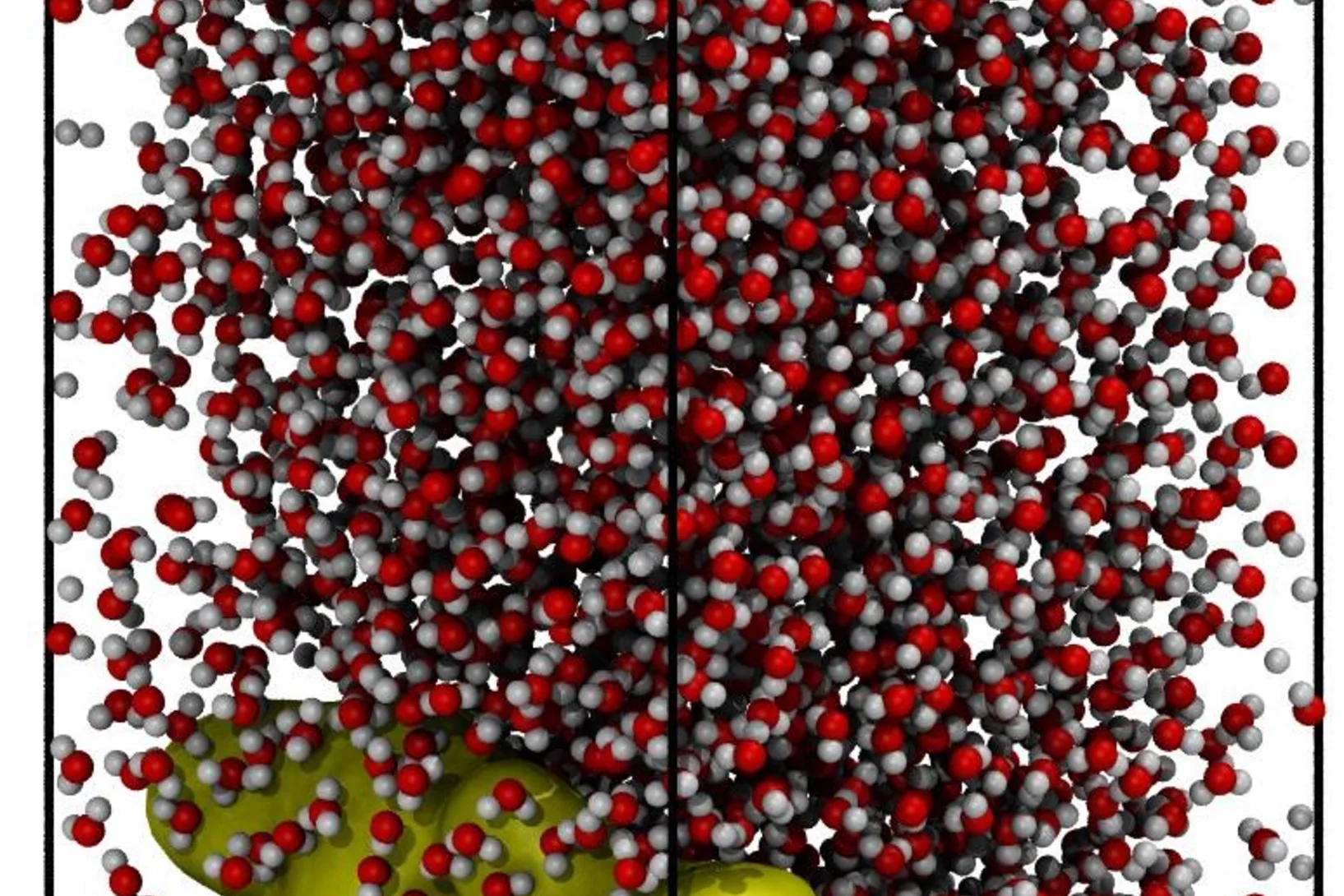

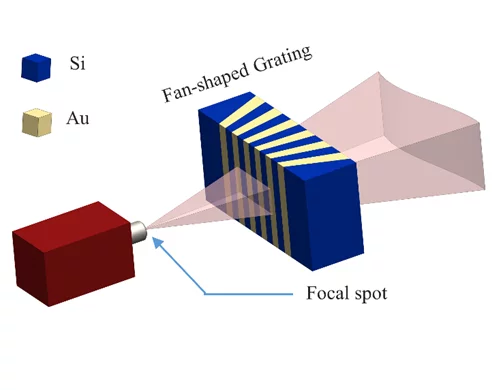

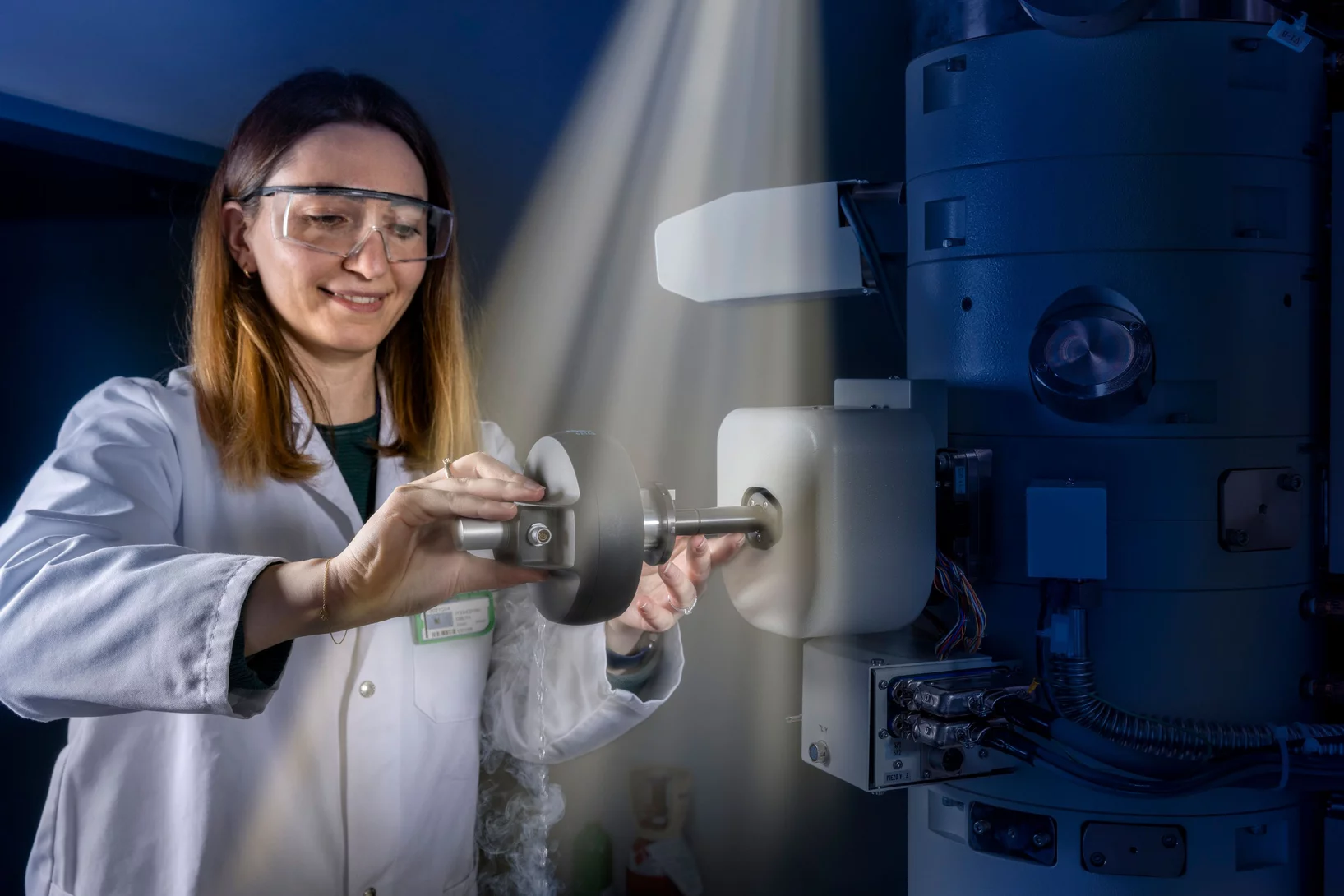

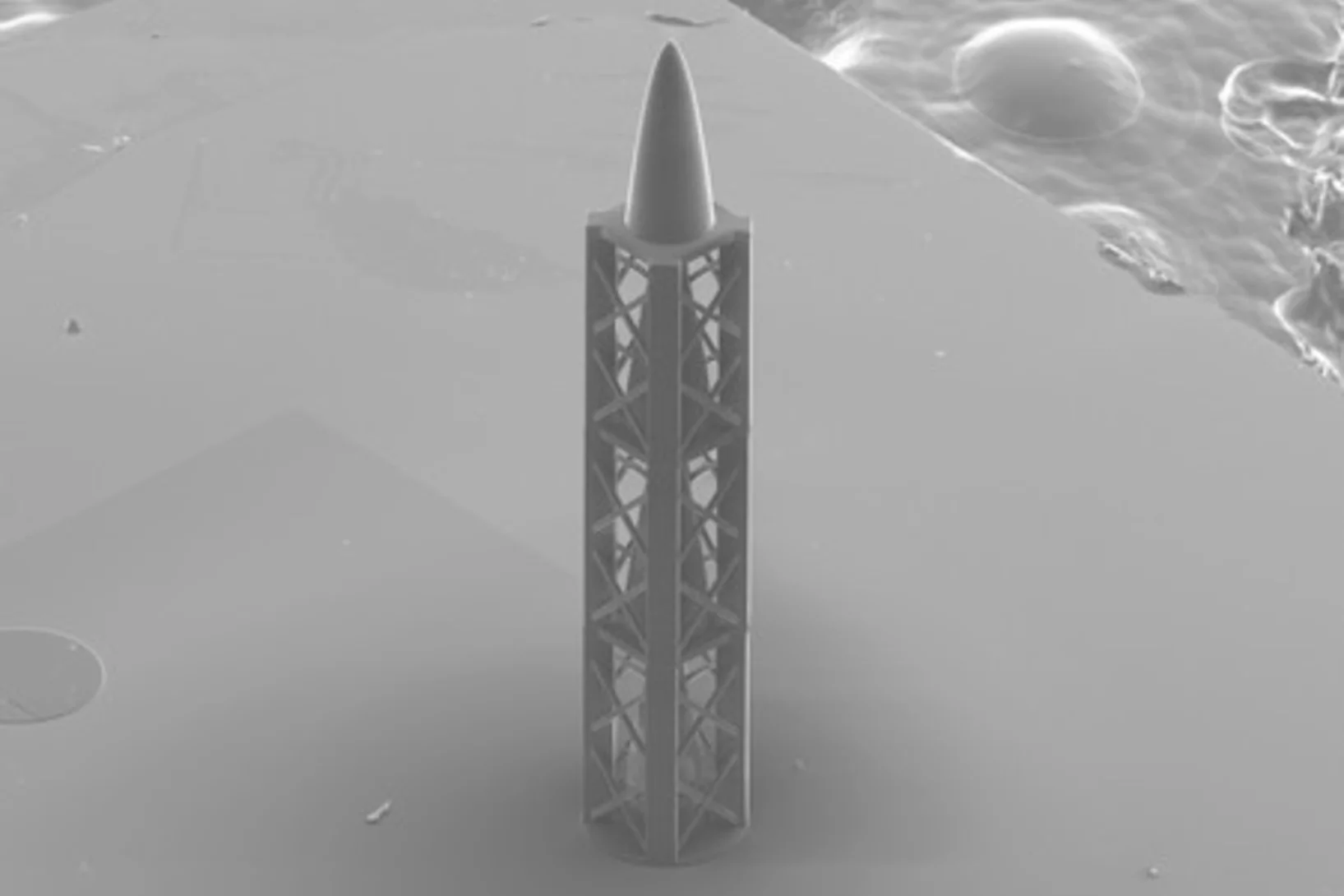

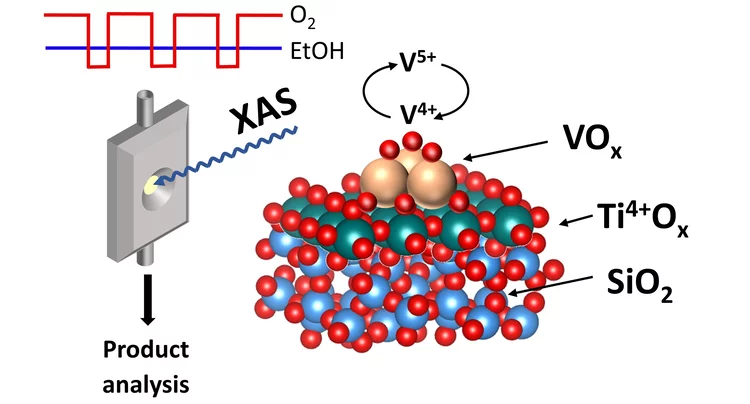

La plus récente grande installation de recherche du PSI génère de très courtes impulsions de rayons X, ayant les propriétés du laser. Cela permet aux chercheurs de suivre des processus extrêmement rapides tels que l'apparition de nouvelles molécules lors de réactions chimiques, de déterminer la structure détaillée de protéines vitales ou de comprendre la composition exacte de matériaux. Les chercheurs pourront ainsi obtenir des informations auxquelles les méthodes actuelles ne permettent pas d'accéder. Les connaissances acquises élargissent notre compréhension de la nature et débouchent sur des applications pratiques telles que de nouveaux médicaments, des processus plus efficaces dans l'industrie chimique ou de nouveaux matériaux en électronique.

Plus d'information sur le sujet SwissFEL