In several laboratories at the Paul Scherrer Institute PSI, researchers work with radioactive substances that eventually should aid in the diagnosis and treatment of cancer or metabolic diseases - but where do you go for substances that decay in just a few hours? Transporting it any distance is out of the question, thus, the solution lies within the PSI's own research facilities. There, radioactive nuclides are produced on order to meet the demands of research, all according to when they are needed. To make sure this functions smoothly and that the needed radionuclides will be produced, a team of technicians stands ready around the clock.

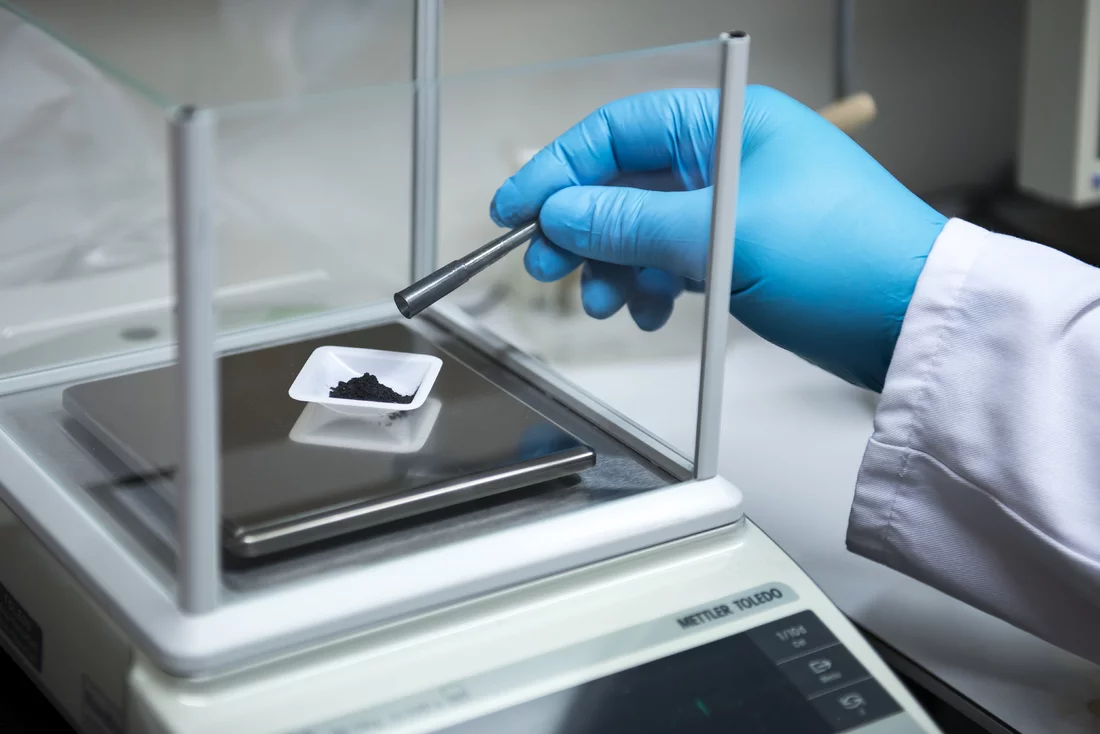

Anywhere other than the radiochemical laboratory of PSI West, someone might simply wipe away the little heap of grey-white powder, just under five millimetres wide, and wonder how these crumbs of chalk dust on a coin-sized disc of aluminium got there. Yet here, where Walter Hirzel's group works, that unimpressive little powder is anything but worthless: from it, through proton irradiation, artificial radionuclides are produced — substances whose atomic nuclei are unstable and, as a result, decay. Upon decay they release energy in the form of ionising radiation. Researchers at the Centre for Radiopharmaceutical Sciences (CRS) use the radionuclides for their experiments. The radionuclides are meant to be developed up to the point where they can be applied in drugs against various types of cancer. When such a radionuclide-bearing drug is injected into a patient, it is carried by the bloodstream directly to a tumour, which the radionuclide destroys with radiation.

Before such a radionuclide is ready for use, it takes several hours to process using facilities specially built for the purpose. Hirzel, a mechanical engineer who leads the Radionuclide Production and Maintenance Group, works together with his team to see that the radionuclides are produced as ordered for the experiments of various research groups. At the same time, nothing can be done without a stable, high-energy proton beam. This is generated in the proton acceleration facility of the PSI, where protons are accelerated to roughly one-third of the speed of light. A small portion of this beam is diverted for nuclide production. That is carried out with the help of various pieces of equipment, such as magnets that steer the beam and concentrate it into a radius of six to eight millimetres. The main beam goes on to be accelerated further and used for other experiments.

Hitting the mark, from many metres, with pinpoint precision

From its source to our irradition station, the proton beam covers a distance of around 33 metres and it strikes its target precisely in the middle

, Hirzel explains, adding: Sometimes I think it borders on the miraculous that we can hit such a small area.

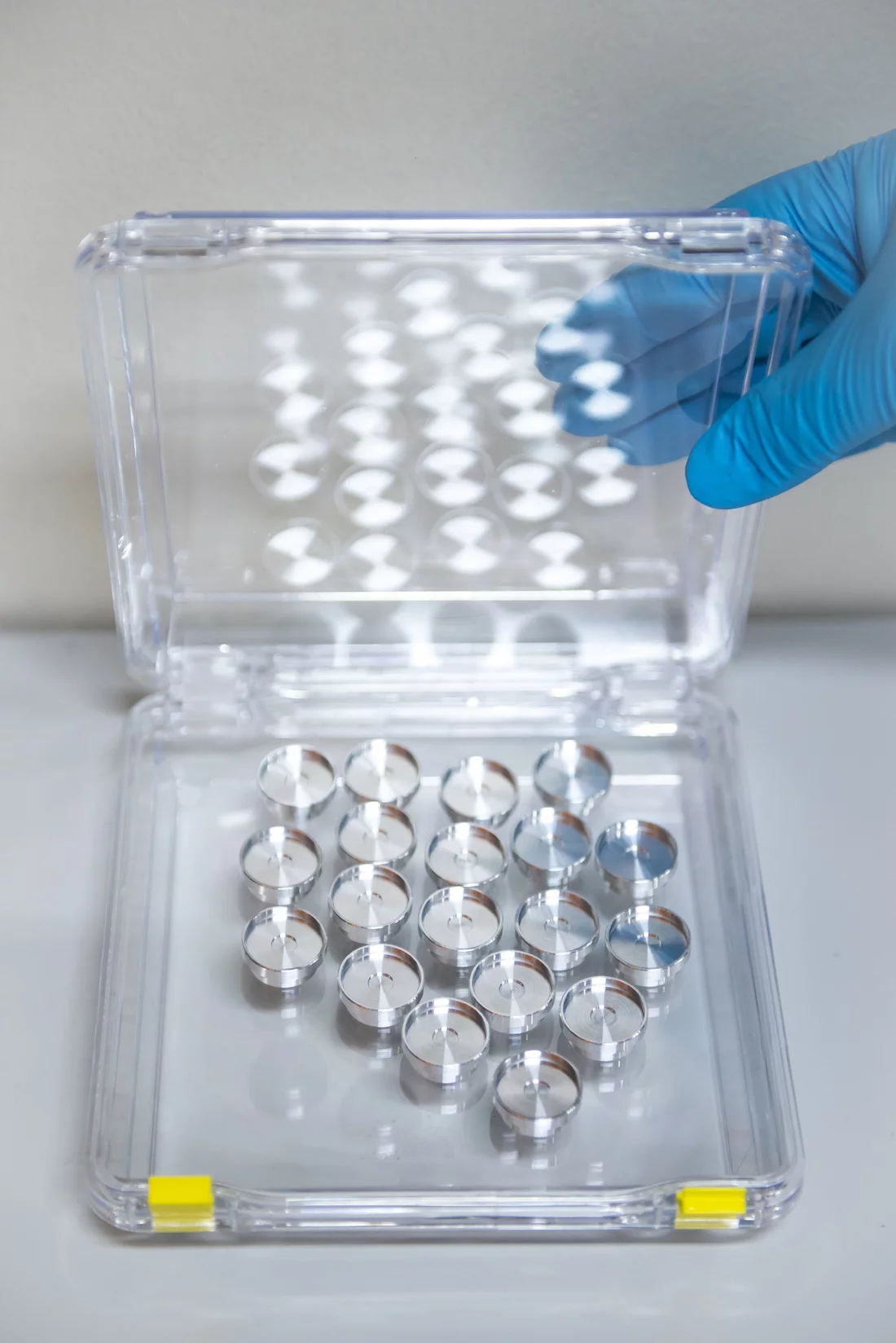

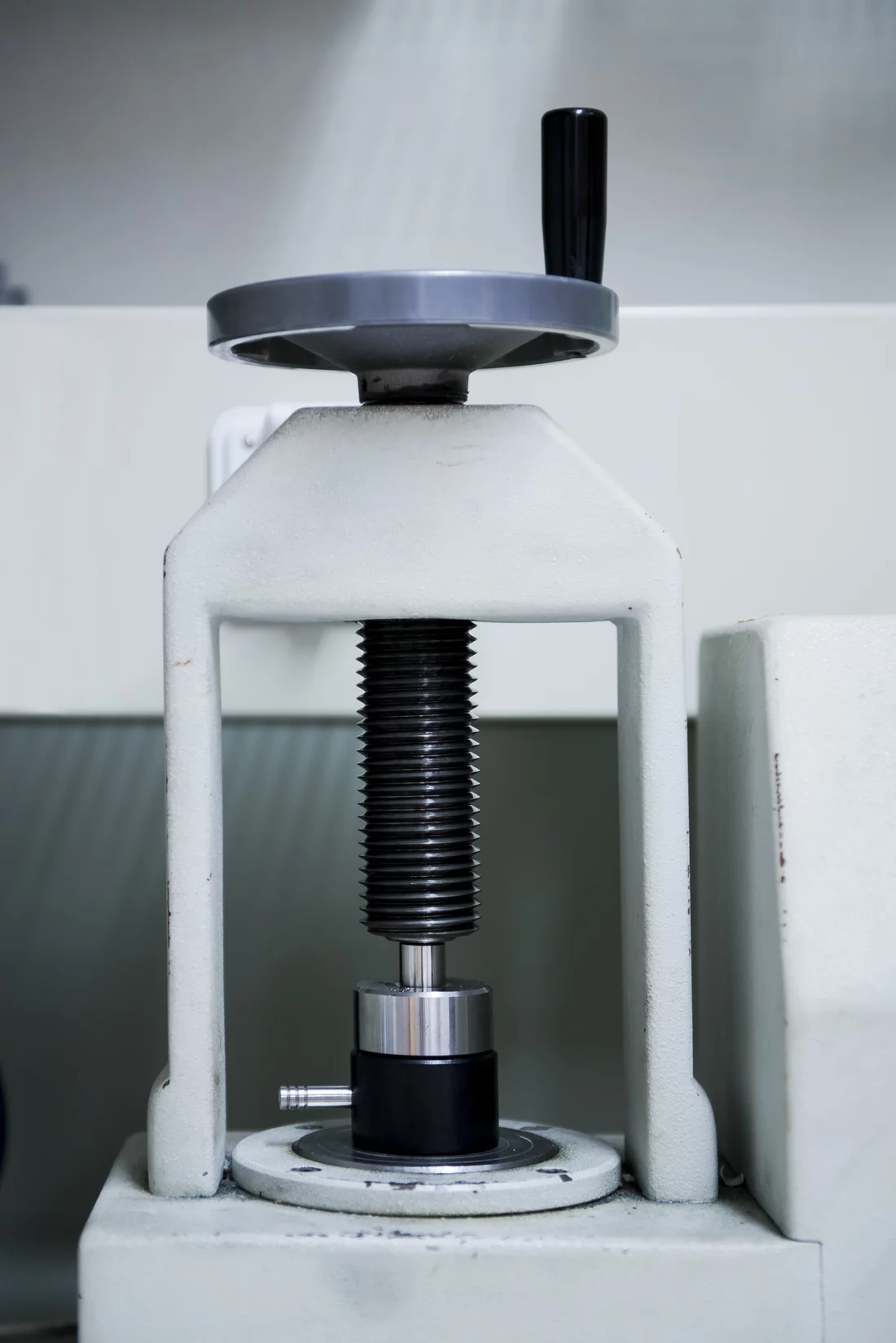

This small area is the cover of an aluminium capsule about the size of a thumbnail. It contains the precious grey-white powder from which the radionuclide will be produced. When the experts talk about the target, they mean the capsule together with its contents, clamped in a special mount and shielded from the outside in a target station in Hirzel's lab. The capsule is the proton beam's target and its ultimate destination. The beam strikes it with high energy for several hours, causing the target to get very hot inside. So the capsule is bathed in coolant and must be absolutely watertight. One drop of water inside it would be enough to generate steam and make the target burst. It could not be used anymore, so that the entire irradiation would have been for nothing. To make sure that doesn't happen, Hirzel's colleague Alexander Sommerhalder compresses every capsule, together with its precious contents, under a pressure of two tons. That'll hold!

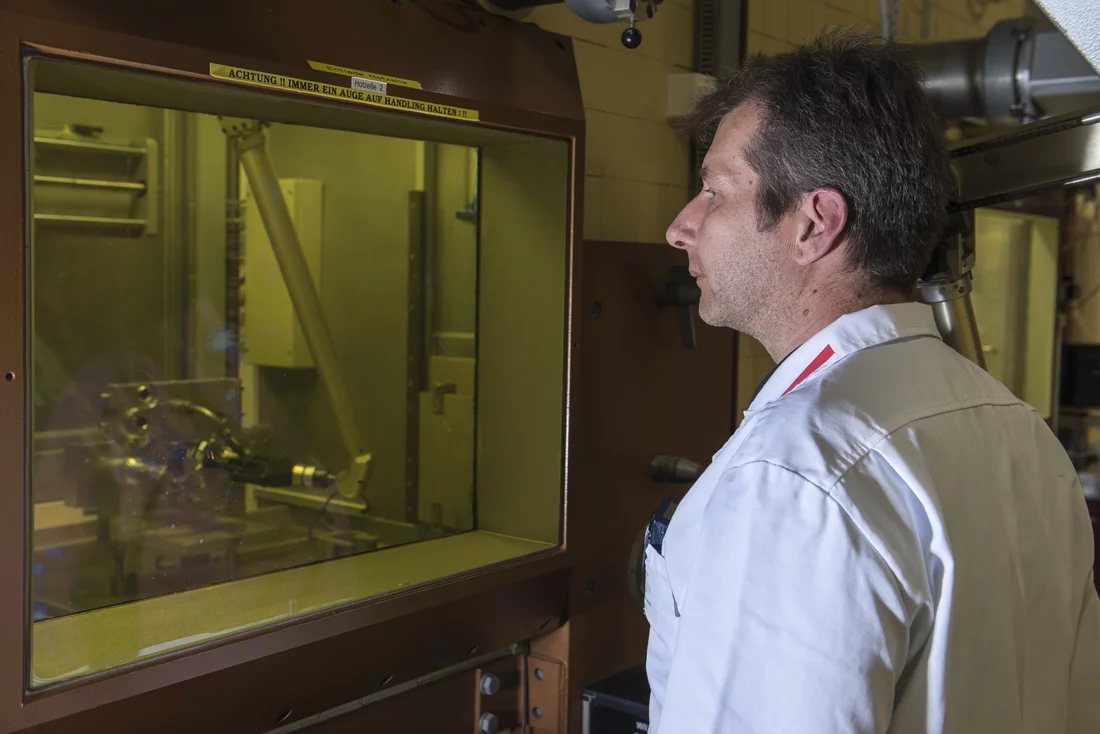

At the start of radionuclide production, when Sommerhalder compresses the capsule, he does not need to work behind special shielding because the precursor material is not yet radioactive. It's quite a different matter at the end of the whole process, when the irradiation is complete: Then he can touch neither the capsule nor its radioactive contents directly; every further step in the workflow takes place inside a so-called hot cell, shielded behind lead walls and panes of glass 60 centimetres thick.

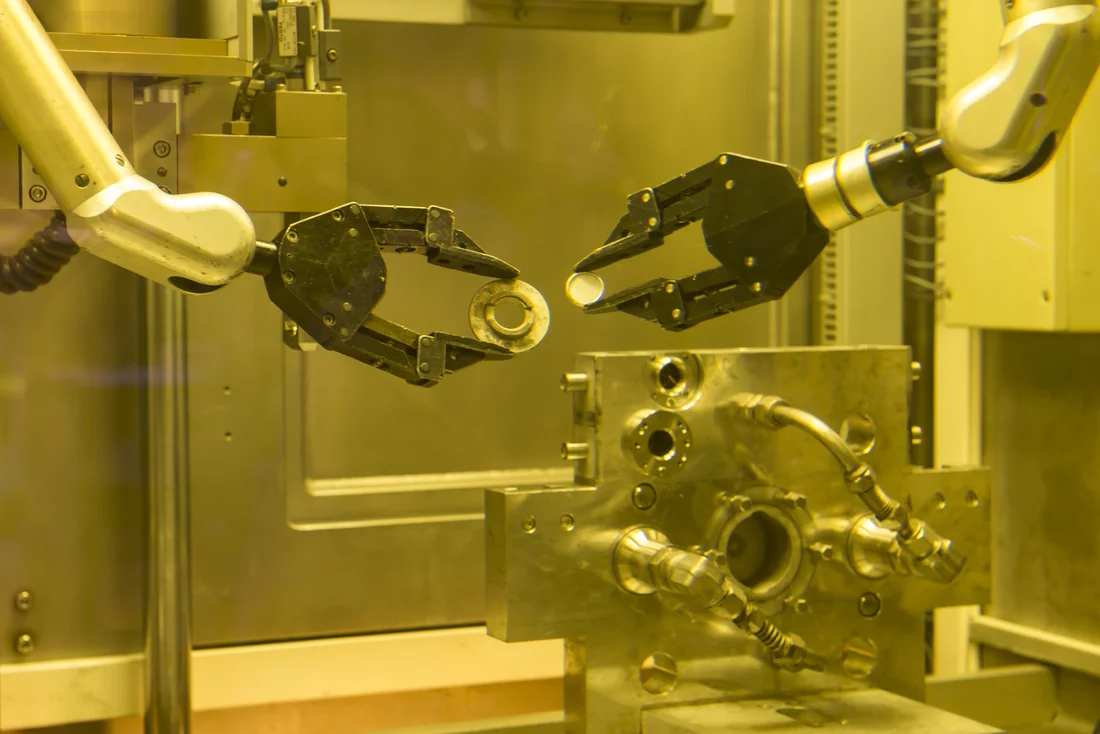

Giant grippers with fingertip finesse

After the capsule comes out of the target station, conveyed by an automatic transport system, it lands in the first work chamber of the hot cell. Superficially, it looks unchanged after the proton bombardment; only a small, circular burn mark in the middle of the cover hints at the kind of energy that has made its impact there. Sommerhalder must now remove this cover to take out the radioactive powder. That can only be done with the help of metre-long manipulators that would be a credit to any movie robot. The chunky gripping arms are inside the hot cell — in the radioactive area — and are controlled from the outside by means of tong-like handles. That requires some practice and coordination

, Sommerhalder says, while effortlessly manipulating the handles this way and that until he has opened the cover of the target capsule. The precision work begins, using the metallic gripping tongs, where the grey-white powder is transferred from the aluminium capsule into a small glass bottle. To do that, one has to grab the little capsule with one manipulator and empty its powdery contents into the bottle through a funnel. Anyone who misses the mark here wastes precious radionuclide. It's all a matter of experience

, Sommerhalder says as he skillfully opens the bottle's lid with the manipulators.

Moment of truth

Now comes the moment that Hirzel and his people are most interested in: an initial measurement of the sample's radioactivity. Did the irradiation work the way it was supposed to? Did the reaction proceed the way they wanted it to? They ask themselves these and other questions because the radiochemists tell us which radionuclide they need, which precursor material is required for that, and how we must irradiate it

, Hirzel explains. Yet that doesn't mean that everything proceeds exactly as theoretically predicted. Sometimes the radioactivity is weaker than expected, or too many reaction by-products are generated.

Several more steps follow after the first measurement, to obtain a clean radionuclide out of the radioactive powder, free from impurities. The next step involves chemical separation. For that, the glass vessel with the radioactive substance must be transferred to the next chamber of the hot cell, where a complicated apparatus with lots of hoses, pumps, probes, and valves stands. For every radionuclide, Hirzel and his team need to design and assemble a new apparatus. Each is one of a kind. Within them, the solid radioactive material is liquefied with acids, and the by-products filtered out — until the desired radionuclide is on hand in absolutely pure form. Hirzel: Even if we have started with maybe ten or twenty milligrams of precursor material, we sometimes have only a fraction of that in the end — an extremely small amount, but sufficient for the scientific experiments.

An ideal range of challenges for a generalist

For 13 years now, Hirzel has been the man for all cases at the CRS: when a machine is broken, a target capsule is needed, a chemical separation facility needs to be built, or radioactive waste is being recycled or removed. I came here initially in response to a newspaper ad

, the engineer recalls. The search was for an operations manager for nuclide production, and this made Hirzel curious. The variety of my duties and responsibilities here was something completely new. If I had to write down everything you need to be able to do for this position, it would end up being a long list. You need to be a bit of a generalist, enjoy hands-on work, and have ideas. This versatility appeals to me.

The researchers themselves greatly appreciate the work of Hirzel and his team, because without a properly functioning infrastructure, they couldn't get the radionuclides that they need. The engineer, on the other hand, appraises his group's share in the success of CRS rather modestly: It motivates me, when we can make a contribution and can say that we, together, have achieved a milestone in research. Our goal is to keep it running, so that others can go on working.

Text: Sabine Goldhahn

Proton beam

A proton beam doesn't come out of nowhere. At the proton acceleration facility of the PSI, protons are obtained from an ion source — so-called hydrogen plasma — and initially pre-accelerated with a Cockcroft-Walton accelerator. The proton beam is then further accelerated to an energy of 0.87 megaelectronvolts (MeV) and guided under vacuum conditions to the injector cyclotron, where the energy is increased to 72 MeV. As a result, the beam already reaches a speed of approximately 110,000 km/s — roughly one-third of the speed of light. Around two percent of this beam is diverted for the production of radionuclides. The rest continues on its way: In the next step, the protons are accelerated in the large ring cyclotron until they attain a final speed of 80 percent of the speed of light. Their energy at that point is equivalent to 590 MeV. With these protons, neutrons and muons are generated, which are used for a number of different experiments.Additional information

- The article

Targeting cancer

provides an overview of the work of the Center for Radiopharmaceutical Sciences. - The articles

Developing a new drug against thyroid cancer

andMedicines made to order with pinpoint precision

describe the development and production of a drug at the Center for Radiopharmaceutical Sciences. - A new method that would channel radioactive substances right into the cell's nucleus is described in the article:

Hitting cancer from the inside

- Article on how PSI researchers are developing efficient procedures for producing radionuclides used in medical diagnostics:

Designer nuclide for medical applications

.

Contact

Walter Hirzel, Head of the Infrastructure Group at the Centre for Radiopharmaceutical Sciences of the Paul Scherrer Institute PSI, ETH Zurich, and the University Hospital of ZurichTelephone: +41 56 310 43 13, e-mail: walter.hirzel@psi.ch