The Zurich-based power company Energie 360° provides natural gas, biogas, and wood pellets throughout Switzerland. Now, with the Paul Scherrer Institute PSI, it has successfully tested a new Power-to-Gas technology to be implemented in the area of biogas production. The joint project was awarded the Swiss energy prize Watt d'Or 2018. In this interview, division manager Peter Dietiker talks about the collaboration with PSI.

5232: Mr. Dietiker, the cooperation between your company Energie 360° and PSI has not been going on all that long – yet there is already a first result to report: a thousand-hour test of a jointly developed technology under realistic conditions. Was the test successful?

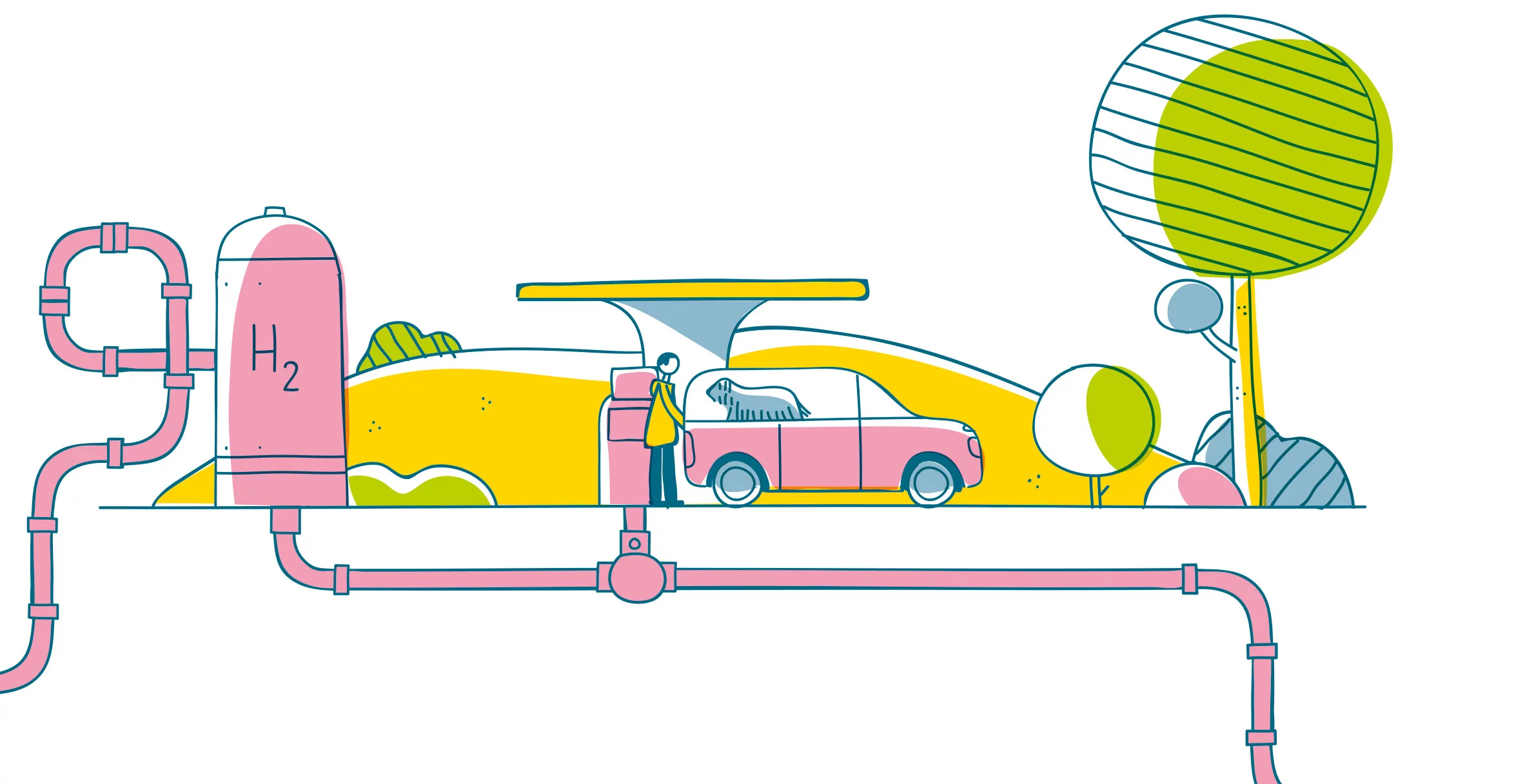

Peter Dietiker: Absolutely! The project you're talking about is called Cosyma: Container-based System for Methanation. This container thing is typical for PSI's ESI test platform: All the laboratories and systems there are modular, and these modules – which actually are housed in classic shipping containers – are accordingly easy to transport. Cosyma is a system that can produce 60 percent more renewable natural gas – that is, biogas – from the same amount of biowaste than the conventional biogas technology. To do that, Cosyma uses hydrogen that has been generated, under favourable weather conditions, with the help of surplus renewable electric power. So in the end, part of the energy in this biogas comes from the sun and the wind.

And how did it go with the practical test of Cosyma?

In January 2017, the Cosyma container came from PSI to Biogas Zurich, which operates a biogas plant at the Werdhölzli wastewater treatment site. We have been producing biogas from biowaste and sewage sludge there for four years now. This can be used in exactly the same way as conventional natural gas and, accordingly, is fed into the normal gas network. On the Werdhölzli site, we positioned the Cosyma container next to the standard system there for biogas processing and diverted a portion of the incoming gas into the Cosyma container. At the back end, the new kind of biogas produced by Cosyma was fed into the gas network together with the classical biogas. And there it became clear during one thousand hours of operation: The Cosyma technology works, and it works well and reliably. Today, from the standpoint of cost-effectiveness, gas production with the new Cosyma technology is not yet better than with the existing method, but that was just a test with a prototype – so we are confident about its future.

Cost-effective – that is a typical expression of the business mindset. Do the researchers think very differently? Where did you need to come together?

Naturally, the researchers have a completely different background, and that's a good thing – otherwise we wouldn't need each other. For example, the PSI researchers asked if we really wanted to do a thousand-hour test, since a hundred hours would be sufficient. But for us, coming from the practical side, it was important to do exactly this kind of long-term test. And as a bonus, we were able to give a lot of visitors a live demonstration during those thousand hours.

Is there also an example the other way around?

Yes, in matters of quality it was the other way around: There it was the researchers who wanted to achieve even more than we did. Clearly, the researchers' ultimate goal was a gain in understanding. And often, in the course of a project, you stumble on something different that also could be investigated further. In our business world, however, that can't be permitted as it puts a burden on costs and scheduling. We have no interest in exceeding the quality that's required. That would be like if you ordered a new kitchen, and the craftspeople came in and installed something more than you wanted and then demanded a correspondingly higher price. In precisely this sense, we initially wanted the researchers to do only what we'd ordered. But with Cosyma, we couldn't prevent the researchers from helping us gain more insights than originally planned, and thus exceeding our expectations! (He smiles.)

The Cosyma project was just awarded the Watt d'Or 2018 by the Swiss Federal Office of Energy, in the Renewable Energy category. How will things go forward now with this technology?

We have helped to bring research on this new technology to the point where the knowledge is now there and publicly available. The next step will be industrialisation through a plant manufacturer. We and the PSI researchers are already in discussions with potential implementation partners, and I expect that somewhere, sometime within the next five years, the first commercial plant with the Cosyma technology will be built. We at Energie 360° can well imagine buying and installing such a commercial plant then ourselves. With this, we would be able to offer our customers biogas that makes even more optimal use of the natural resources. Then it would not be exclusively a question of cost-effectiveness, but also a matter of ecology, which is of interest to us as well as our customers.

Interview: Paul Scherrer Institute/Laura Hennemann

About Peter Dietiker

Peter Dietiker is head of the Renewable Energy Division at Energie 360°. Educated as a business economist, he has worked in the field of energy and water supply for 25 years, for the past 15 years at the company Energie 360°. Here, since 2009, he has successfully built up and expanded the renewable energy area with biogas and wood pellets.

Additional information

Using what's there: A background article which shows how researchers at PSI are looking for solutions that enable energy from the sun, the wind, or biomass to be efficiently integrated into the Swiss energy system.

Profitable for both sides: An interview with Alexandre Closset, CEO of Swiss Hydrogen, about the collaboration with PSI.