Researchers from the Paul Scherrer Institute (PSI) have showcased a solar-thermal method for extracting zinc oxide, a technologically important reusable material, from zink recycling products under laboratory conditions. The solar product’s purity level exceeds that obtained via the industrially established route.

Zinc is one of the most important reusable materials of the modern world: found in a wide range of products as a component of brass and bronze, it is also increasingly in demand in the cosmetics and food industry. The majority of global zinc production, however, is used for corrosion protection: every year, millions of tons of steel are zinc-coated to make it weather-proof, such as for vehicle bodies.

This also means that steelworks are the main source of secondary raw materials (i.e. not from mineral ores) for the production of zinc. Up to 35 per cent of the filter dust that accumulates while recycling galvanised steel in electric arc furnaces is zinc. As it contains various heavy metals, this dust is classified as hazardous waste and therefore has to be disposed of in special repositories or disposal sites. High disposal costs and stricter environmental regulations have increasingly challenged the disposal of waste dust, which is also questionable from a resource conservation perspective. Meanwhile, however, around 40 per cent of the 7 million tons of electric arc furnace dust accumulated every year is processed further for the purposes of zink recovery instead of being deposited.

The industrially established procedure

The so-called Waelz method has established itself as the most common way to recover zinc oxide from this filter dust. First, the zinc oxide from the waste dust is reduced to zinc via a reaction with carbon in a rotary kiln at temperatures of around 1,200 degree Celsius. At these temperatures, zinc is gaseous before being oxidised again through the subsequent reaction with the oxygen present in an injected air stream. The resulting dust-like product is referred to as Waelz oxide. Although raw Waelz oxide is 70 to over 75 per cent zinc oxide, due to the relatively high levels of chlorine, fluorine and lead compounds it is still contaminated. As many industrial applications require a purer oxide, however, some of the chlorine and fluorine impurities are washed out of the crude Waelz oxide in an additional step. Washed Waelz oxide attains zinc oxide levels of over 80 per cent while the unwanted chlorine and fluorine parts are forced below 0.1 or 0.15 per cent.

Alternative path to even purer zinc oxide

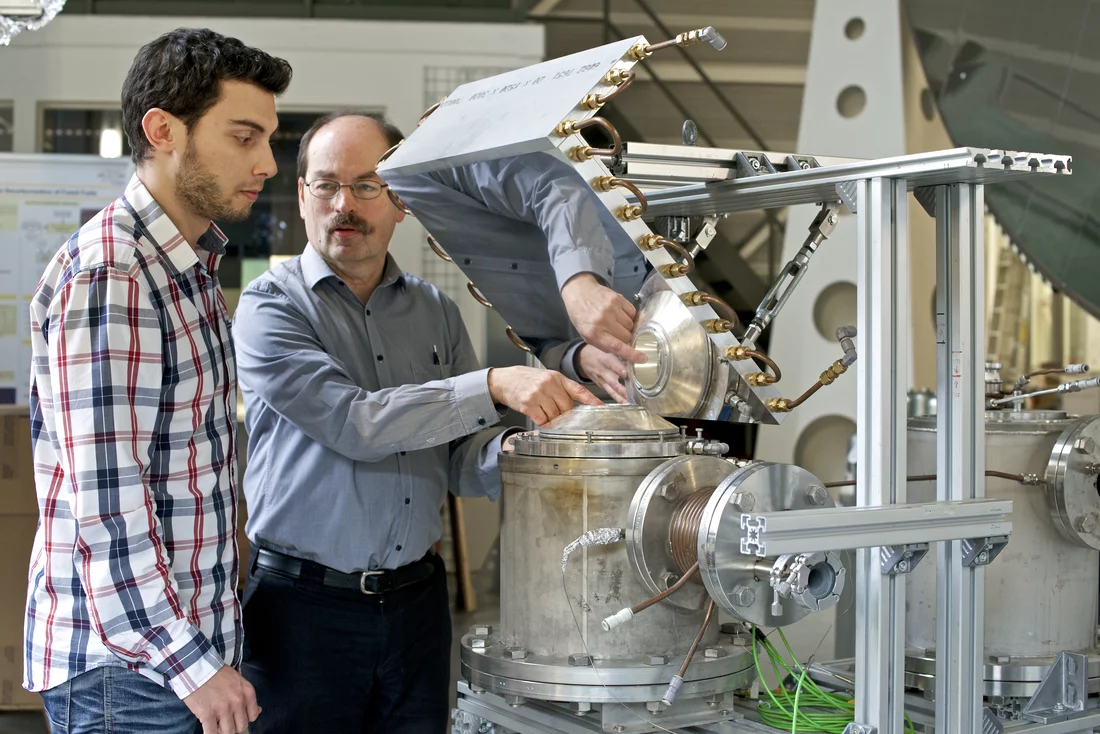

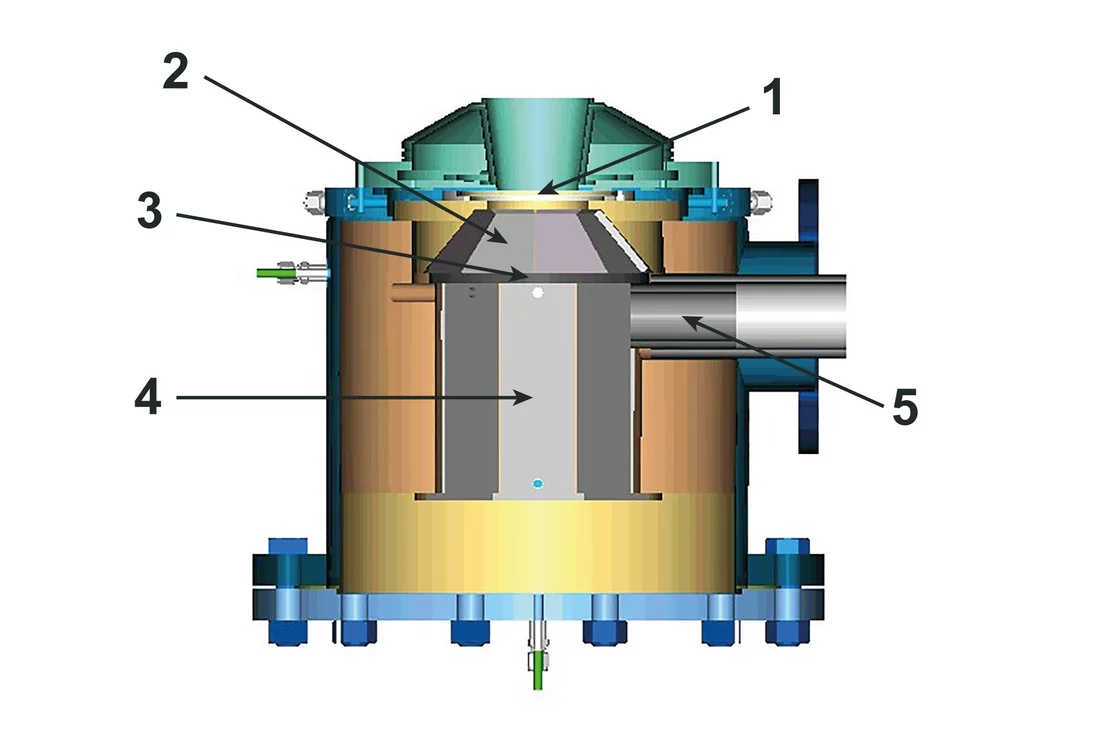

PSI researchers have now demonstrated a solar-thermal route for the purification of Waelz oxide under lab conditions. The project was carried out in collaboration with researchers from the University of Leoben in Austria and industrial partner Befesa Steel AG. The base material was crude (i.e. unwashed) Waelz oxide. The oxide to be purified was processed in a solar reactor, which was heated with concentrated radiation from the PSI’s own high-flux solar simulator, in which ten xenon lamps serve as the radiation source. With the aid of mirrors, the xenon-lamp light is concentrated to several thousand times the solar radiation density that reaches Earth. Exposed to the concentrated radiation from five of these artificial suns, the Waelz oxide was heated to 1,300 degree Celsius in order to evaporate off the undesired lead and chlorine compounds, thereby purifying the Waelz oxide.

Drastic reduction in the lead content

The result of this “solar clinkering” was a success: better zinc oxide was produced from the crude Waelz oxide than that obtained through conventional industrial washing. In particular, the proportion of undesired lead plunged to under 0.1 per cent compared to around 5 per cent in the washed Waelz oxide. Successful lead reduction is especially relevant when it comes to processing zinc oxide further into zinc as the electrolytic procedure used industrially does not handle even minor concentrations of lead very well. The solar-enhanced zinc oxide could also be reduced to zinc in the solar reactor via a reaction with carbon. Incidentally, the PSI scientists have already studied this so-called solar carbothermal reduction in detail in another research project (http://www.psi.ch/lst/solzinc).

Text: Leonid Leiva

Contact

Dr. Christian Wieckert, Laboratory of solar technology, Paul Scherrer Institute,Telephone: +41 56 310 44 07, E-Mail: christian.wieckert@psi.ch

Original Publication

Thermal recycling of Waelz oxide using concentrated solar energyN. Tzouganatos, R. Matter, C. Wieckert, J. Antrekowitsch, M. Gamroth, A. Steinfeld

JOM : Vol. 65. no. 12, Dec. 2013

DOI: 10.1007/s11837-013-0778-x

Related article

14. January 2013

The sun rises for cement

Cement holds the world’s buildings together. The binding agent for concrete and other construction materials is, if assessed by global production volumes, one of the world’s most important assets. However, cement production consumes vast amounts of energy – and this is largely obtained by the combustion of fossil fuels. Scientists at the Paul Scherrer Institute and the globally-active Swiss cement manufacturer Holcim want to change this.