In a collaboration with DESY in Hamburg, Germany, we have developed additive manufacturing processes based on 2 photon 3D lithography for fabrication of X-ray optical components that offers high quality and greatly enhanced flexibility in optics design compared to established techniques. Two-Photon 3D Lithography as an additive process has shown the viability of manufacturing various types of X-ray optics and special purpose objects with high precision. Several optics have been developed with and successfully used at Synchrotron Radiation as well as Free Electron Lasers facilities.

Polymer Compound Refractive Lenses

Refractive X-ray lenses are used in many synchrotron radiation applications, e.g. for the creation of nanoscale beams for scanning techniques. The low refractive power of all lens materials introduces the need for very small radii of curvature, which complicates fabrication. Refractive lenses made from silicon, beryllium, aluminum or SU-8 have been reported, all with their individual advantages.

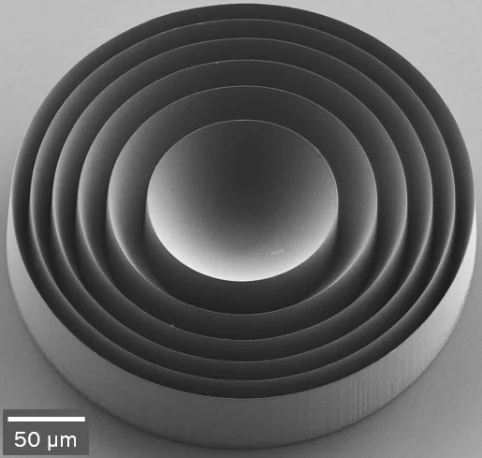

An example of a refractive lens made by 2 photon polymerization is shown in figure 1. The lens consists of three parabolic refractive surfaces, each with an apex radius of 3 µm, which results in a focal length of 240 mm at 8.2 keV. The beam caustic is calculated from the illumination function determined by a ptychographic scan and shows small sidelobe intensity. Propagation of the wavefront to the exit of the lens confirms aberrations to be significantly smaller than typically found e.g. in Be lenses.

Publications

- M. Lyubomirskiy, F. Koch, K.A. Abrashitova, V.O. Bessonov, N. Kokareva, A. Petrov, F. Seiboth, F. Wittwer, M. Kahnt, M. Seyrich, A.A. Fedyanin, C. David, and C.G. Schroer. Ptychographic characterisation of polymer compound refractive lenses manufactured by additive technology, Optics Express 27 (2019) p. 8639-8650

Multibeam Compound Refractive Lenses

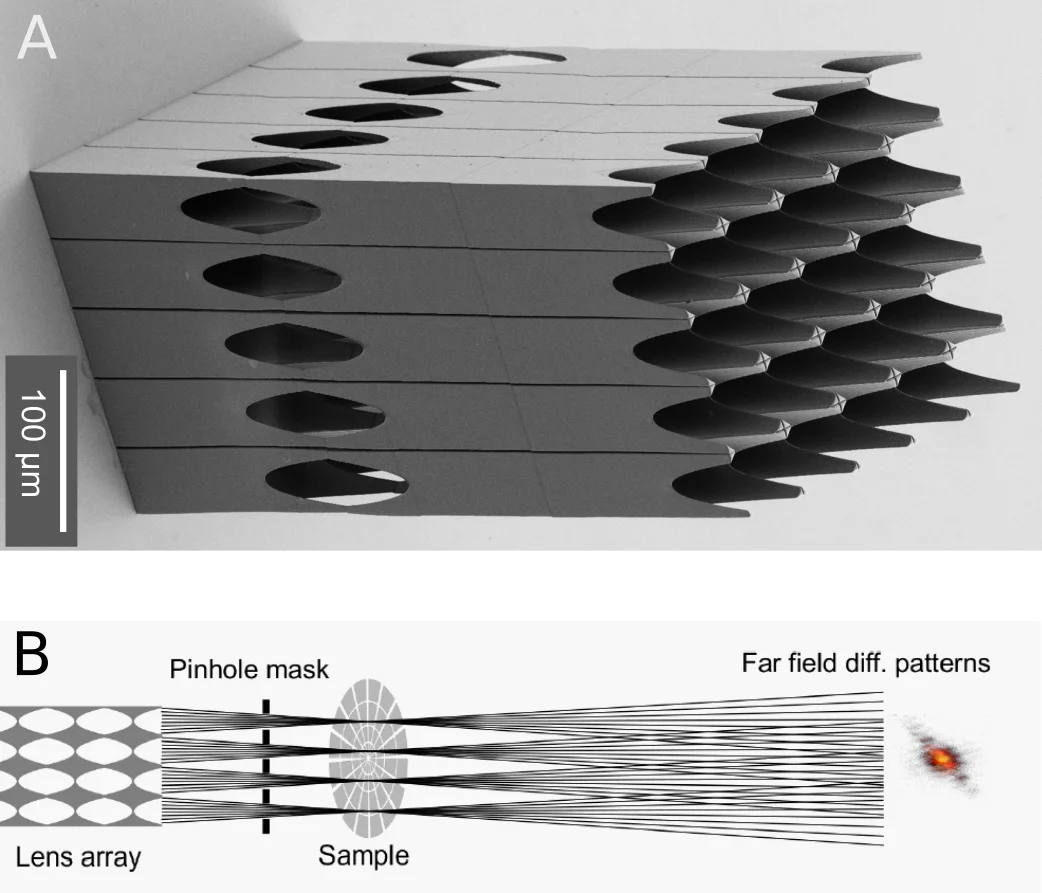

One example of optics with advanced optical properties is an array of compound refractive lenses we have manufactured for use at PETRA III. The array can be used together with a pinhole mask to produce several focal spots on a sample at once. This can be used for scanning a larger area on a sample in a similar time as with one single lens.

Figure 2 shows an example of an array of 25 lens towers with an aperture of 45 µm and three refractive surfaces each; the apex radius is 2.5 µm. The structure has a total height of 450 µm. Evan taller structures with heights in the mm range are also possible with vertical stitching.

Kinoform Refractive Lenses

For optics with larger apertures the height of increases significantly. For such lenses it is therefore possible to manufacture kinoform type lenses. Such lenses have a jump if the height approaches the phaseshift of 2 Pi. Figure 2 shows a Kinoform lens with an aperture of 300 µm and an apex radius of 40 µm with a resulting structure height of 47 µm. This results in a focal length of 14 meter at an X-ray energy of 10 keV.

Phase Correction

Further applications include the phase correction for imperfect X-ray optics. An example are widely used Beryllium CRLs; due to the manufacturing process the resulting surface has small but systematic deviations of the perfect shape. In order to obtain desired focusing properties many lenses are stacked and thus the resulting beam inherits the phase imperfections of all lenses. Therefore, the focused beam might not be diffraction limited due to the aberrations. The phase error can be obtained for example by performing ptychography and analysing the reconstructed probe. Based on this information the shape of a corrective phase plate can be calculated.

Similar wearing glasses a the calculated corrective phase plate can be added as an optical element in the beam path to improve the optical properties.

3D Printing with Two-Photon Lithography can be used to manufacture almost arbitrary shapes and is therefore perfectly suited to manufacture corrective phase plates. Figure 4 a) shows an SEM image of a phase plate and b) and c) show a reconstruced caustics without and with the corrective phase plate, respectively. An almost diffraction limited focus can be achieved, the aberrations are significantly reduced and the flux in the focus is increased significantly.

M. Seaberg, R. Cojocaru, S. Berujon, E. Ziegler, A. Jaggi, J. Krempasky, F. Seiboth, A. Aquila, Y. Liu, A. Sakdinawat, H. J. Lee, U. Flechsig, L. Patthey, F. Koch, G. Seniutinas, C. David, D. Zhu, L. Mikeš, M. Makita, T. Koyama, A. P. Mancuso, H. N. Chapman and P. Vagovič (2019). Wavefront sensing at x-ray free-electron lasers. Journal of synchrotron radiation, 26(4).

F. Seiboth, D. Brückner, M. Kahnt, M. Lyubomirskiy, F. Wittwer, D. Dzhigaev, T. Ullsperger, S. Nolte, F. Koch, C. David, J. Garrevoet, G. Falkenberg and C. G. Schroer (2020). Hard X-ray wavefront correction via refractive phase plates made by additive and subtractive fabrication techniques. Journal of synchrotron radiation, 27(5).

Falkenberg, G., Seiboth, F., Koch, F., Falch, K. V., Schropp, A., Brückner, D., & Garrevoet, J. (2020). CRL optics and silicon drift detector for P06 Microprobe experiments at 35 keV. Powder Diffraction, 1-4.

Phase Manipulation

For advanced optical properties there are virtually unlimited possibilities to print various types of optics. X-ray beams can be manipulated by making appropriate optics.

One example for are vortex phase plates. An example for a three step vortex phase plate is shown in Figure 5. By increasing the phase shift along the azimuthal direction with an increasing height of the structure the resulting beam inherits a topological charge. The topological charge depends on the number of steps in the phase plate. Also this type of optics is added as an additional optical element into an optical setup.

By designing other types of phase manipulation phase plates specific types of beam properties can be achieved as well.

F. Seiboth, M. Kahnt, M. Lyubomirskiy, M. Seyrich, F. Wittwer, T. Ullsperger, S. Nolte, D. Batey, C. Rau, and C. G. Schroer (2019). Refractive hard x-ray vortex phase plates. Optics letters, 44(18), 4622-4625.