The road to a sustainable energy future leads through the integration of new renewable energy sources, from the sun, the wind, or biomass. Using the Energy System Integration or ESI Platform, research and industry can test promising approaches in all their complex connections and interrelations.

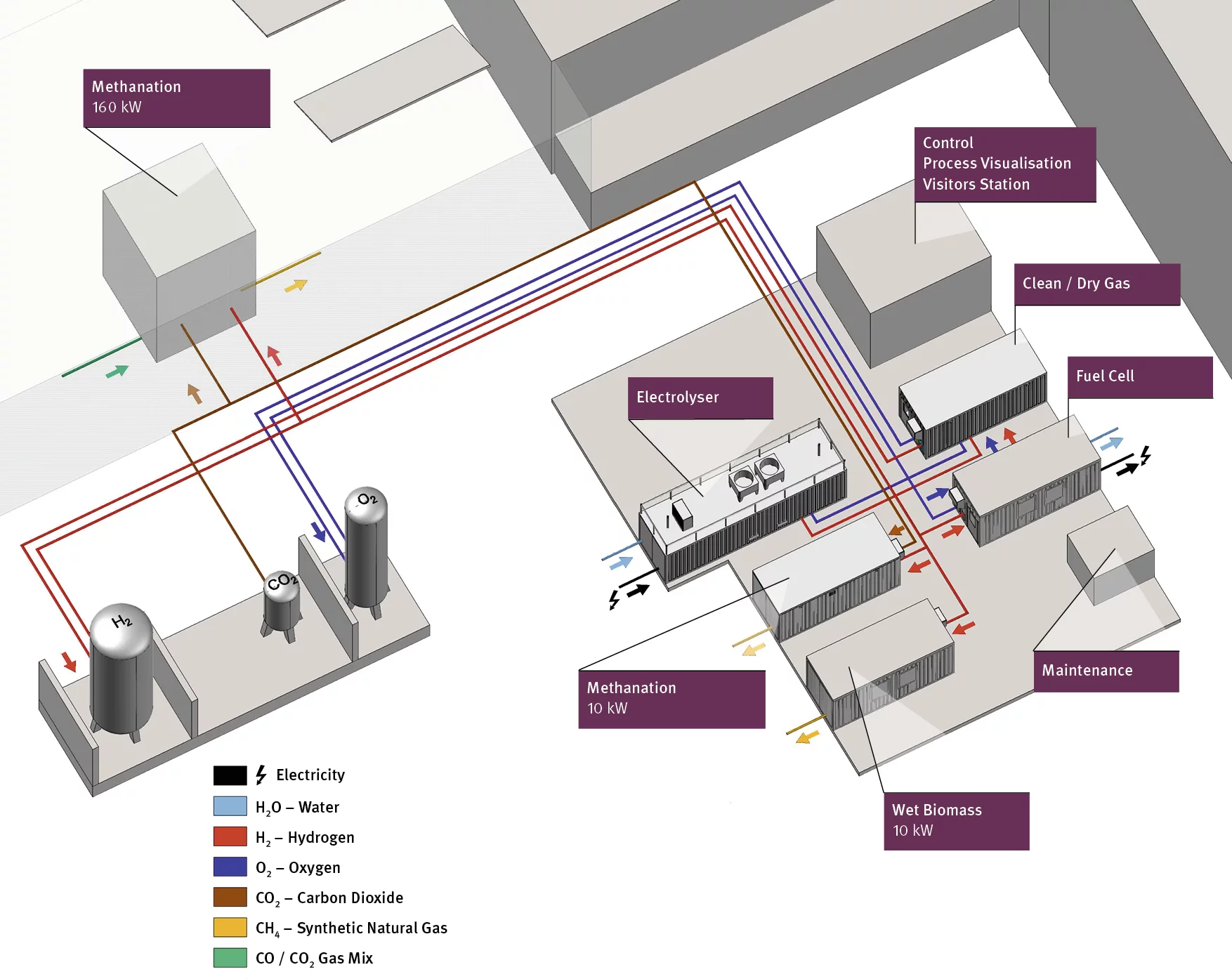

The modular structure of the ESI Platform makes it easily adaptable to the requirements of research. The basic infrastructure ensures provision of electricity and gases as needed for a variety of energy conversion processes. This includes above all hydrogen, oxygen, and carbon dioxide. In addition, other gases such as carbon monoxide and methane can be made available on demand.

Versatile hydrogen

A key element is hydrogen, which is produced by a electrolyser. In the electrolyser, current is used to break water into hydrogen and oxygen. Both gases are stored in pressure tanks. In the ESI Platform, the hydrogen is either processed with carbon dioxide to make synthetic natural gas (methane) or directly converted, together with oxygen or air, back to electric current. The ESI Platform accommodates all of the plant components needed for this, including a facility for drying and purifying the hydrogen and oxygen from the electrolyser.

Methanation at the pilot scale

Carbon monoxide too – as generated, for example, through the gasification of wood – can be converted into methane with the help of hydrogen. Two facilities are available for experimenting with the conversion of carbon monoxide or carbon dioxide to methane (methanation). One mobile, remotely controllable facility enables methane synthesis at a small scale. It can also be transported, if necessary, to an industrial site such as a biogas facility. With a power of 10 kilowatts, it can produce one cubic metre of methane per hour. The ESI Platform also offers a 160-kilowatt methanation facility with which highly scalable performance, to industrial standards, can be achieved.

Putting fuel cells to the test

In addition, hydrogen and oxygen produced by the ESI Platform electrolyser are used to test precommercial fuel cell systems co-developed by the PSI. The goal is to show, for example, how efficient the direct back-conversion to electricity can be for fuel cells operated with pure oxygen. This applies also to testing how such systems can be deployed dynamically in order to balance fluctuations in the power grid.

Extendable, mobile container stations

The ESI Platform is extendable and offers space for different test arrangements. These are housed in containers, which can be either installed in place or mobile, as needed – like the mobile methanation facility. With mobile containers, processes can be tested both at the ESI Platform and at facilities elsewhere. That lends itself particularly well to processes that work with liquid biomass – for example derived from agricultural waste or sludge. Here it is often simpler to take the process to the biomass than the other way around.

Additional information

Overview: ESI Platform – new pathways to the energy system of the futurePartners of the ESI Platform

Contact

Martina Gröschl, Communications DepartmentPaul Scherrer Institute, 5232 Villigen PSI

Telephone: +41 56 310 52 13, e-mail: martina.groeschl@psi.ch