Various basic materials for the chemical industry are manufactured using technology developed by the Ticino based company, Casale. The chemical compounds produced serve to make products like synthetic fertilisers or Plexiglas. In co-operation with PSI, Casale aims to make these production processes even more efficient as basic chemical products are export goods that face stiff competition around the globe. Tiny differences in production costs can be decicive when it comes to which licence a plant operator goes for.

Daily used products (generated in mass production processes) like synthetic fertilisers or Plexiglas have an impressive evolutionary process behind them. The base materials they are made from are usually manufactured under high pressure and at high temperatures — inside large chemical plants. Very often the starting product is natural gas. Techniques developed by the Ticino company, Casale, ensure that different basic materials are manufactured from the feedstock natural gas, which then undergo further processing (catalytic synthesis) into products like the synthetic fertilisers. Giacomo Colmegna, a qualified engineer with Casale, sums it up very simply, All our production processes are based on converting natural gas into useful products

.

Lugano-based Casale ranks amongst the biggest players worldwide when it comes to designing plants for the production of such basic materials. The company does not engage in any production work itself. It sells licences for the chemical processes on the basis of which other companies can then produce the necessary basic chemical materials like methanol, urea or ammonia. Together with the Paul Scherrer Institute, Casale wants to make these production processes even more efficient.

Industrial partners in the lab

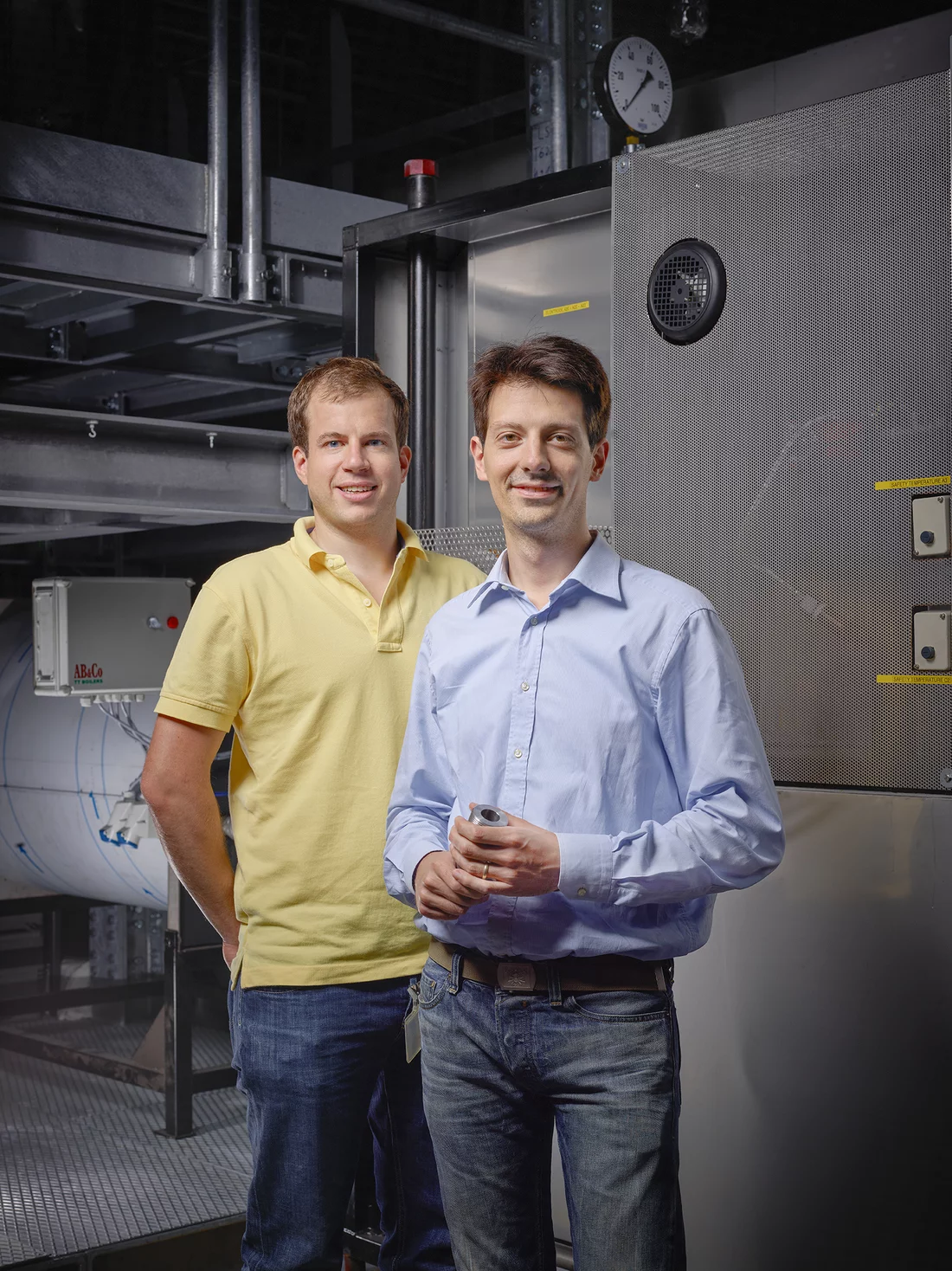

The industry for basic chemical materials has seen a trend for several years now towards bigger and bigger production capacities. But this trend is accompanied by a fundamental problem. The profitability and technical options of the methods developed today will reach their limits in the foreseeable future. Casale’s development department is working on processes that meet the growing requirements and it collaborates with the PSI Combustion Research Laboratory. For four years now Giacomo Colmegna has been accompanying the joint project on site. PSI is engaged in numerous projects in co-operation with industry. Nonetheless, the uninterrupted presence of an industrial partner in the lab over a period of this length is rare and testifies to the enormous importance of this co-operation for Casale.

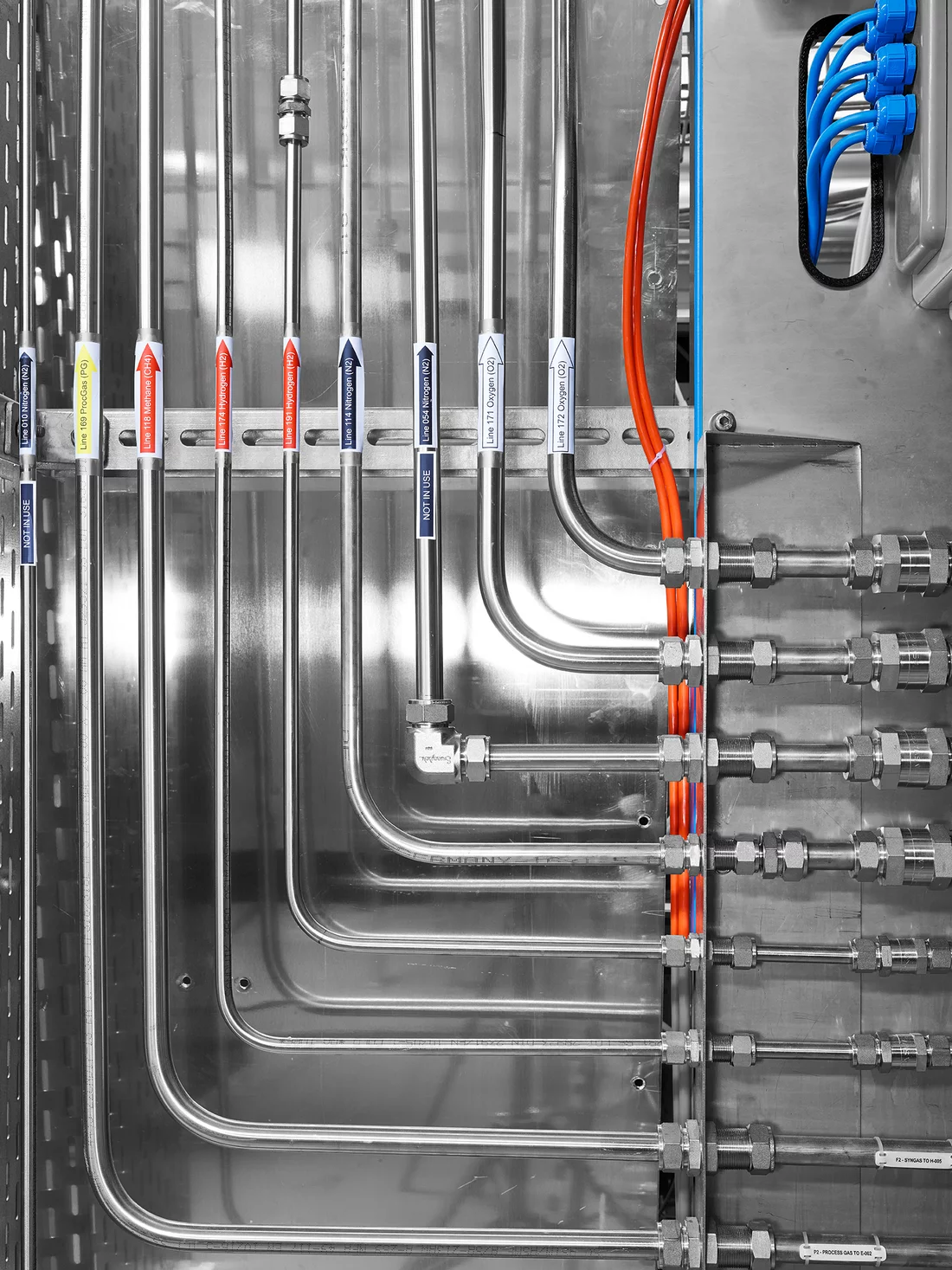

Casale did choose PSI firstly because it has facilities large enough to test the methods on an industrial scale. Secondly, the PSI researchers know how to measure the gas properties in the facility without any physical contact. Instead of inserting a thermometer or any other kind of probe into the facility, they measure the gas temperature or composition with a laser beam from outside. The measurement methods are complex but they have the advantage that they don’t influence the processes inside the facility.

Together with PSI, Casale is developing a method which increases production volume. To this end, the pressure in the facility is raised during the production process as the higher the pressure, the higher the mass flow of the materials produced using this method. This means that considerably more natural gas can be processed into basic materials during the same period in a plant of a given dimension.

Casale processes are already working at high pressure but only

up to 30 bar. Facilities that manufacture products using the previous method would have to be gigantic if they were to operate at 1 bar, i.e. at ambient pressure

, explains the PSI test engineer Markus Obrist.

At PSI a method using pressure of up to 100 bar is going to be tested. This corresponds to the pressure in the ocean at a depth of around one kilometre. The goal is to achieve stable processes and avoid undesirable by-products under this high pressure, too. Once the technology is functioning reliably, production could be increased by 50 percent. But the corresponding facility would only be 20 percent more expensive

, comments Colmegna confidently.

Stiff competition

This all sounds a lot simpler than it is. The plant components would need in particular thicker walls to withstand the enormous pressure and high temperature. Furthermore, the technology is more difficult to control under high pressure. Elevated pressure also impacts the chemical processes in the facility — and this not always in the desired manner. These influences must, therefore, be investigated thoroughly.

This is where PSI’s experience in this type of analysis comes in. Obrist explains, For instance more soot can form. This undesirable carbon would have a disruptive effect on the highly sensitive, downstream process stages. In this project we will determine whether and, if so, how undesirable accompanying materials are formed under higher pressures.

Various accompanying materials that occur naturally in natural gas may also have an effect and this must be examined, too.

Once the engineers have reliable data, they can start adapting the design of the commercial plant to the altered conditions. The goal is to achieve more efficient production compared with conventional methods. Basic chemical products are generally export goods that face stiff competition around the globe and thus, tiniest differences in production costs can be the match winner when it comes to which licence a plant operator goes for.

Text: Alexandra von Ascheraden