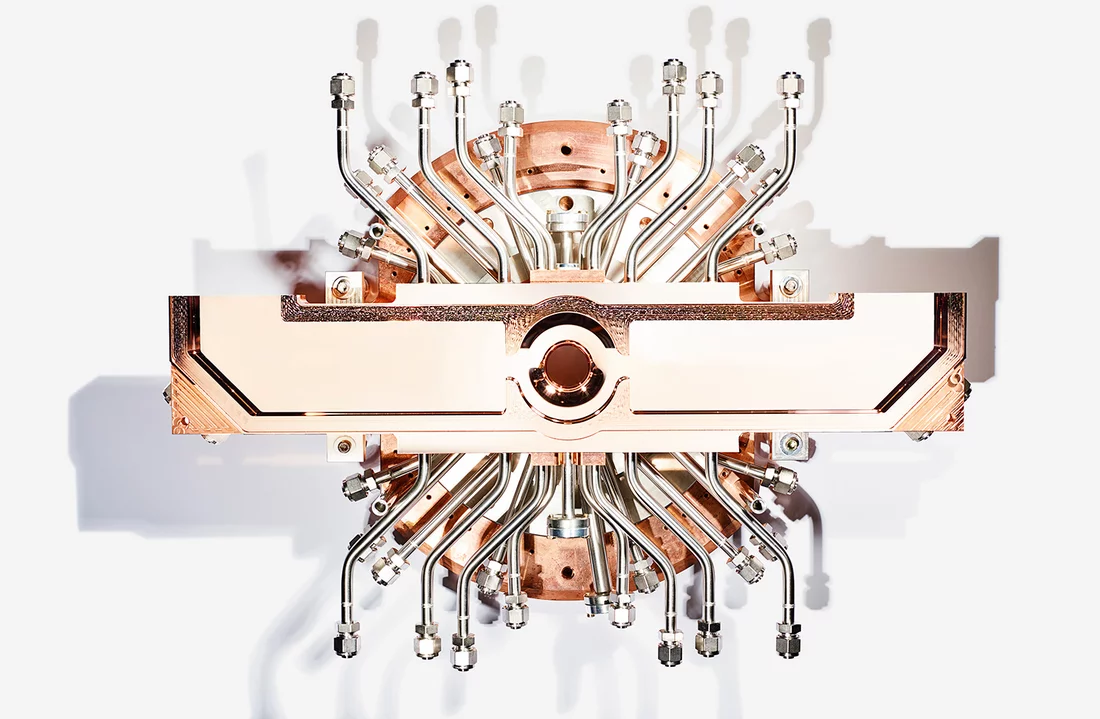

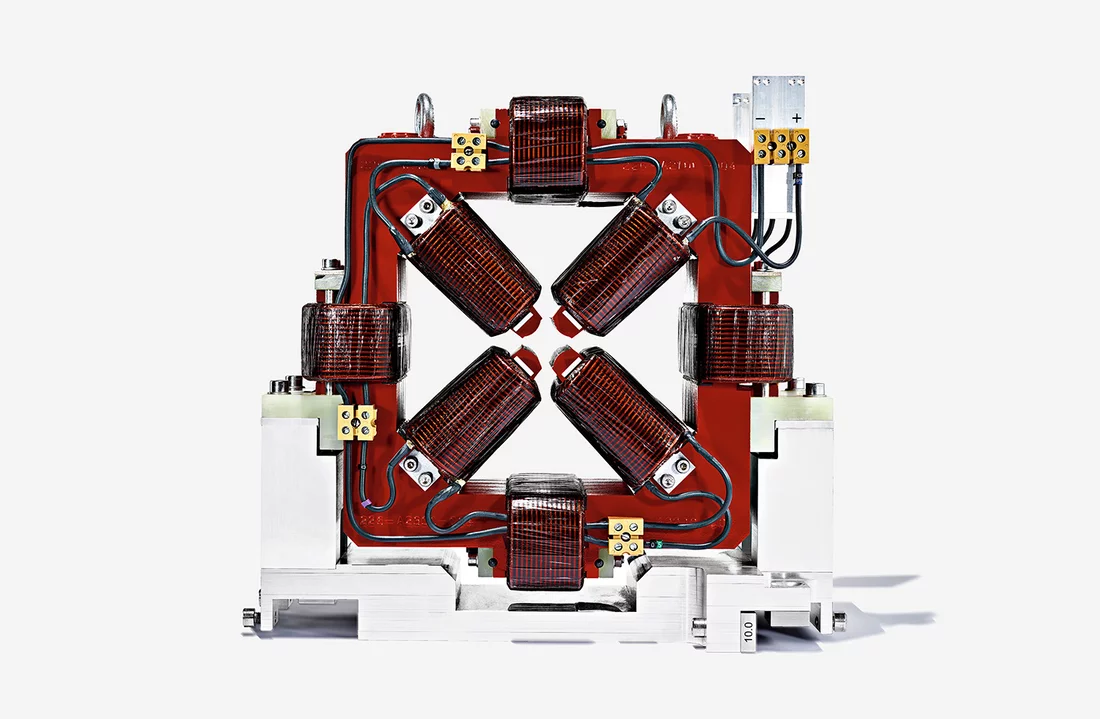

The art of engineering usually means mastery of the knowledge and skills required to design and manufacture devices that enable top technical performance. In five pictures, this gallery shows that the term can also be understood differently if the devices are regarded as works of art with their very own aesthetic, apart from their actual function.

Copyright

PSI provides image and/or video material free of charge for media coverage of the content of the above text. Use of this material for other purposes is not permitted. This also includes the transfer of the image and video material into databases as well as sale by third parties.