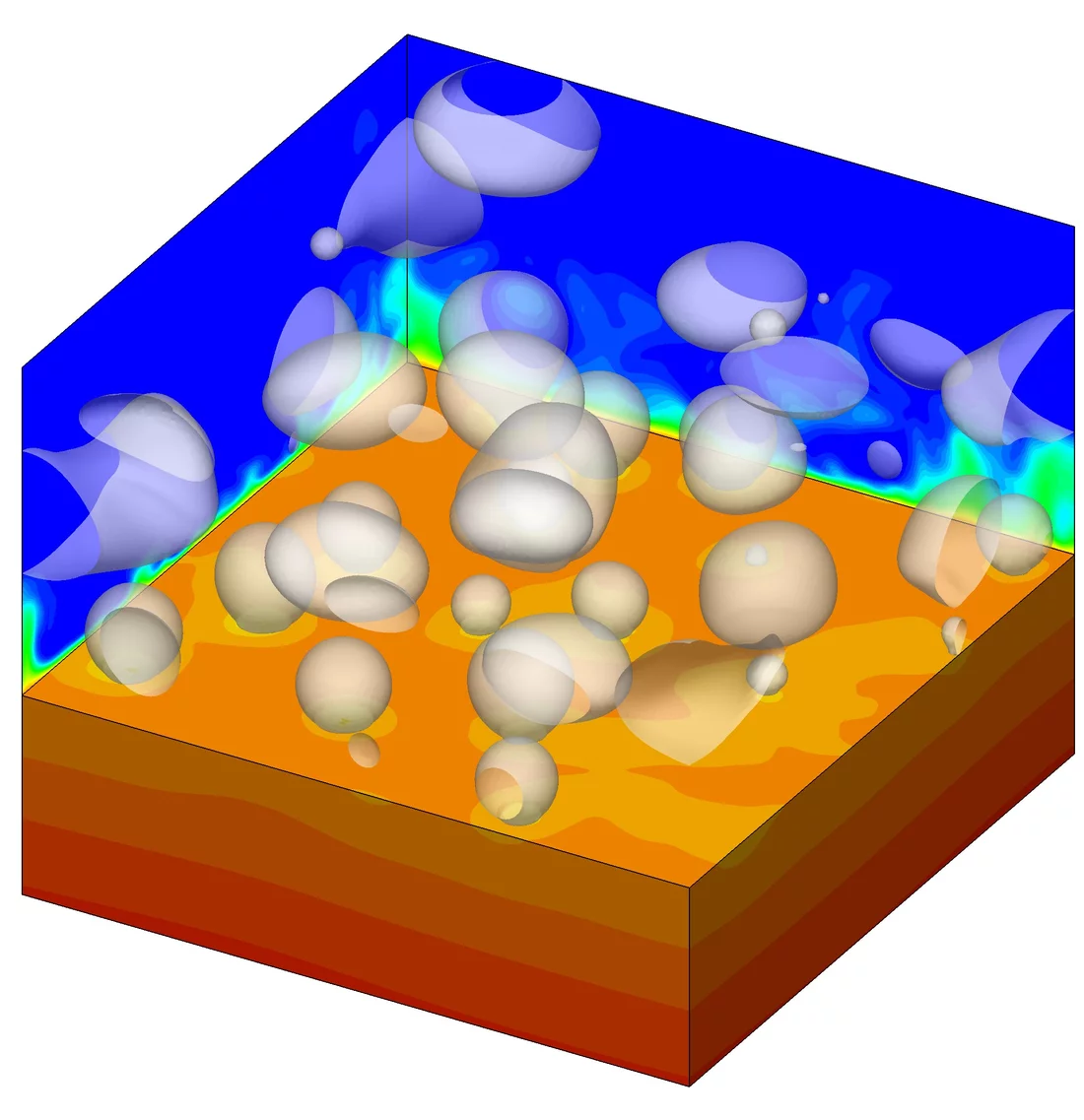

In most cases, electricity is produced when water is heated and transformed into vapour. Vapour bubbles in the water play a decisive role in this process by collecting in a layer at a heated wall. The denser the layer, the more efficiently the heat will be transferred to the water as soon as the bubbles detach themselves from the wall. However, it’s imperative that the vapour bubbles are prevented from forming a single, unbroken layer at the wall: on the one hand, vapour itself is not a good heat conductor and on the other, this could lead to an overheating of the wall. Using computer simulation, researchers at the Paul Scherrer Institute have succeeded in representing the behaviour of vapour bubbles – and in making their performance more calculable.

Yohei Sato’s computer screen shows a vapour bubble in far greater detail than can normally be seen by the naked eye. It shows a simulated bubble adhering to a heated wall and surrounded by water. By slowly bringing the water to a boil, the bubble grows and takes on a succession of different forms that resemble a dome, a knob handle and a balloon. At some stage, the bubble detaches itself and lurches upwards through the imaginary fluid.

The PSI researchers Sato and the head of his research team Bojan Niceno have put a lot of thought into this seemingly simple sequence of images representing the growth of a bubble. The mathematical formulae tracing the growth of a bubble have actually been known for some time. However, we had to turn them into a computer-digestible form,

says Sato. It’s hard to believe, but the physics behind the everyday process of producing bubbles by boiling water has never yet been reproduced with such accuracy at the computer.

Proper Boiling

PSI scientists take bubbles very seriously. About 85% of the world’s electricity is produced by heating water and turning it into vapour. The heating process involves the burning of fossil fuels such as coal, gas or oil. Nuclear power stations produce heat via fuel rods. The vapour then operates a generator, which in turn produces electricity. In these processes, vapour bubbles play a decisive role in ensuring that water is boiled efficiently.

If the bubbles start to cover the heated wall like a tightly woven grid, heat is transferred to the water more efficiently. This is because vapour bubbles grow by assimilating the vaporising water around them. At some stage, they break away from the wall and carry heat into remote water fields. These conditions, known in specialist circles as nucleate boiling

only occur when the temperature at the wall is slightly higher than the boiling point of water. If the temperature continues to rise, the rate of bubble production increases to the point at which a continuous, thin layer of steam is created at the hot wall. Because vapour is not a good heat conductor, heat no longer transfers as quickly to the water. As a result of this so-called film boiling, the wall either dries out or, in a worst-case scenario, burns through.

A Computer-generated Bubble Image

Hence, finding the right temperature is a balancing act: as many bubbles as possible need to be created without ever crossing the line into film boiling. This is why the researchers use the computer to calculate the growth and movement of bubbles in liquid as accurately as possible. This allows them to deduce the temperature at the wall at any time. A calculation method able to compute this data could be used to build safer and more efficient power stations

, says Niceno.

With this end in sight, Sato and Niceno worked meticulously as they began developing the computer programme PSI-BOIL: the programme divides a bubble and its environment into tiny cubes whose sides measure only a few thousandths of a millimetre. For every tiny cube, data is gathered on the temperature, the pressure, the aggregate state (fluid or gaseous) and the velocity of vapour and water currents in the vicinity of the bubble. Just simulating one single bubble is a challenge. Sato’s PC with its four core processors would have taken at least two years to compute the necessary data. So the researchers have taken recourse to the PSI’s very own Merlin: a computer which is actually a network of several hundred processor cores. Even using the combined capabilities of 128 Merlin processor cores, the simulation takes three weeks. On the other hand, the process it depicts takes no longer than five seconds.

Reality Correctly Imaged

PSI-BOIL has enabled the researchers to facilitate the calculation of nucleate boiling first for one single and then for several bubbles. In the simulations, the bubbles showed the same phases previously recorded in real experiments with video and infrared cameras. Even more important, the simulations delivered the correct temperature values for every point on the wall beneath the bubble. Researchers worldwide have been working on compiling such accurate simulations of nucleate boiling for decades

, says an evidently pleased Sato. By turning our attention to the all-important water level immediately below the bubble as well as focusing on the remaining boundary layer we were able to reach an important milestone

, adds Niceno.

This success is hard-won: the equivalent of eight-years of one individual’s working time has gone into research projects and industrial cooperation. There’s still a long way to go, however. As the scientists themselves explain: So far, we’ve only been able to capture processes taking place in motionless water. But most technical usage involves water flowing along a wall,

says Niceno. That’s another degree of complexity. We are currently working on incorporating this into our computer program.

Contact

Dr. Bojan NicenoModeling and Simulation Group,

Paul Scherrer Institute, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 41 49, e-mail: bojan.niceno@psi.ch

Dr. Yohei Sato

Modeling and Simulation Group,

Paul Scherrer Institute, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 26 66, e-mail: yohei.sato@psi.ch