The striking round building housing the Swiss Light Source SLS is getting a new roof: In the course of the SLS 2.0 upgrade, the old tarpaper is currently giving way to a new shell made of aluminium profiles with integrated photovoltaics.

Scaffolding covers the first third of the circular building. It’s only on second glance that you see that this construction, consisting of metal tubes, arches over the deep roof of the Swiss Light Source SLS but doesn’t touch it anywhere. An ingenious design with counterweights. There’s always a hands-breadth of air beneath the rods. «This enables us to renovate the entire surface without interruption,» explains Markus Jörg, head of Infrastructure and Electrical Installations. When the Swiss insurance institute Suva approved this scaffolding, it gave it the rating «excellent,» Jörg continues.

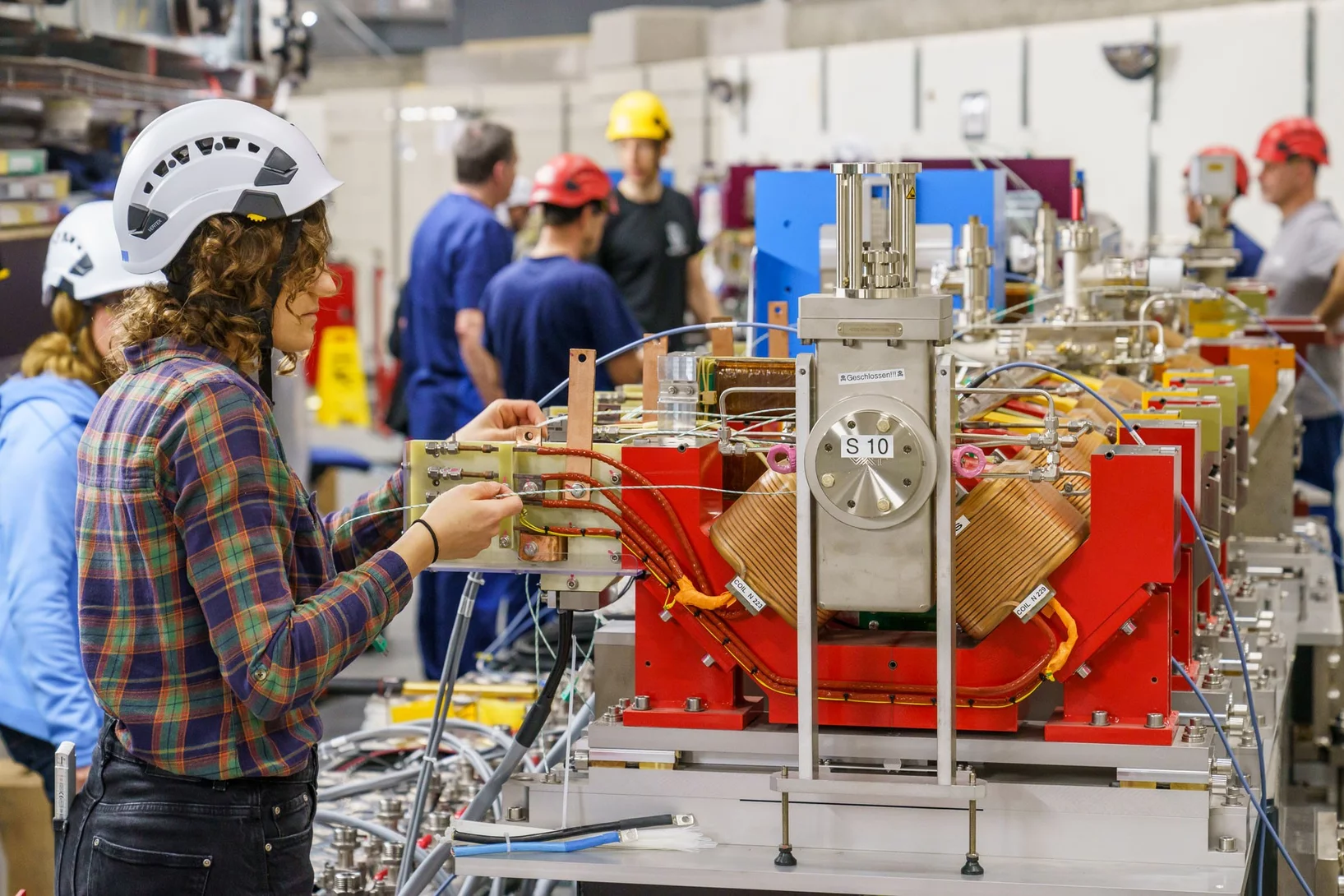

The construction work on the roof is part of the SLS upgrade currently under way. The upgrade project known as SLS 2.0 is renovating, first and foremost, the heart of the large research facility, which is a good 20 years old: A new electron storage ring will increase the intensity and concentration of the X-rays generated here by a factor of 40. This will enable novel research and more precise scientific experiments than ever before. Since the end of September 2023, research has been paused for the sake of this conversion. And work can also be done on the shell of the building.

Staircase 3

It is mid-May 2024, and heavy clouds are threatening, but as long as it’s dry, the work goes on. Markus Jörg leads the way around the building, a short walk from the SLS entrance, until a sign on the scaffolding marks Staircase 3. Like a sign in a theatre, except that here there’s no charge for admission. A metal staircase leads upwards, with the floor slightly swaying, until finally it’s a small step to cross the gap between scaffolding and roof.

Construction of the scaffolding started in early December 2023 and took around two months, Markus Jörg explains. As soon as it was in place, the old covering on the lower areas of the roof was dismantled. These side pieces run around SLS in three slightly overlapping rings, which is why Jörg calls them the scales of the SLS, as if the building were a big fish.

The old covering consisted of tarpaper, a moisture barrier impregnated with bitumen. It gave SLS its anthracite grey exterior, which over the years was overgrown with moss. Some praised this as an understatement, below which the cutting-edge research of SLS was camouflaged.

When you reach the main roof, above the scales, you can see the different layers of construction. On the first third, the tarpaper has already been removed; the old insulation that was underneath will go for recycling. It is being replaced by a new, 16-centimetre-thick layer of glass wool. The new insulation rests on a sealing film, the so-called vapour barrier. Under this, in turn, is the wooden vault of SLS, which is also visible inside the building. When you walk across the roof, you can feel that it sways less when you are on top of one of the distinctive support beams.

A fish with hedgehog spines

«Beware of the spacers,» Markus Jörg warns. On most of the upper roof surface, the new insulation is yet to be installed, but the black spacers made of durable plastic have already been screwed in at regular intervals. As if SLS now had hedgehog spines.

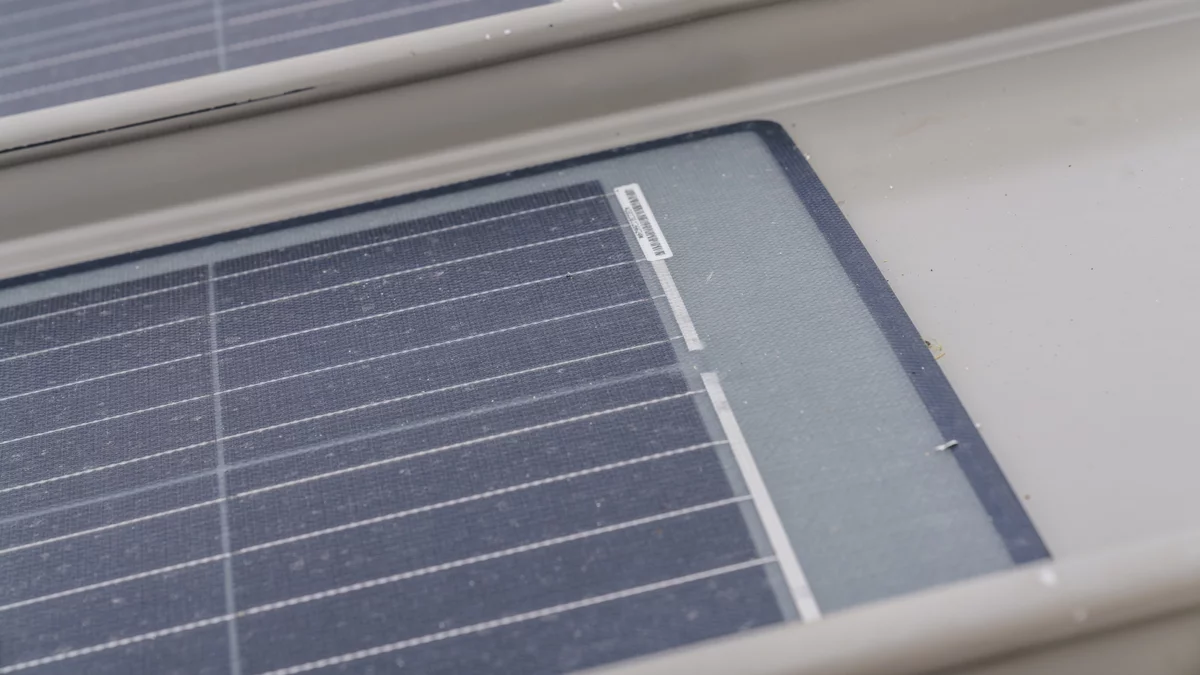

It’s on these spacers that the final layer of the new roof will rest: aluminium profiles with pre-attached solar modules. The profiles are sheets of metal, each several metres long and between 25 and 45 centimetres wide. The exact dimensions of the individual profiles vary, because the pieces are perfectly tailored to fit the vaulted SLS roof. The profiles are hooked into each other at the sides and pressed together; lengthwise they will be welded together so that ultimately everything is rainproof.

The total surface area of the SLS roof is 17,600 square metres. The area of the main roof is 12,500 square metres, and the scales add another 5,100 square metres. Two kinds of aluminium profiles are being deployed: those with solar modules – all around the main roof and on the scales on the south side – and and those without solar modules in the areas where the sun hardly reaches.

Up to 33 % electricity savings

When SLS goes back into operation in 2025, it will require up to 33% less electricity than before, despite providing significantly more intense synchrotron light. These savings are due mainly to the state-of-the-art permanent magnets that are currently being installed in the electron storage ring, replacing the power-hungry electromagnets previously used. Another contribution to electricity savings comes from the new semiconductor amplifiers – replacing the previous tube amplifiers – that will further accelerate electrons in the storage ring. At the same time, the entire cooling process of the facility is being optimised; in the future it will also include optimised heat recovery, boosting heat recovery power by a factor of 20. And finally, the solar power that is provided by the new roof and flows directly into the operation will reduce PSI’s external energy demand.

On the way back over the hedgehog spines, Jörg points out one of their special features: The upper end of the spacers is designed in such a way that the aluminium profiles can move freely on them. That is important because the material heats up in the summer and expands as a result. «Plus, we now get a lightning rod for free: Aluminium conducts electricity,» Jörg says happily.

The steps of Staircase 3 lead back down. Once one third of the roof is finished, the entire scaffolding will be shifted clockwise to the next third. Suva will therefore be inspecting the construction two more times. Markus Jörg says goodbye for today. As head of the infrastructure and logistics subproject of SLS 2.0, he has an especially full calendar at the moment.

Text: Paul Scherrer Insitute PSI/Laura Hennemann

© PSI provides image and/or video material free of charge for media coverage of the content of the above text. Use of this material for other purposes is not permitted. This also includes the transfer of the image and video material into databases as well as sale by third parties.

Contact

Markus Jörg

Head of Infrastructure and Electrical Installations

Paul Scherrer Institute PSI

+41 56 310 50 08

markus.joerg@psi.ch

[German, English]