Within Switzerland’s bio-waste a huge amount of precious energy is hidden. That’s because valuable methane, the main constituent of natural gas, can be obtained from it. With a technology developed at PSI, the yield of methane from bio-waste could be increased considerably in the future. A long-term test conducted in cooperation with Energie 360° at the Werdhölzli biowaste digestion and wastewater treatment plant is expected to advance this technology further along its path to industrial use.

Already today, methane is produced from biological waste and sewage sludge in biowaste digestion plants and fed into the natural gas network. However, the raw biogas produced in this way contains not only methane, but also up to 40 percent carbon dioxide (CO2) which in conventional biogas processing must be removed. With a technology developed at PSI, it is now possible to increase the methane yield from bio-waste considerably. The idea behind it is as simple as it is efficient: Instead of going to the trouble of removing the CO2, add hydrogen to the raw biogas and let the CO2 react with the hydrogen to form even more methane.

1,000 hours of continuous testing

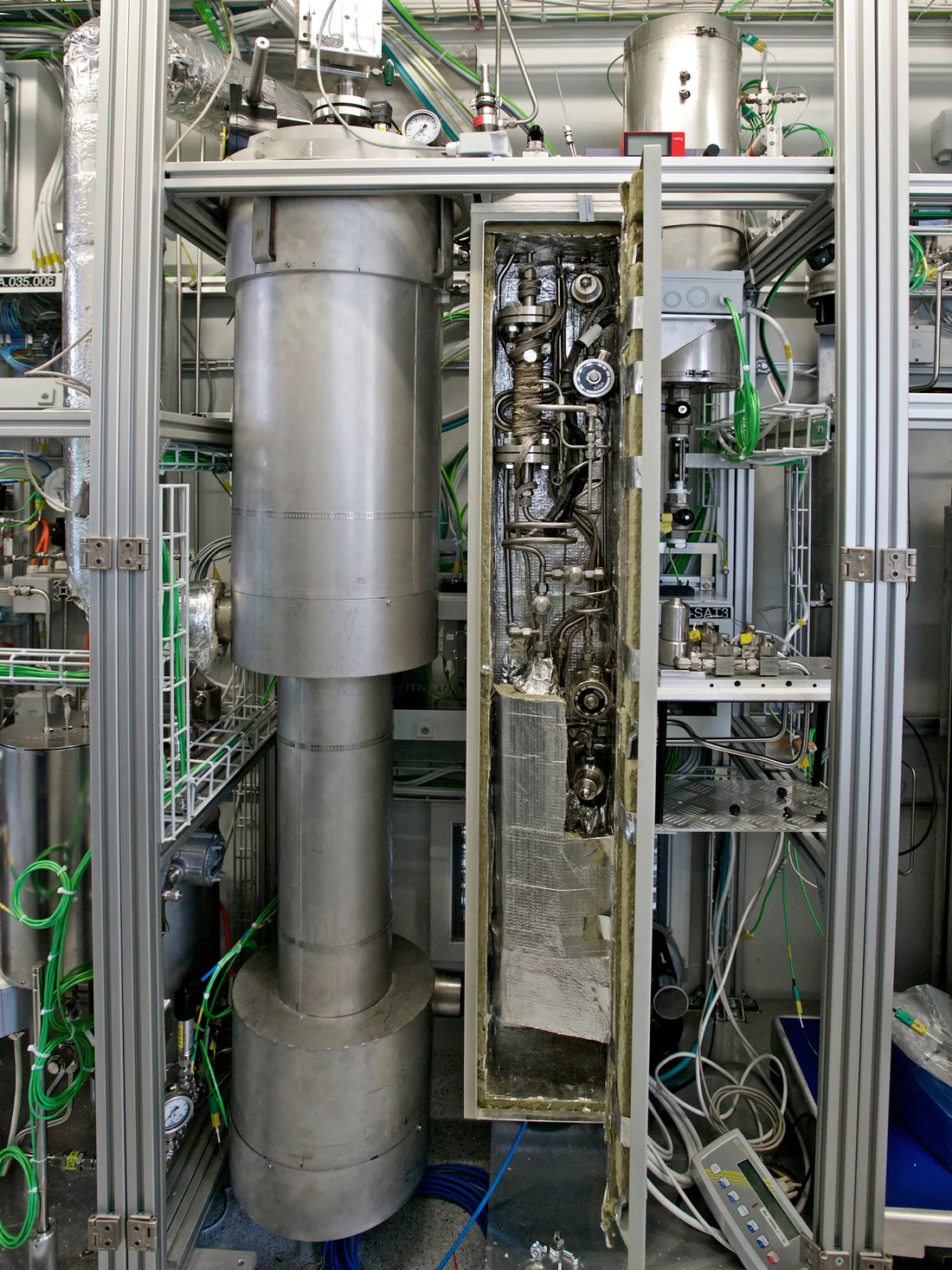

The heart of the technology used is a type of reactor known as a fluidised bed. In it, the raw biogas and the added hydrogen bubble through and mix with particles of nickel catalyst. The catalyst ensures that the CO2 and hydrogen will react and produce methane and water.

A long-duration test to be conducted in spring 2017 together with the Zurich-based energy provider Energie 360° should advance this technology further along its path to industrial use. For this purpose, a mobile demonstration plant, which was put together at PSI, will be set up at the Werdhölzli biowaste digestion and wastewater treatment plant and tested for 1,000 hours of continuous operation under real conditions. “Raw biogas is not always constant in its composition”, says Serge Biollaz, project leader for the PSI, in describing the challenge. “With this test campaign we want to prove that our process delivers a continuously stable result even over a longer time period.”

A contribution to the future energy supply

The potential of the technology is big. Through direct use of the CO2 in the raw biogas, not only is the technology environmentally friendly, but it also allows an especially efficient methane yield from bio-waste resources: “Direct methanation with the introduction of hydrogen could boost biomethane production in already existing biogas plants by around two-thirds”, Biollaz says.

In addition, direct methanation can also contribute to addressing one of the greatest handicaps of the widespread use of fluctuating, renewable energy sources such as the sun or wind: excess electricity. In good conditions, photovoltaic or wind power plants produce more electricity than the power grid can take up. Until now, this power was effectively lost. With so-called power-to-gas conversion, however, the energy can be temporarily stored in the form of gas (be it hydrogen or methane) and made usable for a variety of applications when it’s needed. Hydrogen is directly produced with excess electricity by water electrolysis. In the case of direct methanation, hydrogen is further converted to methane and stored efficiently in the natural gas grid.

Economic viability is crucial

As promising as direct methanation is, the fact that it’s technically feasible and environmentally sound is not enough to justify its industrial-scale use: “It is also necessary to ensure that a plant of this type can be operated economically”, Biollaz stresses. Therefore assessing the economic viability of direct methanation within the context of biogas processing is part of the project as well.

The ESI Platform at the PSI

The demonstration plant called Cosyma (Container-based System for Methanation) is part of the Energy System Integration Platform of the PSI. The ESI Platform started operating in the fall of 2016. Its goal is to investigate, in close collaboration with partners from research and industry, the technical and economic viability of different variants of power-to-gas technology.

Text: Paul Scherrer Institute/Martina Gröschl

Additional information

Overview: ESI Platform – new pathways to the energy system of the futurePartners of the ESI Platform

Contact

Dr. Serge Biollaz, Group Leader, Thermal Process Engineering, Paul Scherrer Institute, 5232 Villigen PSI, SwitzerlandTelephone: +41 56 310 29 23, e-mail: serge.biollaz@psi.ch [German, English, French]