Cement holds the world’s buildings together. The binding agent for concrete and other construction materials is, if assessed by global production volumes, one of the world’s most important assets. However, cement production consumes vast amounts of energy – and this is largely obtained by the combustion of fossil fuels. Scientists at the Paul Scherrer Institute and the globally-active Swiss cement manufacturer Holcim want to change this.

Together, they are developing a process that can create a high-quality environmentally-friendly fuel for the cement kilns of the future from carbon-rich waste using concentrated solar energy. In a collaboration project run over several years between Holcim and the ETH, Zurich, PSI-researchers have taken the first step towards the production of solar cement

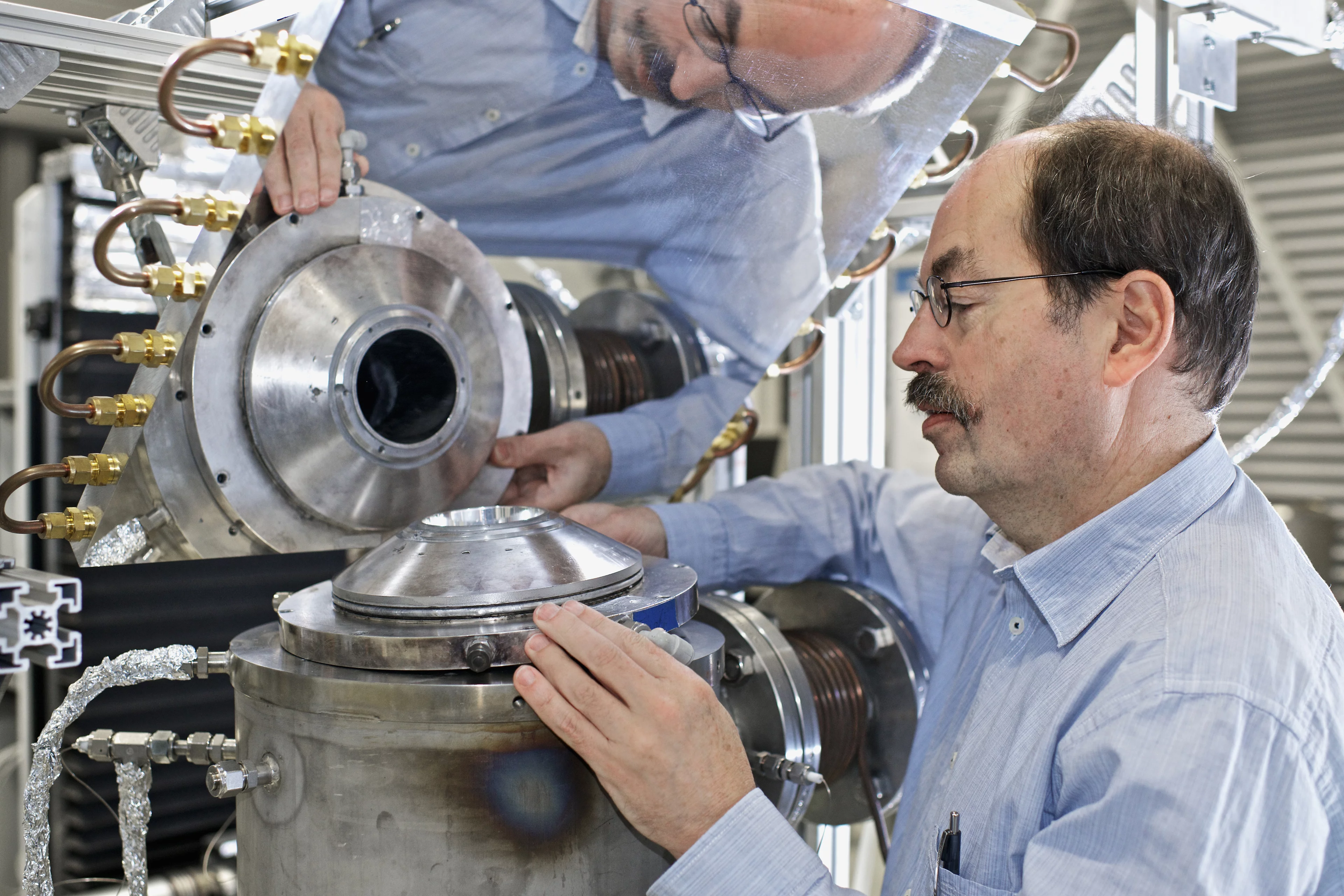

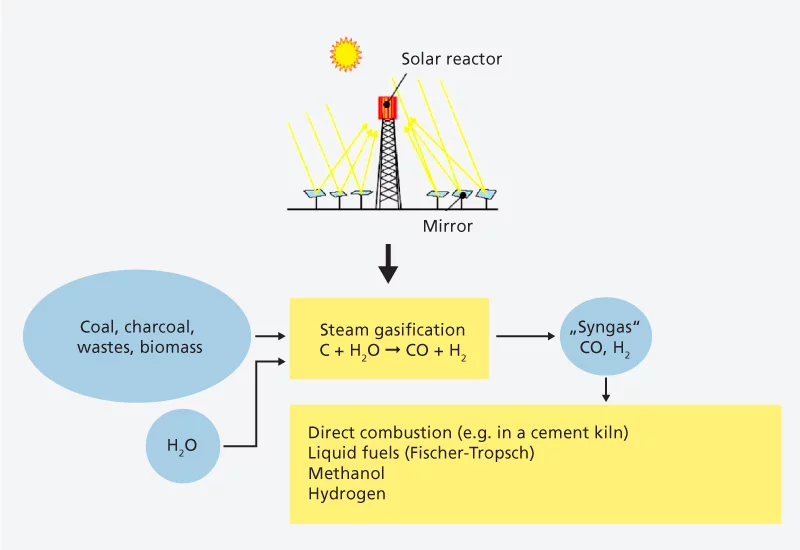

. Researchers used a solar reactor, developed at PSI, in which sunlight was focussed by mirrors to an intensity of several thousand suns. Inside this solar-heated oven, temperatures in excess of 1,200 degrees Celsius can be attained. This enables low-grade coal, biomass or carbon-rich wastes such as plastic- and tyre chips or sewage- and industrial sludge to be gasified by the addition of water vapour. The resultant gas is mainly composed of hydrogen and carbon monoxide, a mixture known by professionals as synthesis gas

. This syngas

is an excellent fuel that can be used for heating cement kilns. One of the distinct advantages of this solar technique is that the synthesis gas produced contains up to 40 per cent more energy than the waste used as the starting material. The extra energy is that which is supplied by the sun, and retained after gasification during synthesis of the gas. Thanks to this solar component, the carbon footprint of gas produced in this way is significantly more favourable than that currently produced by conventional gasification processes.

Whilst developing this solar process, PSI scientists had to progress in a series of small steps. First, solar gasification alone was tested in laboratory scale reactor. The PSI's high-flux Solar Simulator was used as an energy source in place of natural sunlight. The Solar Simulator is immune to the vagaries of the weather: inside, 10 xenon lamps deliver a radiation intensity of up to 10 000 Suns, focussed onto a small area. This system is highly valuable for any experiment that requires high temperatures and precise reproducibility.

Scale-up in Almeria

Next, they stepped outside of the laboratory and did something more daring. These scientists built a solar reactor with a capacity about 25 times greater, and installed this energy stream into a unique facility, the Solar Platform in Almeria, Spain. Here, with the help of 300 sun-tracking mirrors, the sun is focussed at the top of a tower. For their experiments, the scientists placed the solar reactor half way up the tower, and focussed the sunlight onto it with the help of 75 mirrors. In the future, if a similar solar oven

were to be operated commercially, this could be located at the base of the tower, to facilitate access during operations.

The tests at Almeria proved the solar reactor was suitable for gasification of a range of very different types of carbonaceous waste. Thus, the world’s first solar-powered synthesis gas production was performed successfully and reproducibly at this scale. Overall, scientists discovered this method also allowed large, bulky and moist waste materials to be used without any pre-treatments, and that the synthesis gas production rate was strongly dependent on the material used.

In the future scientists want to improve further details. For example in the nature of the water vapour supplied to the reactor. Currently, the steam for the gasification is passed into the material to be gasified via 4 feed lines. Preliminary trials at Almeria have indicated the use of a finer steam distribution could increase the efficiency of the gasification process even further.

Scientists still need to hone these and other details to optimise their technology. Their long term goal is to build a solar reactor with sufficient power to satisfy a significant proportion of the energy needed to operate a commercial cement kiln.

In addition to use as a fuel for producing cement, which stands at the forefront of this project, solar produced syngas could also be further processed into a high-quality and easily stored energy source. One very promising example is its conversion into liquid fuels like gasoline, based on the established Fischer-Tropsch process.