More effective control of diesel nitrogen oxides through dosed addition of ammonia

In diesel engines, the burning of the fuel releases nitrogen oxides (NOx), which are harmful to human health. The automobile industry therefore developed a technique that reduces these emissions: Gaseous ammonia is added to the exhaust and, prompted by a catalyst, reacts with the nitrogen oxides to produce harmless nitrogen and water. At low temperatures, however, this process does not yet work optimally. Now, for the first time, scientists at the Paul Scherrer Institute PSI have found a remedy which is based on observations at the molecular level: The precise amount of added ammonia needs to be varied depending on the temperature. With this knowledge, manufacturers can improve the effectiveness of their catalytic converters for diesel vehicles. The researchers have now published their findings in the journal Nature Catalysis.

To combat the noxious nitrogen oxides in diesel exhaust gas efficiently, the process must be continuously adapted to the changing exhaust gas temperature. This was discovered by PSI researchers investigating the so-called selective catalytic reduction (SCR) system.

SCR cuts the nitrogen-oxide emissions from diesel motors by up to 90 percent. This is accomplished by means of an additive known under the tradename AdBlue. The additive is injected into the exhaust where it decomposes into ammonia. With the help of a catalyst, the ammonia converts the noxious nitrogen oxides into harmless nitrogen and water.

However, SCR only delivers satisfactory results at exhaust temperatures well above 200 degrees Celsius. So from a cold start, it takes several minutes before the nitrogen oxides are optimally removed. For the same reason, SCR performance is also lower on cold winter days.

Understanding how reaction processes vary in time

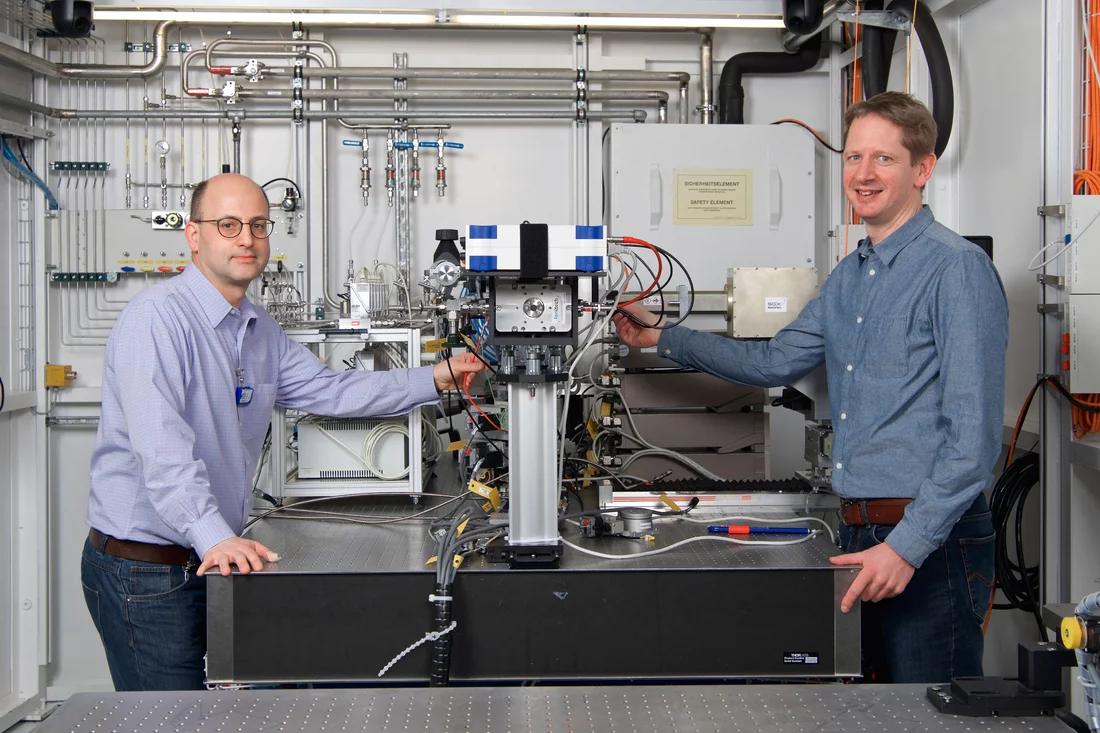

Still, why do the reaction processes run so differently under varying conditions? To find out, a research team at PSI studied the chemical processes in a copper-zeolite compound. They probed this catalyst material, which is used for example in the engines of passenger cars and light trucks, with X-ray light from the Swiss Light Source SLS. "Simply put, we illuminate the catalyst material with highly concentrated X-rays", explains PSI researcher Maarten Nachtegaal. "With that we can discern what happens during the reactions on the level of the copper atoms and the molecules bound to them."

The PSI researchers used a time-resolved spectroscopy method that has a crucial advantage over conventional methods: It shows the progress of the reactions instead of just providing snapshots. "Our temporal resolution here at SLS is nearly unique in the world", Nachtegaal points out. It is important to understand the temporal changes in the processes precisely because, for example, the exhaust temperature and the quantities of ammonia and nitrogen oxides going into the catalytic converter change continuously during a drive.

Amount of ammonia is crucial for lowering emissions

The most important insight from the newly conducted spectroscopy experiment: It is the ammonia itself that at low temperatures reduces the efficiency of the copper in the catalytic converter.

PSI researcher Davide Ferri summarises the conclusion: "Ammonia is necessary to remove the nitrogen oxides. But if too much ammonia is on hand, the catalytic converter can work only to a limited extent. So depending on temperature and operating conditions, different amounts of ammonia are required to achieve optimal removal of the nitrogen oxides."

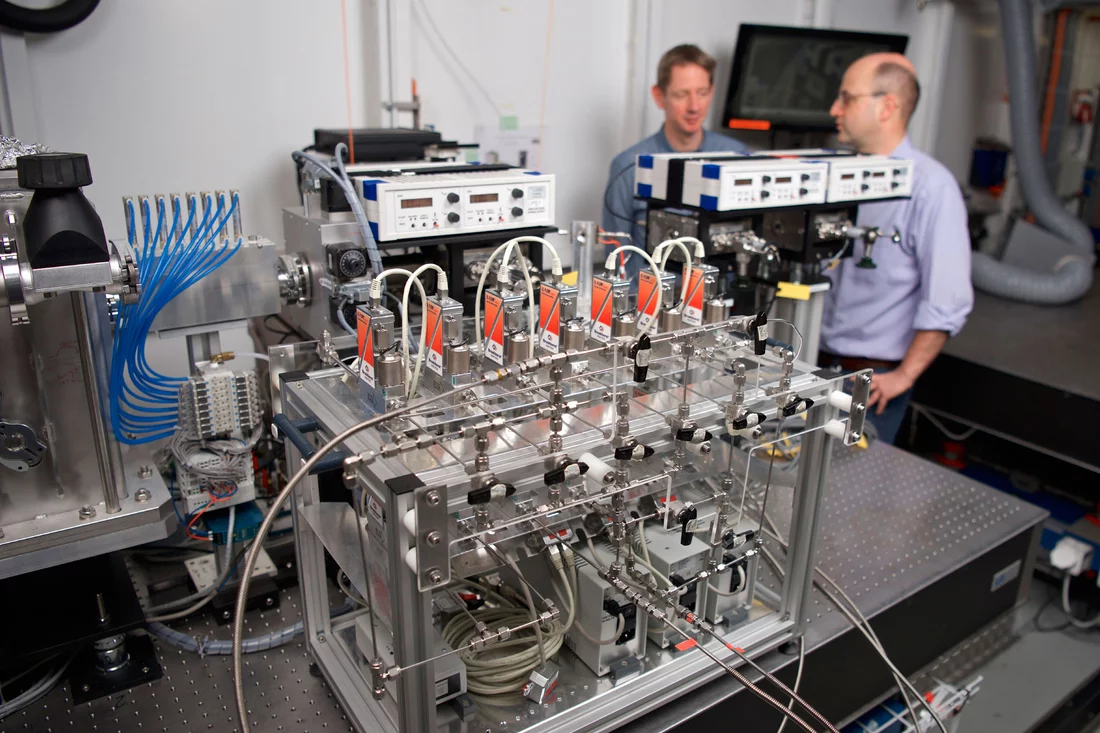

As a next step, on the basis of the insights they gained through spectroscopy, the researchers investigated the functioning of a copper-zeolite catalytic converter under realistic operating conditions: "In the laboratory, with changing temperatures, we fed in different amounts of ammonia and measured which dose of ammonia delivered the best result in each case", Ferri says. "With that, we were now able to say exactly, when the catalytic converter should receive how much ammonia to keep the nitrogen oxides in the exhaust as low as possible at all times."

Better air quality through optimised control of the catalytic converter

Nachtegaal sums up the result of the research project: "With our work, we have developed a better understanding of how the efficiency of catalytic converters for diesel vehicles can be increased." Thus the PSI researchers have shown the automobile industry a way to achieve clear improvements in urban air quality in the medium term.

Text: Paul Scherrer Institute

About PSI

The Paul Scherrer Institute PSI develops, builds and operates large, complex research facilities and makes them available to the national and international research community. The institute's own key research priorities are in the fields of matter and materials, energy and environment and human health. PSI is committed to the training of future generations. Therefore about one quarter of our staff are post-docs, post-graduates or apprentices. Altogether PSI employs 2100 people, thus being the largest research institute in Switzerland. The annual budget amounts to approximately CHF 380 million. PSI is part of the ETH Domain, with the other members being the two Swiss Federal Institutes of Technology, ETH Zurich and EPFL Lausanne, as well as Eawag (Swiss Federal Institute of Aquatic Science and Technology), Empa (Swiss Federal Laboratories for Materials Science and Technology) and WSL (Swiss Federal Institute for Forest, Snow and Landscape Research).

(Last updated in May 2017)

Additional information

Diesel particle filter and nitric oxide catalyst all rolled into oneCurrent PSI research on the topics of energy and environment

Contact

Dr. Davide Ferri, Catalysis for Energy Group, Laboratory for Bioenergy and CatalysisPaul Scherrer Institute, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 27 81, e-mail: davide.ferri@psi.ch [German, English, Italian]

Dr. Maarten Nachtegaal, Group Head In situ X-Ray Spectroscopy, Laboratory for Bioenergy and Catalysis

Paul Scherrer Institute, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 30 56, e-mail: maarten.nachtegaal@psi.ch [German, English, Dutch]

Original Publication

Time-resolved copper speciation during selective catalytic reduction of NO on Cu-SSZ-13A. Marberger, A. W. Petrov, P. Steiger, M. Elsener, O. Kröcher, M. Nachtegaal, D. Ferri

Nature Catalysis, 8 March 2018 (online),

DOI: 10.1038/s41929-018-0032-6