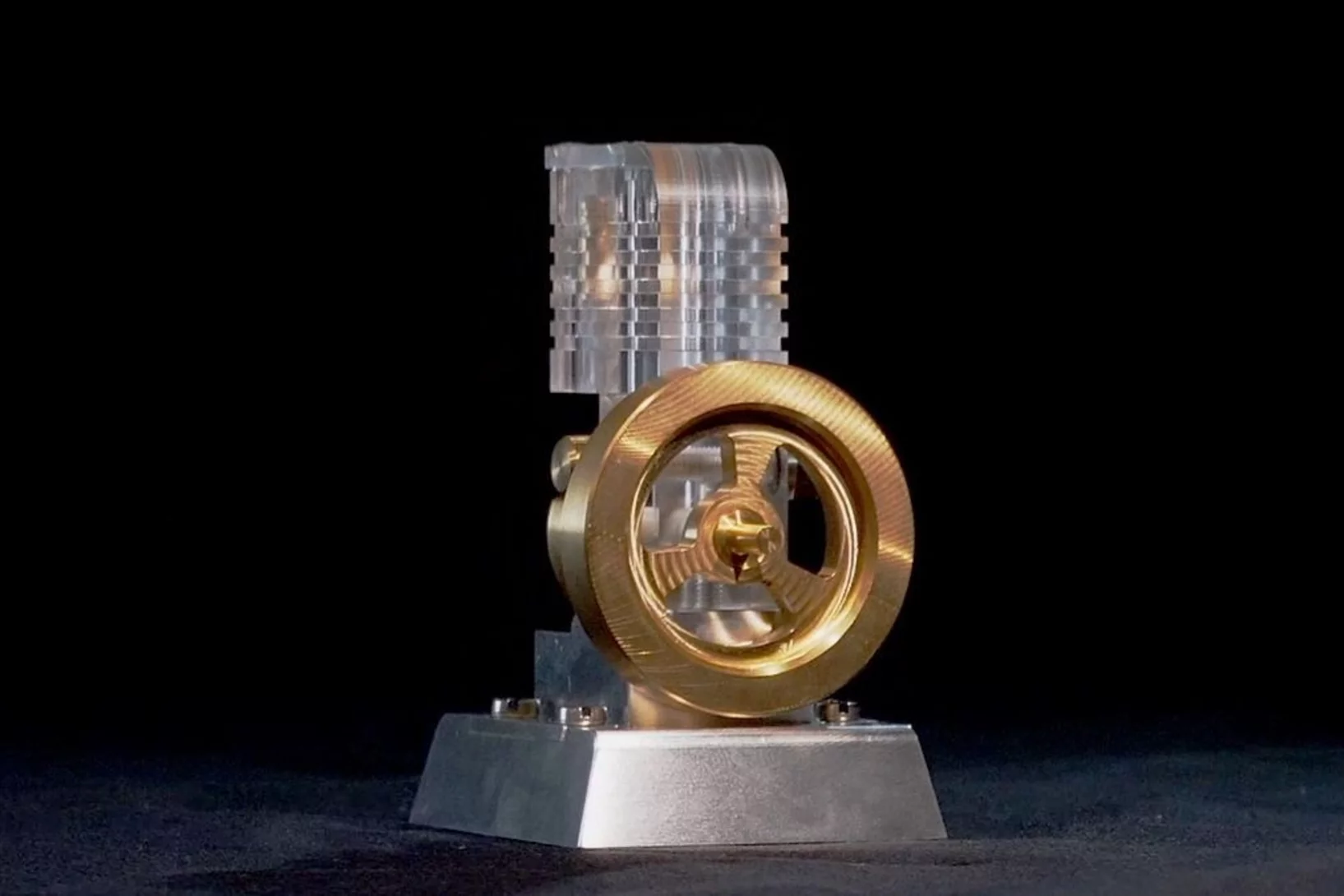

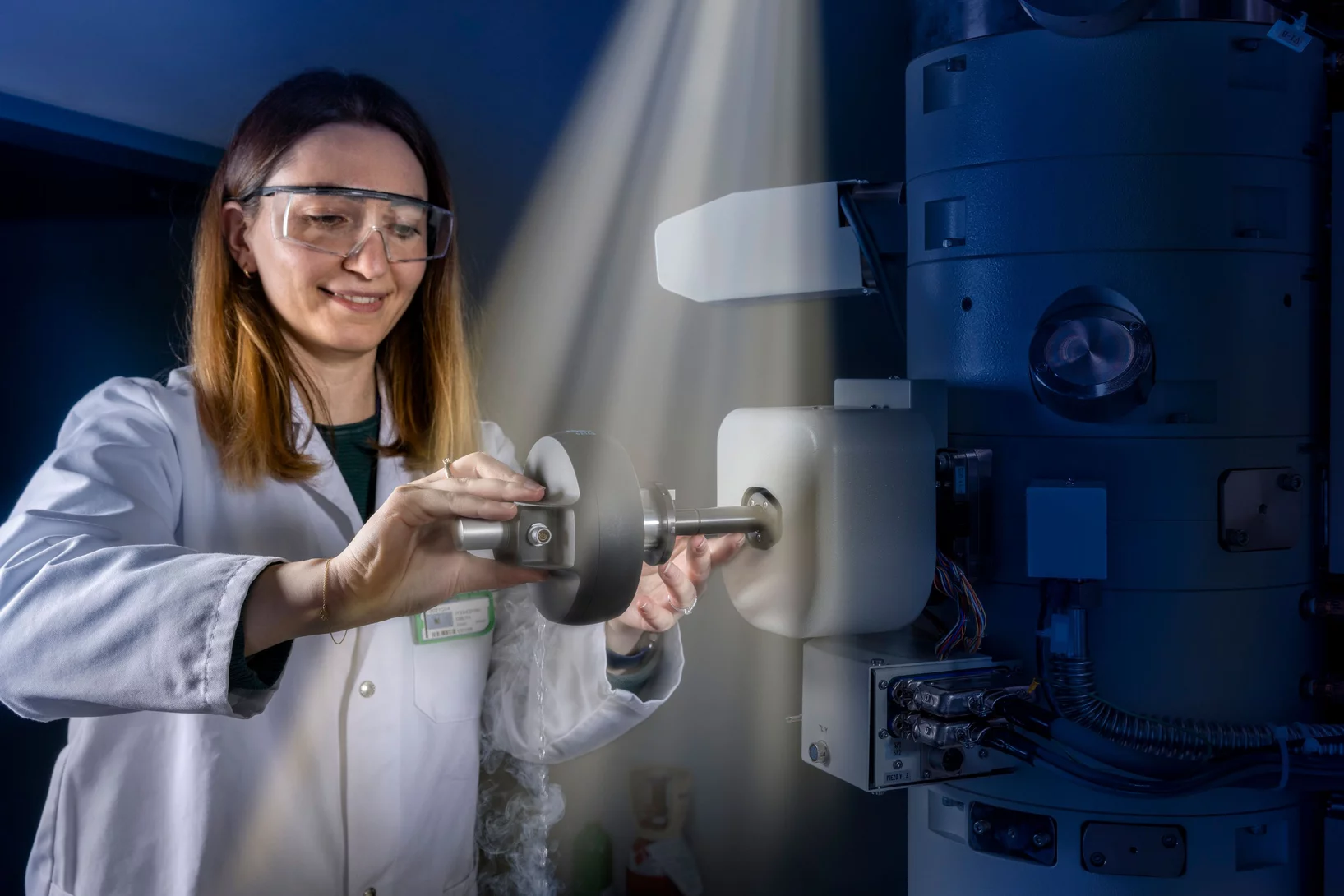

View into the beam tunnel of SwissFEL, where the X-ray light is generated. (Photo: Paul Scherrer Institute/Markus Fischer)

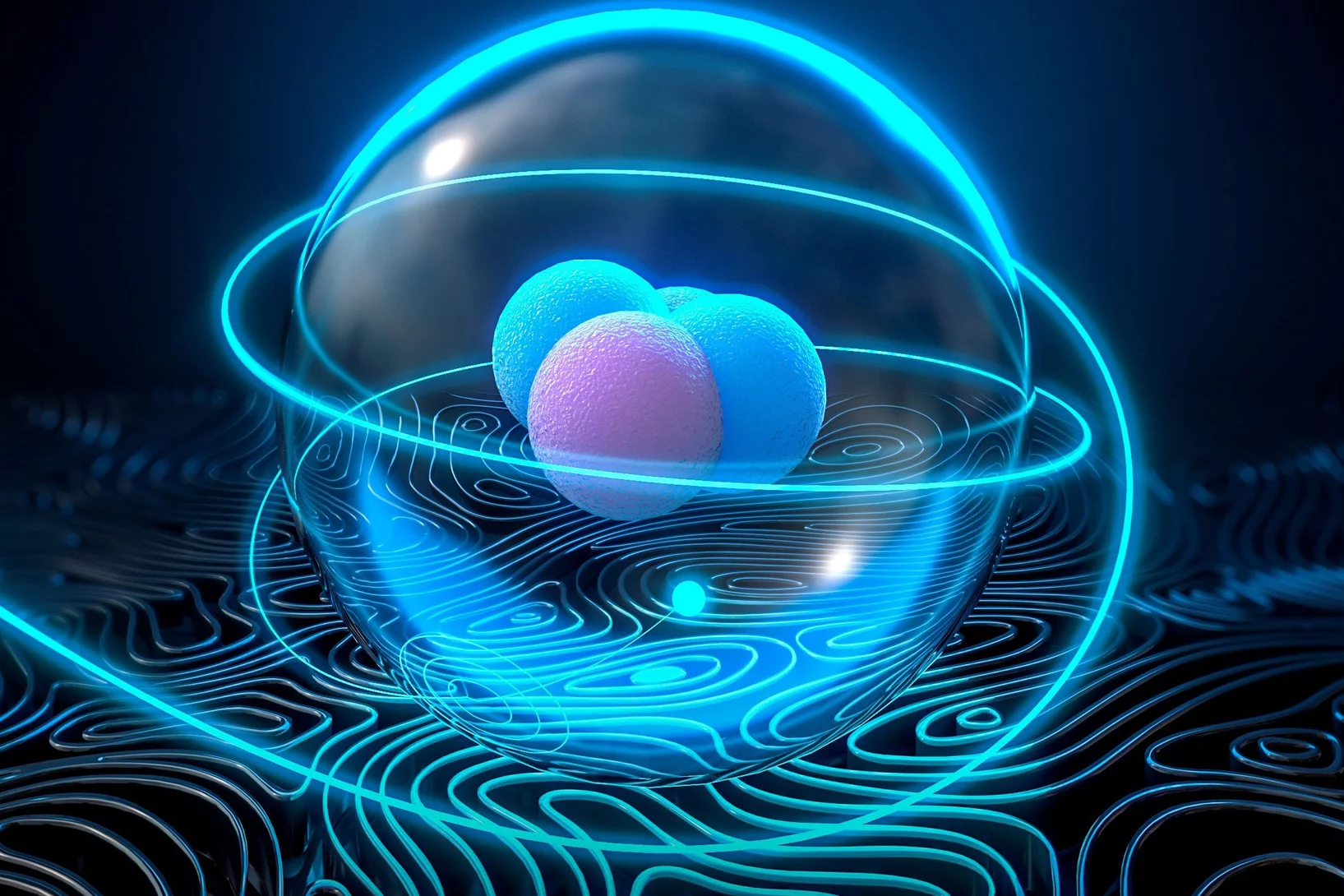

The latest large research facility at PSI generates very short pulses of X-ray light with laser-like properties. This enables researchers to observe extremely fast processes, such as how new molecules are created in a chemical reaction; to determine the detailed structure of vital proteins; or to determine the relationship between electronic and atomic structure in materials. This new knowledge expands our understanding of nature and leads to many practical applications, for instance new pharmaceuticals, more efficient processes in the chemical industry, or new materials for electronics.

Read more at: SwissFEL

Read more at: SwissFEL