Lithium iron phosphate batteries are very durable and can be charged relatively quickly. Researchers from the Paul Scherrer Institute (PSI), ETH Zurich and Toyota Central R&D Labs, Inc. reveal the reasons for these properties in a new study. During the charge and discharge process for this kind of battery, lithium ions need to move between the two electrodes. As it turns out, the rapid charging of these batteries is down to the fact that, at a higher charging voltage, the lithium ions are distributed evenly across the volume of the particles that make up the battery electrode, which contains lithium. This even distribution renders the lithium ions in the battery more mobile and the battery charges more swiftly. If a lower voltage is applied to charge the battery, however, the lithium ions collect in a thin layer in the particles of the electrode and therefore start moving much more slowly, which results in slower charging. The findings were made possible thanks to measurements using a new method at the Swiss Light Source (SLS) at PSI. The measuring technique developed for the experiments could also be applied to other battery materials that also enable rapid charging.

Batteries play an increasingly important role in today’s energy world. Not only do they store energy to power countless mobile electronic devices, but also the surplus electricity produced by wind turbines and solar panels. Lithium ion batteries are especially ideal for energy storage in electric cars. The lithium iron phosphate battery (LFP, which is short for the chemical formula of the cathode material used (LiFePO4)) has performed particularly well in this field in recent years. It can be charged relatively quickly and its trump card is its long durability, which is a major advantage for cars. A new study headed by researchers from the Paul Scherrer Institute (PSI) now reveals why LFP batteries can be recharged so rapidly.

Ramp versus step. Why LFP batteries can be recharged so rapidly.

While an LFP battery is charging, electrically charged lithium atoms (ions) are forced out of the battery’s positive LiFePO4 electrode and into the negative electrode, which is usually made of graphite, under the influence of an electric current. On the way, the lithium ions travel through the electrolyte, the fluid that connects the two electrodes to one another. While discharging, the lithium ions move back in the opposite direction and electricity flows through the device connected to the battery.

The lithium in an LFP battery is initially present in the form of almost spherical particles in the positive electrode. At low charging voltages, lithium is extracted from one side of the particles first. This results in a side that has virtually been emptied of lithium and another side filled with lithium. At the boundary between these layers, a steep, step-like gradient in the lithium concentration develops. Additional energy now needs to be added to the lithium ions that are located at the thin boundary layer and move sideways during charging – not only for them to move forwards, but also actually scale the step

. This inhibits the movement of the ions in the battery, which slows down the charging process.

As it now turns out, such inhibitions are reduced if the battery is charged at a higher voltage. The reason: the step-like concentration gradient gives way to a gentle, ramp-like progression of the lithium concentration. This is because, at higher voltages, the lithium ions involved in the charging process are distributed across the volume of the electrode particles for brief moments as opposed to being herded together in a thin layer boundary. As a result, the lithium can be set in motion more easily during charging, without the need for more energy to be added to negotiate the layer boundary. The following image illustrates the difference in charging speed: when charging slowly, the sharp divide between two layers is equivalent to a high step. The lithium ions literally queue up in front of this step because they are only able to scale it one at a time. In the case of rapid charging, however, there are times when the lithium is distributed across the volume of the particles, which acts more like a ramp and enables all the lithium atoms to move upwards at the same time.

Like a long-exposure shot of the starry sky

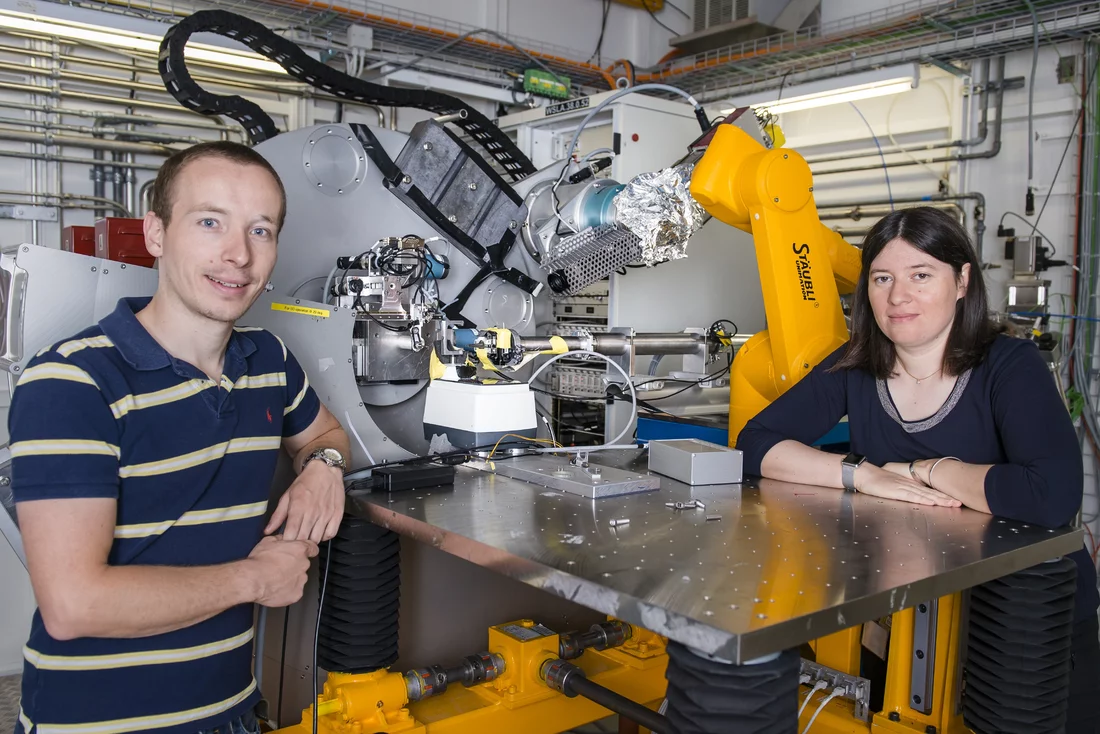

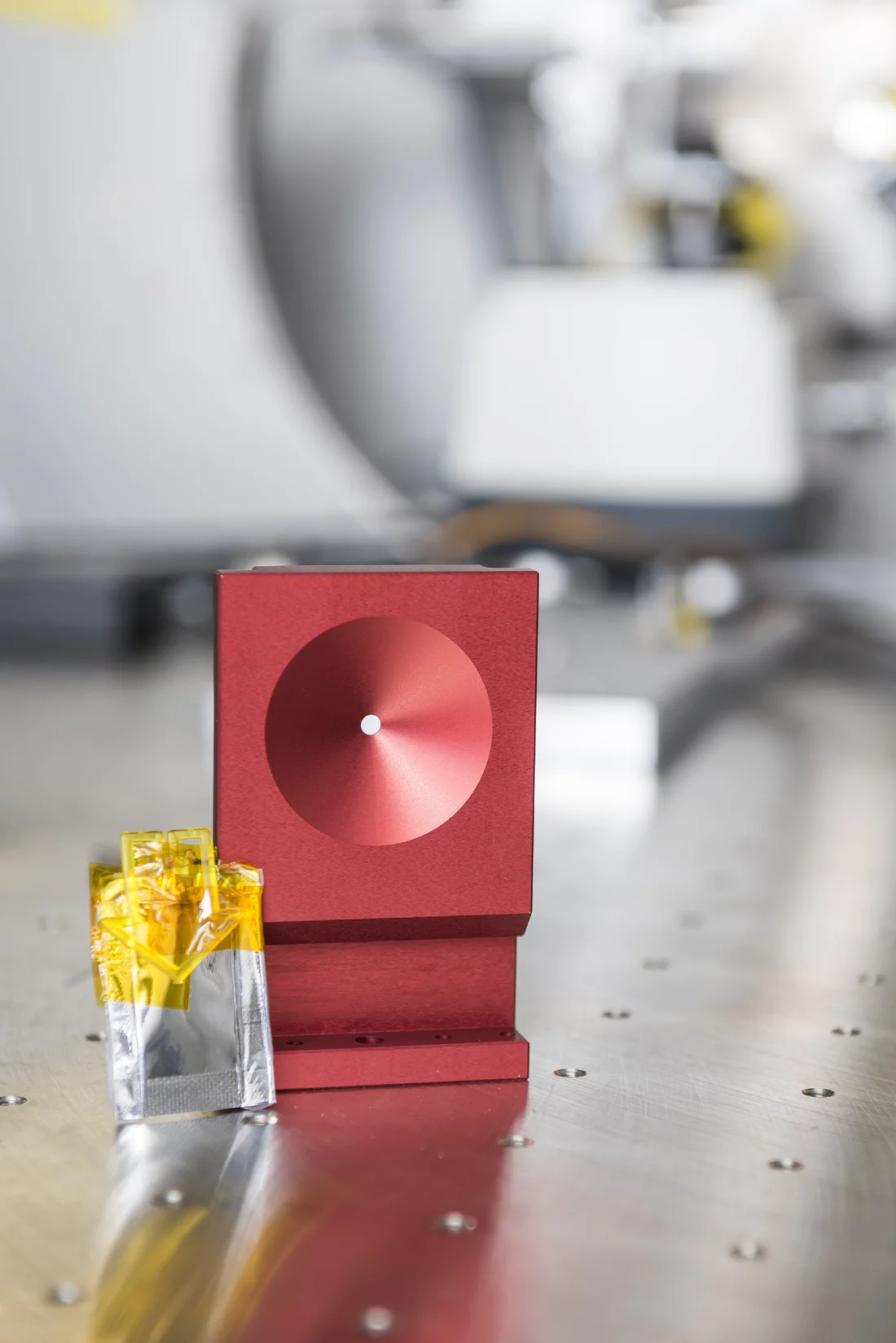

Thanks to measurements conducted at the Swiss Light Source (SLS) at the Paul Scherrer Institute (PSI), the scientists were able to demonstrate that the lithium level in the electrode particles increases steadily from outside to inside as opposed to abruptly during rapid charging. For these measurements, x-ray light was used to track changes in the structure of the electrode material during charging and discharging. The method is based on the bending (diffraction) of the x-ray light by the material’s atoms. This bent x-ray light produces a so-called diffraction pattern of light and dark patches on a detector, from which the researchers are able to deduce the arrangement of and distance between the atoms in the material. As the distance between the atoms depends on the lithium level in the surrounding area, the diffraction pattern also reveals the distribution of the lithium content in the particles.

The material in the particles displays a regular, three-dimensional lattice structure, in which every atom occupies a particular place. In the case of slow charging, the lattice structure in the LFP particles is the same in both layers. The distance between the atoms, however, depends on the lithium content and is therefore different in every layer. This distance changes if lithium is removed from the outer layer, which is visible in the diffraction pattern: in the case of slow charging, the pattern consists of two light areas (one for each layer with their different atom distances), which are separated by a dark area.

If the sharp boundary disappears during rapid charging, new areas of medium brightness become visible in the diffraction pattern. These additional light areas stem from parts of the particle with several different lithium level values and therefore other atom distances. Consequently, they are an indication that the lithium is no longer concentrated in a layer, but rather distributed evenly across the particles.

The intermediate states that enable rapid charging are short-lived: they appear and quickly vanish again during charging. As a result, their signal is very weak in a diffraction pattern if only one charging process is observed. To enable them to become more clearly visible, the authors of the study took a long-exposure image spanning several charging processes. In principle, it is like a shot of the starry sky, where the photographer opts for a low shutter speed to gather sufficient light from the stars. Here, the scientists collected the light diffracted by the intermediate states during several charging cycles as the short-lived intermediate states would have yielded too weak a signal during one single charging.

Petr Novak, lead scientist of the study and head of the Electrochemical Energy Storage section at PSI, sums up the significance of the study thus: Using our novel measuring technique, we confirmed some theories and debunked others that endeavour to explain the rapid chargeability of LFP batteries.

Novak also has one eye on the future: Our results not only enable us to understand the LFP battery better and help refine it; the measuring method we developed will also enable us to study materials that are used in other batteries that can be charged just as quickly. Therefore, other battery types also stand to benefit.

Text: Paul Scherrer Institute/Leonid Leiva

About PSI

The Paul Scherrer Institute PSI develops, builds and operates large, complex research facilities and makes them available to the national and international research community. The institute's own key research priorities are in the fields of matter and materials, energy and environment and human health. PSI is committed to the training of future generations. Therefore about one quarter of our staff are post-docs, post-graduates or apprentices. Altogether PSI employs 1900 people, thus being the largest research institute in Switzerland. The annual budget amounts to approximately CHF 380 million.

(Last updated on April 2015)

Additional information

Electrochemical energy storage section of the Electrochemistry Laboratory at PSIContact

Prof. Dr. Petr Novak, Head of the Electrochemical Energy Storage SectionPaul Scherrer Institute

Telephone: +41 56 310 24 57

E-mail: petr.novak@psi.ch [German, English]

Dr. Claire Villevieille, Group leader Battery materials

Paul Scherrer Institute

Telephone: +41 56 310 24 10

E-mail: claire.villevieille@psi.ch [French, English]

Dr. Michael Hess

ETH Zurich

Integrated Systems Laboratory

Telephone: +41 44 633 8986

E-mail: hess@iis.ee.ethz.ch [German, English]

Original Publication

Combined operando X-ray diffraction-electrochemical impedance spectroscopy detecting solid-solution reactions of LiFePO4 in batteriesMichael Hess, Tsuyoshi Sasaki, Claire Villevieille, Petr Novák,

Nature Communications 8 September 2015

DOI: 10.1038/NCOMMS9169