The safety standards for nuclear power plants in the western world concerning the selection, implementation and monitoring of materials are very high. The requirements depend on the loads and safety profile of various components and their expected service life. Additionally, these requirements have to be met during normal operation as well as in the event of an operational incident. Many components of a nuclear power plant, such as fuel elements, pumps or valves, are designed from the outset for only a limited lifetime. Others however, especially large components such as the reactor pressure vessel, should in principle last as long as the nuclear plant itself.

Scientists at PSI are studying the behaviour of components which have a long lifetime. They are interested, for example, in the role of stress corrosion cracking in materials and the effect of strong radioactive radiation, which can be seen in components after their normal operation in a nuclear power plant or after an accident. These studies enable conclusions to be drawn with regard to ageing, corrosion and damage mechanisms.

Each material, regardless of where it is used, is subject to ageing over time as a result of very small structural damage. One of the objectives of materials scientists at PSI is to determine what this damage looks like, the mechanisms that caused it and whether a prognosis can be established from this snapshot. The ultimate aim of this research is always to make nuclear power plants ever safer. To achieve this, the scientists study very small samples, with dimensions of a few nanometres (nano is a prefix adopted from Greek, which is used to indicate the billionth part of a physical unit ― thus a nanometre is one billionth of a metre, or one millionth of a millimetre).

Pressure stamps for dwarfs

There are two reasons for using microscopically small samples. Firstly, the components to be studied in the reactor remain as undisturbed as possible, so the studies do not cause them to become unstable; in this case, the damage caused when taking the sample is so small that the sampling site can be ground smooth. Secondly, the samples have to be extremely tiny and thin so that scientists can perform their studies using ions (i.e. charged atoms), which can only penetrate to a minimal depth into materials.

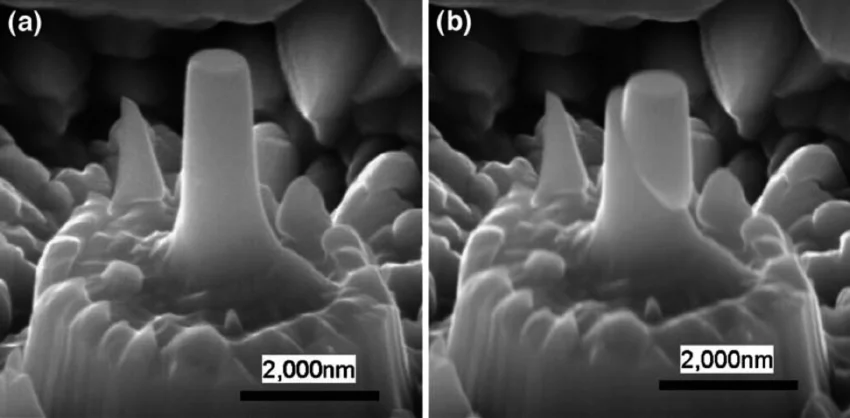

Basically, the scientists want to find out whether a material sample that was exposed to radiation behaves differently under stress compared with a sample that has not been exposed to radioactive irradiation. In the so-called micro- or nano-indentation technique used by materials experts, a sharp weight that has been precisely defined beforehand is pressed into the material to be studied, which is then analysed to see what the diagonals of the impression look like. If they are very short, the material is hard; if they are deep and wide, then it is soft. Alternatively, so-called micro-pillars may also be used, to which pressure is applied with a pressure stamp. These micro-pillars have a diameter of only 800 nanometres, making them about 150 times thinner than a human hair. Using this method, researchers can electronically apply a specified force in a controlled manner onto the stamp and at the same time measure the distance it travels. In this way, they are able to plot stress-strain curves, from which they can precisely determine whether the hardness of a material has changed under irradiation.

Modelling as a complement to measurement

Measuring and testing are one thing, but modelling and computer simulation are at least as important for a long-term prognosis. After all, future reactors should deliver energy reliably for 60 years or even longer. Engineers therefore have to know whether the materials they plan to use will remain stable throughout this period or may possibly become brittle.

To help them in their predictions, scientists work with micro-scale and thermodynamic calculations. Through the interplay of experimentation and modelling over different scales of time and space, it is hoped, for example, to find an answer to the question of what role magnetism plays in the processes. Expert opinion on this differs widely but the answer has a direct influence on the microstructure of the materials and their resulting mechanical properties. PSI has carried out precise calculations for the iron/chrome system. Studies have been carried out, for example, on how imperfections or defects form and move at the atomic level when exposed to radiation. Using the facilities available at PSI, scientists are able to immediately test their models in practice. Using X-ray light from the synchrotron Swiss Light Source SLS, for example, the formation and dynamics of domains of the same magnetization or geometric or chemical structure have been visualized in the iron/chrome system.

Under irradiation, size is not important

A sensational observation has been made by scientists at PSI in so-called ODS (oxide dispersion-strengthened) materials. These are commercial steel alloys that are suitable as construction material for the reactors of modern power plants. They contain the tiniest of ceramic inclusions – so-called dispersoids – of yttrium oxide, which usually measure a few nanometres in diameter. It is now known that, at high temperatures, the hardness of this steel increases in inverse proportion to the size of the inclusions. However, when the scientists performed the same experiments at high temperatures, but with radiation, they suddenly found that the size of the dispersoids no longer had any effect on creep resistance (resistance to deformation). No one expected this. On the contrary, industry had invested a great deal in incorporating the finest possible grain sizes within these alloys. It is now known that this is of no consequence at all, at least as far as the radiation-induced behaviour of the material is concerned.