL, the Japanese X-ray laser SACLA or the US X-ray laser LCLS. And we build other components here at PSI in collaboration with international or local companies.

SwissFEL is due to be launched at the end of 2016. Initially, it will emit one beamline, but a second is in the pipeline. Why do we need two beamlines?

SwissFEL will generate two kinds of X-ray light pulses - so-called "hard" pulses with a short wavelength and "soft" ones with a longer wavelength. This means that a wide variety of experiments can be conducted using the two SwissFEL beamlines, which enables us to accommodate the needs of researchers from Switzerland and abroad optimally.

Planning and constructing beamlines for a new, large research facility is not your everyday, run-of-the-mill task. What do you like most about your work?

Every beamline is unique and sometimes you enter uncharted territory while developing them. I love this aspect of my work. It was already clear that I enjoyed exploring new ground as a young boy: when my grandma's washing machine broke down, I took it apart and managed to fix it, without actually having a clue how it worked. And it went for years afterwards. I've never lost that joy of experimentation and discovery, which stands me in good stead now in realising the beamlines for SwissFEL.

Interview: Paul Scherrer Institute/Martina Gröschl