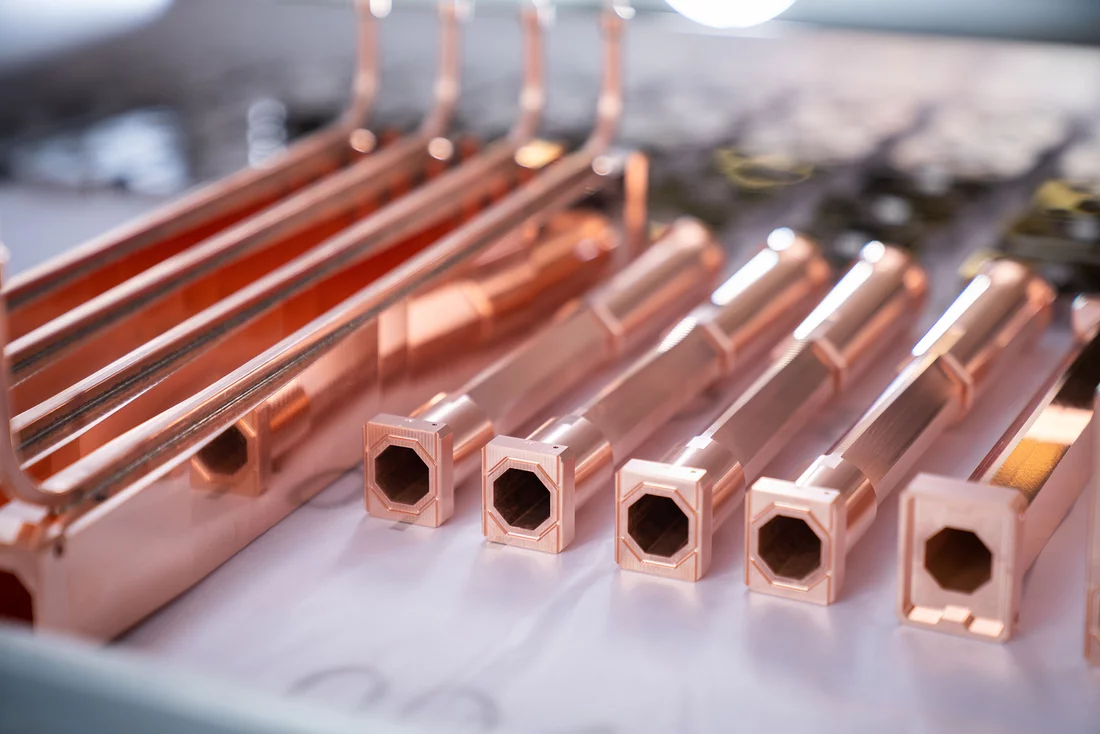

How the parts of the future vacuum tube are made from copper: René Sieber and Romain Ganter show how the chambers are built through which the electrons will race after the SLS 2.0 upgrade. A three-part creation account.

The crux is the diameter. The internal diameter of the future vacuum tube for the Swiss Light Source SLS is just 1.8 centimetres. And the external diameter is scarcely any larger, because the walls are to be just one millimetre thick. This narrow tube will form a large ring with a circumference of 288 metres. That will be the home of the electrons, a place where they will race around and around in circles at almost the speed of light. In the process, they will generate synchrotron radiation, which in turn will be used for research.

To understand why the new tube has to be so narrow and thin and how this technical feat is accomplished, it is worth visiting several PSI sites: the workshop on the PSI site east of the Aare; a multi-purpose hall on the western PSI site; and the SLS building itself.

René Sieber and Romain Ganter have suggested starting in the workshop. “It was about four years ago that we first started discussing how to tackle the technical challenges of the new vacuum ring,” Ganter recalls.

He and Sieber are both members of the PSI’s Division of Large Research Facilities. René Sieber is a technician and head of the Production Technology Section. The workshop is his domain. Romain Ganter has a scientific background: a trained physicist, he is head of the Vacuum Section and also responsible for upgrading the electron storage ring in the SLS 2.0 project. The central piece of this is the vacuum tube.

“We soon realised that this was going to be a complex business. So it made sense to consider building it ourselves. Or at least to start with our own prototype,” adds Sieber.

Lack of space between the magnets

Ganter’s team came up with the first design for the tube. Having said this, no one at PSI calls it a tube: these are vacuum chambers that, when joined together, will form the hollow vacuum ring. They are planning to have a total of 500 vacuum chambers. The chambers are by no means all identical, because every segment along the electron storage ring must be specifically adapted to the conditions at that point. Every centimetre is accounted for: with magnets to guide the electrons accurately; with undulators – specially arranged magnetic elements – to specifically excite the electrons to produce synchrotron radiation; with diagnostic elements to measure all the relevant parameters; with elements for water cooling; with vacuum pumps; and so on.

The vacuum chambers have to fit in between all these different elements. Because of this, their cross-section is not actually circular, but in most places is shaped like an octagon. “That way, our magnets and measuring instruments fit around them very nicely,” says Ganter. The magnets, in particular, are to be moved as close as possible to the electron beam for the upgrade, enhancing it to produce more brilliant synchrotron radiation.

Haggling over fractions of a millimetre

That is in fact precisely why the vacuum chambers are only 1.8 centimetres in diameter. Everything has to be manufactured with extreme precision: in some cases, the tolerance may only be 0.01 millimetres. Wherever possible, the designers haggled over fractions of a millimetre, including the thickness of the walls. The restrictions imposed on the outer dimensions meant that the material could only be made thicker on the inside. But that would leave even less room for the electrons and the air inside would be even harder to extract than is already the case – not ideal if the aim is to create an ultra-high vacuum to prevent the electrons from colliding with air molecules.

Talking about material, Sieber, the technician, specifies: “Most of the chambers are made of high-purity copper.” This is not the case with the SLS vacuum ring that went into operation in 2001; those chambers are made of stainless steel. This is cheaper and much easier to work with. “But in view of the small diameter, we absolutely had to use a material that was a good conductor of both electricity and heat,” explains Ganter, the physicist. Copper fulfils both these requirements. “A so-called mirror current forms in the walls, and this must be able to flow alongside the electrons easily so as not to slow them down in the storage ring. And the thermal conductivity is important so that we can cool the chambers; because the synchrotron radiation generates quite a bit of heat.”

The copper pushed the technicians to the limits of what was achievable. But they rose to the challenge. All 500 vacuum chambers were planned at PSI. The 100 most complex ones are also being built here, in the workshops. The remaining 400 were contracted out by PSI to external suppliers, who were given detailed instructions.

Text: Paul Scherrer Institute/Laura Hennemann

Read about how the vacuum chambers are made at PSI in Part 2, as from 15.06.2023.

Contact

René Sieber

Large Research Facilities Division, head of the Production Technology Section

Paul Scherrer Institute PSI

+41 56 310 54 19

rene.sieber@psi.ch

[German]

Dr. Romain Ganter

Large Research Facilities Division, head of the Vacuum Section

Paul Scherrer Institute PSI

+41 56 310 52 79

romain.ganter@psi.ch

[German, English, French]

Further information

SLS 2.0 - The upgrade of the Swiss Light Source SLS

Copyright

PSI provides image and/or video material free of charge for media coverage of the content of the above text. Use of this material for other purposes is not permitted. This also includes the transfer of the image and video material into databases as well as sale by third parties.