In many European countries, gas and steam power plants (CCGT plants), also known as combined cycle power plants, are included as options for a safe energy supply. In the 2050 Federal Government Energy Strategy, they are mentioned as a possible replacement for the nuclear power plants that are being phased –out. Combined cycle power plants convert natural gas into electricity using a combination of gas and steam turbines, with very high efficiencies, of around 60 percent. Furthermore, since these power plants can be started up and shut down very quickly, they are ideally suited for compensating production fluctuations from wind and solar power plants. However, their CO2 emissions, whilst the lowest of all conventional power plants using fossil fuels, are still significant. Researchers at the Paul Scherrer Institute are working on a solution for this within the framework of a European Union project.

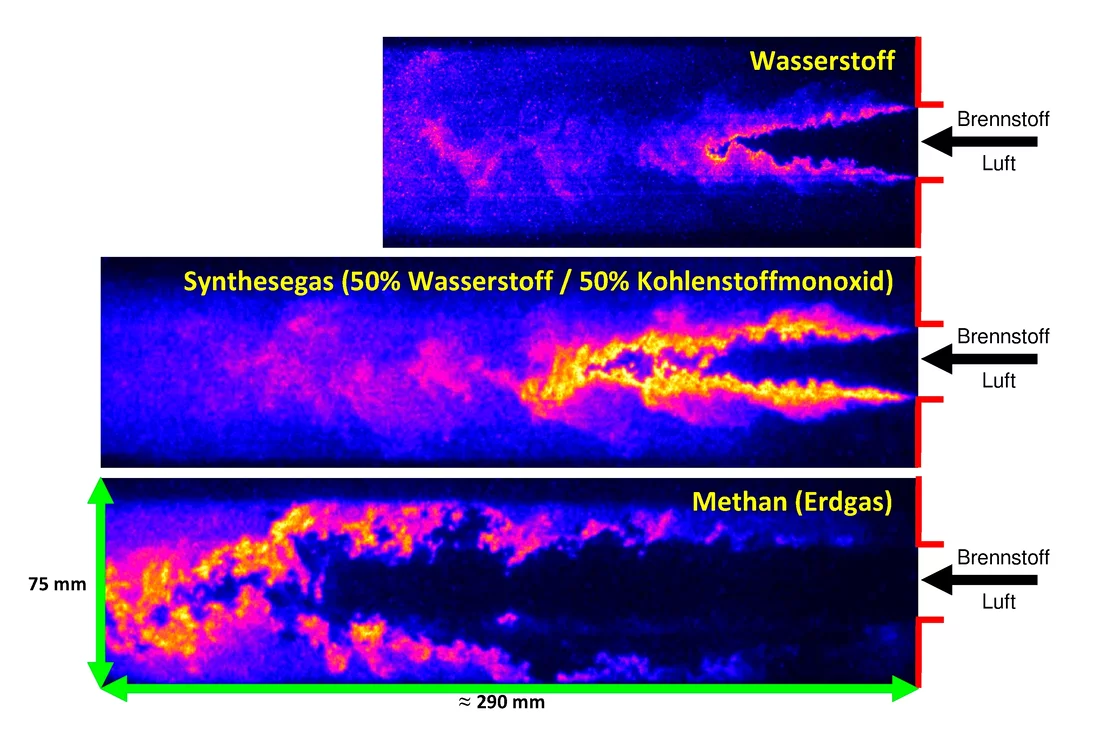

In the EU funded "H2-IGCC” project the issue is one of developing a configuration for combined cycle power plants, in which the CO2 can be separated inside the power plant prior to combustion. The fuel used in combined cycle power plants is usually natural gas, which mainly consists of methane. However, other fuels can be used too - for example syngas, a mixture of hydrogen (H2) and carbon monoxide (CO), derived from the gasification of hydrocarbons (such as coal, refinery residues and biomass). The advantage of using syngas as a fuel is that the CO can easily be separated from it as CO2 before combustion, instead of after the combustion from the exhaust gas of the combined cycle power plant. For this purpose the CO in the syngas mixture is converted to CO2 by adding water vapour, in a process known as the "water gas shift” reaction. Thereafter, the CO2 is washed out, compressed, and stored in a suitable storage tank.

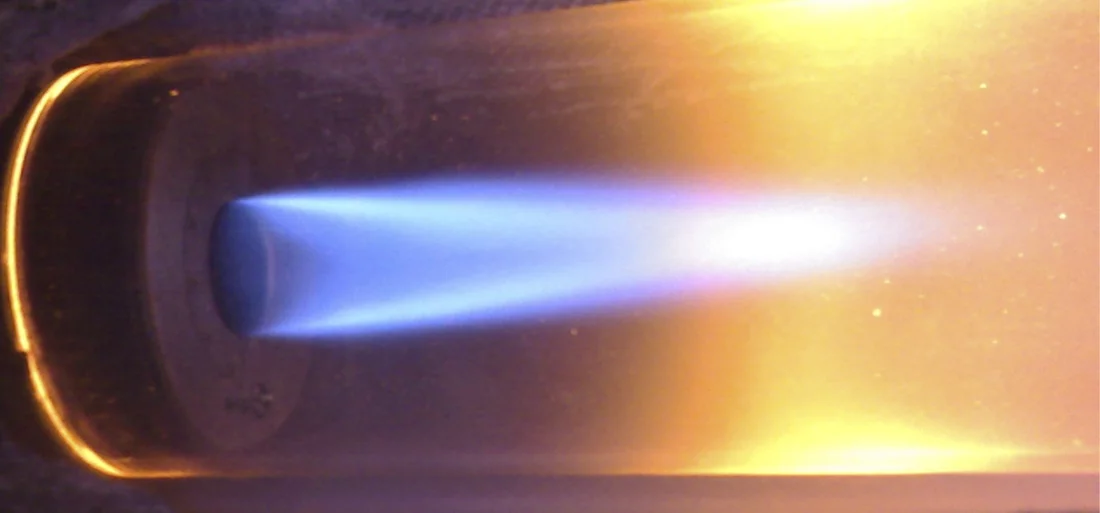

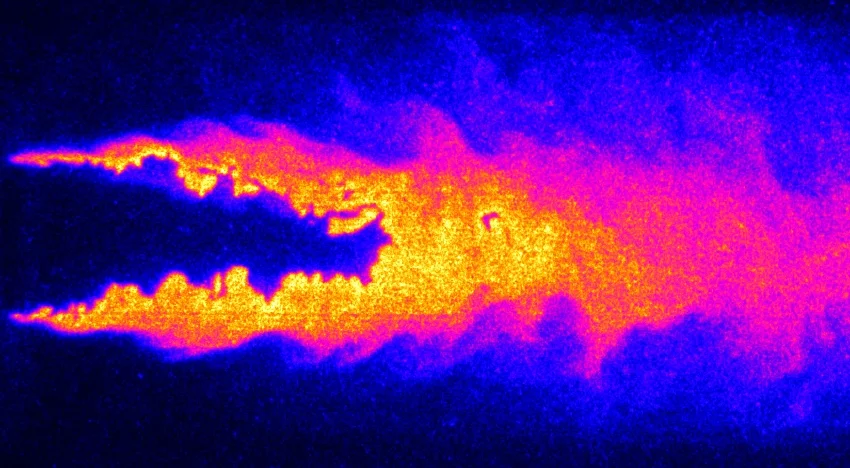

After these processing steps, hydrogen remains, rendering the composition of the residual syngas to about 70 percent hydrogen by volume.This hydrogen-rich fuel is indeed "clean", but places much higher stresses on turbine components. Because hydrogen is more reactive than syngas, it burns much more intensely than the natural gas fuels typically converted in a gas turbine. Firstly, a hydrogen-rich fuel ignites faster, so combustion can take place before the fuel and air are sufficiently mixed. This can in turn lead to an increase in the emission of harmful nitrogen oxides (NOx). Early ignition also means that the combustion proceeds near to the fuel inlet, which exposes components at this point of the combustion chamber to increased thermal stress. Secondly, the hot exhaust gas from the combustion chamber, which drives the turbine, contains more water vapor than for syngas or natural gas combustion. Since water vapor enhances the heat transfer very efficiently, the turbine blades are heated up even more. This effect has to be compensated for by improved cooling for these turbine components resulting in additional loss in efficiency. Contributions from PSI-Researchers

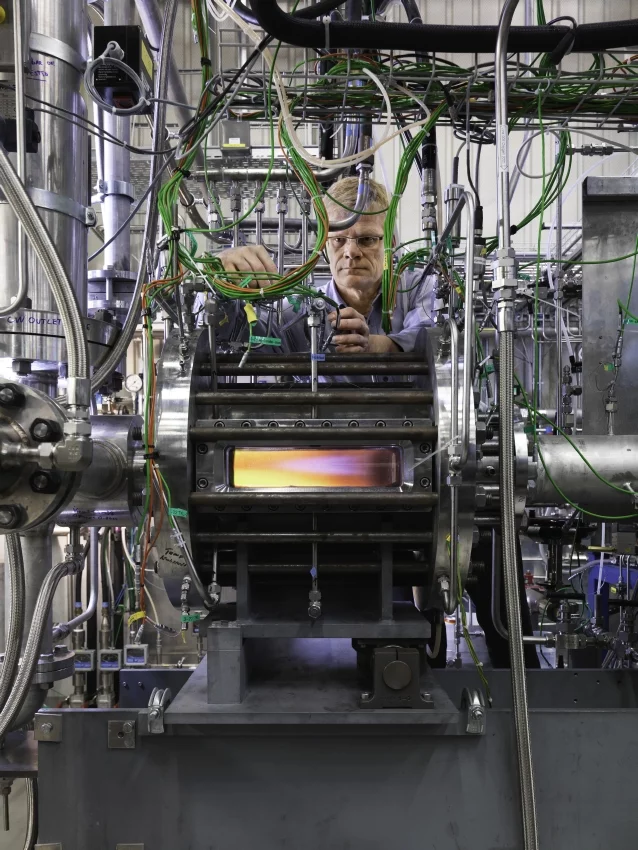

PSI has been involved with the "Combustion" part of the H2-IGCC project. The aim is to examine the efficiency and emission standards of modern combined cycle power plants that use hydrogen-rich fuel. Using a set of specially developed techniques, PSI scientists are studying how the flame develops inside the combustion chamber, and how the ignition point of the fuel could be controlled.The experiments are run in a PSI test chamber, to which researchers have access via viewing panels. Through these "windows", a laser light can be shone into the combustion chamber, with which flame front characteristics and the chemical compounds present in the reaction zone can be detected in real time. The experiments are supported by detailed computer simulations of the combustion processes.

In the first two years, project partners have further developed the concept of a gas turbine with hydrogen-rich fuel with all its sub-processes. In 2013, at the end of the current phase of the project, the combustion chamber concept will be demonstrated under real operating conditions. In a follow-up project, it is envisioned to set up a pilot plant based on this concept.