Filtering soot and reducing nitric oxide in the same place – engineers have been working on combining these two important tasks of exhaust gas after-treatment in vehicles for a number of years. As researchers from the Paul Scherrer Institute now reveal, this is not unrealistic. At any rate, it shouldn’t fail because of soot.

A mixture of emissions that are harmful to health and the environment is formed during diesel combustion in vehicle engines. These include nitric oxide and soot particles – emissions that until now have been captured in separate parts of a vehicle’s exhaust gas treatment system and have only partially been neutralised, before they reach the environment. Due to this spatial separation more space is required for the after-treatment of exhaust gas. However, for vehicle manufacturers, every cubic centimetre they can save counts. Consequently, the development of compact systems for the after-treatment of exhaust gas is fairly high on their list of priorities. For some time, engineers in the development departments of many vehicle manufacturers have thus set their sights on a device where soot particles from the diesel combustion can be captured and simultaneously nitric oxides can be reduced to harmless nitrogen.

From nitric oxides to harmless nitrogen

Nitric oxides are converted into harmless nitrogen during exhaust gas after-treatment through so-called selective catalytic reduction (SCR). As the name suggests, this requires a catalyst to render the reduction of the nitric oxides faster and more efficiently through a reaction with ammonia. The ammonia is previously formed from the decomposition of urea, which is stored in a tank on board and only injected into the exhaust gas stream as and when needed.

If one wants to reduce nitric oxides and filter soot in the same place, one needs to ensure that diesel soot will not interfere with the catalysis of the nitric oxide reduction. After all, the carbon that the soot is composed of is reactive and in such a combined exhaust gas after-treatment system, comes into contact with nitric oxides, oxygen, ammonia and urea, which multiplies the reaction possibilities compared to spatially separate components.

Might soot be getting in the way?

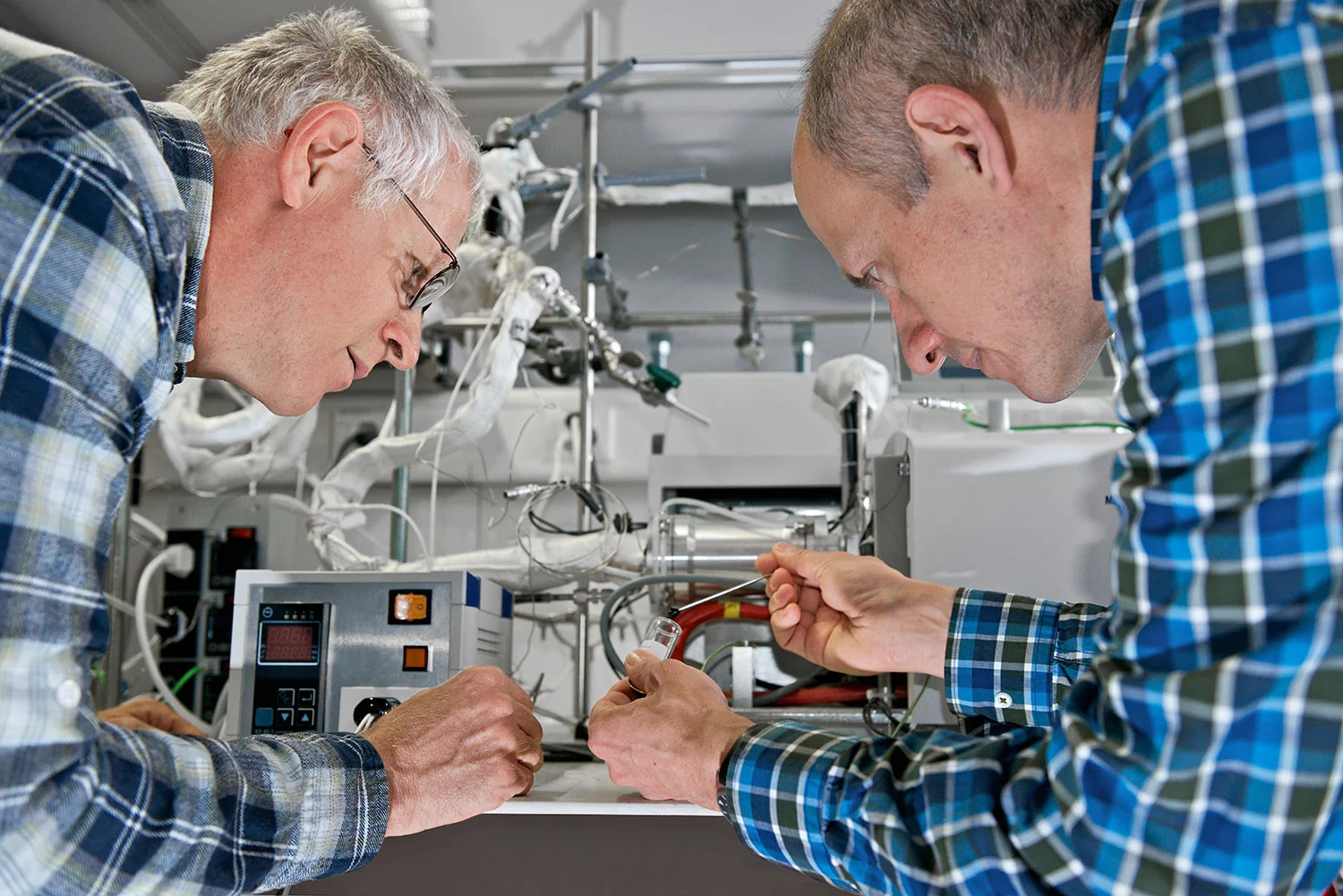

In his dissertation, PSI doctoral student Max Mehring examined the impact that the deposition of soot has on the function of the SCR catalyst under realistic conditions. His results reveal that instead of being an interference factor, soot can actually aid the catalytic conversion of nitric oxides into harmless nitrogen.

Mehring and his colleagues from the Bioenergy and Catalysis Laboratory demonstrated this with experiments where they studied different soot samples, including artificially manufactured soot and real soot samples produced by heavy-duty engines. The researchers tested the catalytic effect of soot at temperatures and gas-flow speeds that can typically occur in a vehicle’s partial load operation. High temperatures and slow gas flows usually boost the catalytic reduction of nitric oxides, a familiar correlation that was confirmed here once again. The scientists also discovered that soot only favoured the reduction of nitric oxides if nitrogen dioxide was present in the gas mixture. Fortunately, nitrogen dioxide is present in the exhaust gas stream in practice: in the customary gas after-treatment chain, this gas is produced in the diesel oxidation catalyst, whereupon it finds its way into the SCR catalyst. But, nitrogen dioxide is mostly produced in insufficient amounts in the SCR catalyst, and thus remains the limiting factor in practice. Once the nitrogen dioxide has been used up, the soot immediately ceases to have a catalytic effect in the reduction of nitric oxides.

Good news for developers

However, as long as nitrogen dioxide is available, the soot contributes in the reduction of the nitric oxides with at least five per cent of the total reduced amount. “Although this isn’t a huge amount, it’s good news for the developers, who have one main fear: that soot deposits might choke the reduction of nitric oxides,” says Oliver Kröcher, Head of the Bioenergy and Catalysis Laboratory. “But as our projects show, this isn’t the case,” he adds.

Text: Paul Scherrer Institut/Leonid Leiva

Contact

Dr. Oliver Kröcher, Head of the Laboratory of Bioenergy and Catalysis, Paul Scherrer Institute,Telephone: +41 56 310 20 66, E-Mail: oliver.kroecher@psi.ch